Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Basalt fiber roving is collective beam,which combine stranded parallel protofilament with sub-thread thread parallel protofilament in no woven condition.

specifications :

1.Tensile strength of the roving 7-13μ Woven roving ≥ 0.65N/Tex

2.Elastic modulus is ≥ 95GPa

3.Elongation at break ≥ 2.6%

4.High temperature and light resistance.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns.

Rovings are manufactured according to Technical Specifications 5769-026-00204990-2005.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns. Complex yarns for assembled roving are made of basalt crumb.

Example of assembled roving: BC11320W-76(64)

B – raw material – basalt crumb.

C –continuous yarn.

11 – nominal diameter of a simple yarn, μm.

320 – nominal linear density of roving, tex.

W – purpose of roving: W – for weaving.

76 – type of silane sizing.

64 – nominal linear density of a complex yarn, composing roving.

Field of application:

1. Manufature of basalt fabrics;

2. Manufacture of basalt plastics;

3. Manufacture of bodies of rotation: pipes for chemical, oil and gas industries, pressure relief pipes, tanks (made by winding) for storage and transportation of chemically active substances, waterm combustive-lubricating products.

4. For reinforcement of plastics and concrete.

5. In production of geotextile nets and canvases, serving for reinforcing of asphaltic concrete pavement, by improving durability and split-resistance.

packages :

in carton with pallets

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: Does toughened glass and glass?reinforced?plastics are the same?

- It should be said that they are the same material.

- Q: An introduction to glass fiber cloth

- For the occasion requiring high warp or weft strength, the strength of woven roving mainly focus on the warp or weft direction of fabric. Roving roving is composed of parallel raw silk or parallel filaments. According to glass composition, twistless roving can be divided into unidirectional cloth E-GLASS alkali-free glass twistless roving and C-GLASS medium alkali glass twistless roving. Glass fiber woven roving is twistless roving plain fabric and is an important base material for pasting glass?reinforced?plastics. Moreover, it is also unidirectional weft cloth.

- Q: An introduction to glass fiber geogrid

- It is net?structure material woven through a certain method. In order to protect the glass fiber and improve the overall performance, it is geotechnical base material with excellent performance formed by a special coating treatment process. Glass fiber alkali free twistless roving is the main material of glass fiber geogrid.

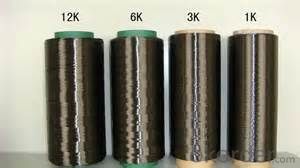

- Q: What are the types of glass fiber yarns?

- According to different diameter, glass fiber yarn can be divided into yarn and roving general. The yarn is usually used for producing curtains.

- Q: Main characteristics of glass?reinforced?plastics grating

- powerful, corrosion resistance, beautiful.

- Q: What is the material of glass steel? How to make it?

- Glass fiber reinforced plastic is a kind of composite material. It is common in everyday life. As a typical composite material, it is made by glass fiber and epoxy resin. In general, the glass fiber should be woven into a glass cloth, and then mix with the epoxy resin, the glass fiber reinforced plastic can be made after expoxy resin solidition. Epoxy resin itself is toxic, but the chemical properties is stable, and it is not harmful to human after solidation.

- Q: What is glass fiber extrusion

- Glass fiber extruding machine set can be used to produce different shapes of glass fiber reinforced plastics in different shapes, which can be formed by the oven traction machine oil pump station and so on.

- Q: How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

Send your message to us

Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords