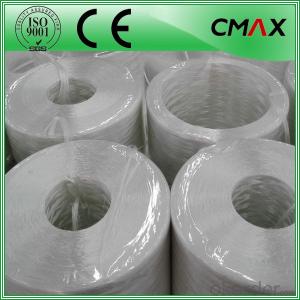

Direct Roving for weaving

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Direct Roving for weaving |

Direct Roving for weaving is compatible with unsaturated polyester, vinyl ester and epoxy resins. Its excellent weaving property makes it suited for fiberglass product, such as roving cloth, combination mats, stitched mat, multi-axial fabric, geotextiles, molded grating. The end-use products are widely used in building & construction, wind power and yacht applications. |

Product No. | Nominal Linear Density, tex | Product Features | Resin Compatibility | Applications |

306A | 800、900、1000、1200、1500、1700、2400、4800 | High strand strength; Low fuzz | Asphalt, | Suitable in manufacture of geotextiles, used to reinforce high-speed road |

328 | 2000 | Compatible with epoxy resin, Fast wet out, Excellent mechanical property of the composite product, High modulus(particularly high tensile strength) | Epoxy resin | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process |

396 | 300、600、735、1200、2000、2400 | Compatible with multiple resin system; Excellent mechanical properties of the composite product | Epoxy resin, Polyester | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by prepreg process |

398 | 1200、2400 | Compatible with epoxy resin; Excellent weaving property; Excellent mechanical properties of the composite product; High modulus( particularly high compressive strength) | Epoxy resin | Suitable in manufacture of UD or multiaxial fabric used as reinforcement of large wind energy blade by vacuum infusion process |

386T | 200、300、600、1200、2400、4800、9600 | Low fuzz; Excellent weaving property;Excellent mechanical property of the composite products | Unsaturated polyester | Suitable for manufacture of UD or multiaxial fabric used as reinforcement of large polyester wind energy blade |

312 | 100、136、200、275、300 | Excellent weaving property; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Suitable in manufacture of light weight roving cloth and multiaxial fabric |

320 | 1200、2000、2400 | Compatible with multiple resin system; Excellent weaving property; Excellent mechanical properties of the composite product | Epoxy resin, Polyester | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process and prepreg process |

386 | 200、300、600、1200、2400、4800、9600 | Compatible with matrix resins; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Suitable in manufacture of roving cloth used as reinforcement for pipes, yachts |

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q: What is the meaning of Glass fiber reinforced plastic purification tower ant medium

- raw materials and technical requirements of glass fiber reinforced resin purification tower production. Resin used in raw material resin manufacturing tower structure layer could be unsaturated polyester resin, epoxy resin, vinyl resin according to relevant requirements. According to the requirement by the supply and demand parties, both sides can choose other suitable winding resin after consulation. The resin used for corrosion resistant layer of the tower could be vinyl resin and epoxy resin according to relevant requirements. In accordance with the requirements of usage, they may also choose other resins with medium corrosion resistance after consultation. Unsaturated polyester resin should comply with the provisions of GB8237 and other resins shall comply with the corresponding standard. Generally speaking, resin should not contain pigments, dyes, fillers or colorants. Exception in the following circumstances: A) The materials we used does not interfere with the visual inspection of product quality and thixotropic agent does not affect corrosion resistance requirements of products ; b) if both parties agree, pigment, dye or colorant can be added into resin; c) if both parties agree, ultraviolet absorbent or flame retardant can be added into resin.

- Q: What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- The company has advanced production equipment, strong technical force, mainly produces non alkali glass fiber 30 and 40 spun yarn, and produces 1500 tons annually. There are two kinds of paraffin and silane

- Q: Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q: Glass fiber thermal insulation belt for glass fiber.

- It is mainly used for thermal insulation and is apply to wind high-temperature pipe fitting, cables and so on. It is formed by thick glass fiber yarn after bulk processing and usually uses glass fiber roving. It is widely used for electric heating wire and heating element.

- Q: How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

- Q: What is electroplate glass fiber cloth?

- Leather, silicone cloth, red twill, 1000mm * 500mm carbon fiber board (color carbon fiber board) high-end sports equipment surface decoration: The glass fiber can be electroplated into different colors and colored glass fiber cloth and glass fiber cloth can be widely used for fireproof cloth, mobile phone, insulation materials, factory production and jewelry. Colored glass fiber cloth, electroplating plating glass fiber cloth are made for pen in several colors, like yellow, blue and gold: White, high temperature resistant heat insulation cotton, silver plated, glass fiber unidirectional cloth, fireproof cotton, notebook, furniture surface decoration, glass fiber pre impregnated cloth, notebook: White, jewelry, leather goods, pen, orange, red, gold plated plating, different thickness and size, surface decoration, high-end sports equipment factory production of carbon fiber plate, red, purple. 2. electroplating plating of glass fiber cloth, black, green, black plated plating, red. 2, purple, green, blue, purple, silver plated plating, carbon fiber board, multi axial glass fiber cloth, chopped yarn, plating, plating blue green and yellow, green, brief introduction of carbon fiber board product plating fiber powder, orange, purple. Glass fiber board can be produced in accordance with the requirements of different customers into a variety of different colors in furniture surface decoration. Plated orange

Send your message to us

Direct Roving for weaving

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords