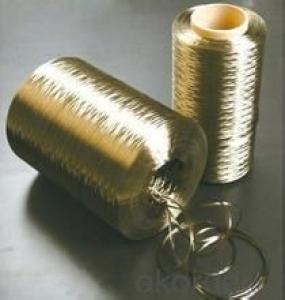

High-Quality Basalt Fiber Twill Fabric with Fiberglass Rovings - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Twill Fabric Description:

Industrial technology of basalt fiber fabric, is woven from excellent permeability and tapability basalt roving or textile fabric, monofilament diameter is generally 5.5-9μm. It is particularly applicable in the field of high temperature and corrosion resistance. It can combine quite well with the resin, rubber and other organic materials.

Fabrics includes:

1.Basalt fiber unidirectional fabric

2.Basalt fiber roving cloth

3.Basalt fiber mesh cloth

Product Features:

1. high strength low cost

2. fire resistance

3. good compatibility with resin

4. ideal substitute of carbon fabric

Basalt fiber yarn for textile specificaiton:

specification | width(cm) | organization | by the density | g/ m² |

BW-0.8-96 | 96-100 | 8HS | 16.5±1 | 800-850 |

BW-0.4-96 | 96-100 | 4HS | 18±1 | 420-450 |

BW-0.35-100 | 100-120 | PLAIN | 11±1 | 380-400 |

BW-0.2-100 | 100-120 | PLAIN | 17±1 | 200-220 |

packages :with pallets in carton

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: Main use of glass fiber

- Traffic. Among them, but the toughness of the same plastic will decrease, but after 1990s, with the global glass fiber modified plastics improves, glass fiber plain cloth has been widely used in various field. Because it is widely used in various field.

- Q: Can you describe the production process of glass fiber and the production process?

- There are clay crucible method-the most primitive method; platinum substitute crucible, with the raw materials for the production of glass fiber glass and the poor quality of products and pool kiln method, with the process of high energy consumption, which is banned, where the the raw material is powder mixture with pyrophyllite. Platinum crucible method is widely used at present. Tank furnace method" is the most advanced technology and the main raw material is waste broken glass

- Q: Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q: What is glass fibre reinforced plastic

- Glass fiber reinforced plastic is a kind of material composited by glass fiber and matrix composite with its strength improves.

- Q: How to make glass fiber pipe

- If you ask what is the glass fiber sleeve such as epoxy or phenolic tubes, this is a complex question.

- Q: What can glass fiber grid do in road engineering?

- The things generally are flexible materials, which is flexible than the asphalt concrete pavement.

- Q: What are the types of glass fiber yarns?

- Yarn is usually used for glass fiber window?screening.

- Q: What kind of knife can used to cut glass wool cloth?

- The mix proportion of epoxy resin and mortar is that 6101epoxy resin: ethylenediamine: cement: sand is equal to 100:15:8:200:500. 1 base dispose, 1)a vertical fissure is formed along the crack gouge, vertical cracks cut into 2 surface treatment, Siyou cloth with its surface sticking epoxy base fluid and glass silk cloth is used for surface treatment ( in which oil used is epoxy liquid, and cloth is glass?silk cloth). 1) process of glass silk cloth. Glass cloth generally usually made by alkali-free glass fiber is twistless roving woven cloth. Wetting agent are added in the production process of glass silk cloth. As wetting agent contains grease and wax which will impact the combination of epoxy base fluid and glass silk cloth, it is necessary to remove oil and wax on glass silk cloth in order to make epoxy base fluid immerse in glass fiber, improving the bonding effect. The method for removing wax and oil is to place glass silk cloth in boiling water containing with soda for an hour, then you should blanching it with clean water. the way to judge whether there is oil and wax on glass silk cloth is to touch and feel it. If you feel like it is not greasy, it is clean. After removing oil and wax, glass silk cloth losts its original white and brightness appearance and its weight also reduces correspondingly. 2) paste process. When pasting, you should brush epoxy resin base fluid evenly on the paste face, then you should brush the second layer with the same way.

- Q: how to produce glass?reinforced?plastics grating

- It is formed by glass fiber after extrusion.

Send your message to us

High-Quality Basalt Fiber Twill Fabric with Fiberglass Rovings - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords