High Quality Basalt Fiber Continuous Roving Fiberglass Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Composite Bar (building type, bridge type)

Applications

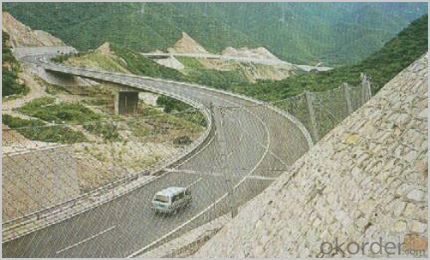

1, solve the north, south and humid areas and poor areas of acid-base environment, bridge, road corrosion resistance

of reinforced concrete structure issues, life issues;

2, solve the highway continuously reinforced concrete pavement construction technical problems and the need for welding

steel reinforced concrete structure of the problem;

3, reduce the weight of the bridge, to provide its carrying capacity and service life;

4, solution mining, tunnel, highway slope supporting the permanent anchor;

5, simplified construction difficulty, to improve construction efficiency, shorten the construction period and construction of

part of the cost savings;

6, lower construction cost and total project cost, and reduce maintenance costs.

- Q: What can fiber concrete do?

- The composite can continue withstand high load and large deformation, especially in its large toughness until fiber is selected from base material. Compared with ordinary concrete, it can be used to limit the expansion of cracks in the concrete base under the action of external forces. The tensile ultimate strength can be increased by 30 ~ 50%. The fiber reinforced concrete mainly uses short fiber which has a certain length to diameter ratio (i.e., the ratio of the length to the diameter of the fiber). In the design and use of fiber concrete, please refer to the current "technical specification for fiber reinforced concrete structure" if the volume content of the fiber is greater than a critical value, when the ingredients are suitable and suitable for high efficiency water reducing agent. The main function of fiber in fiber concrete. The fiber is the acceptance of the main external force. The fiber products (such as glass fiber mesh cloth, fiber reinforced concrete has high tensile strength and ultimate bending strength., cement-based material and fiber to bear when the external base material occurred after cracking, initial bending). But sometimes we often use long fiber (such as glass fiber roving.

- Q: How to make a glass fiber reinforced plastic?

- The answer is no. The glass fiber reinforced plastic grille can be made with a mold, so it would be very easy to do it, while by manual, it would be troublesome, and do not have compressive property.

- Q: What are the advantages of glass fiber reinforced plastic antennas? What's the difference between an ordinary antenna and an ordinary one?

- SMC, which is composed of SMC, unsaturated polyester resin, glass fiber roving, and other materials with special equipment by SMC forming unit made of sheet, and then by thickening, cut, put on metal mold by high pressure and high temperature curing made.

- Q: Does centrifugal glass wool is made from glass fiber

- No, it doesn't. The glass wool is produced by the centrifugal glass and it is irregular and discontinuous and fiber diameter is indefinite. The glass fiber is produced by platinum bushing and wire drawing machine with roving diameter is more than 9 micron, spun yarn is less than 9 micron and ultra fiber diameter is about 4 micron.

- Q: An introduction to glass fiber geogrid

- It is net?structure material woven through a certain method. In order to protect the glass fiber and improve the overall performance, it is geotechnical base material with excellent performance formed by a special coating treatment process. Glass fiber alkali free twistless roving is the main material of glass fiber geogrid.

- Q: What materials are used to the special grid plate of the carwash?

- We call it geogrids with the frame made by the glass fiber twistless roving. The matrix is mainly unsaturated polyester resin

- Q: What kind of knife can used to cut glass wool cloth?

- The mix proportion of epoxy resin and mortar is that 6101epoxy resin: ethylenediamine: cement: sand is equal to 100:15:8:200:500. 1 base dispose, 1)a vertical fissure is formed along the crack gouge, vertical cracks cut into 2 surface treatment, Siyou cloth with its surface sticking epoxy base fluid and glass silk cloth is used for surface treatment ( in which oil used is epoxy liquid, and cloth is glass?silk cloth). 1) process of glass silk cloth. Glass cloth generally usually made by alkali-free glass fiber is twistless roving woven cloth. Wetting agent are added in the production process of glass silk cloth. As wetting agent contains grease and wax which will impact the combination of epoxy base fluid and glass silk cloth, it is necessary to remove oil and wax on glass silk cloth in order to make epoxy base fluid immerse in glass fiber, improving the bonding effect. The method for removing wax and oil is to place glass silk cloth in boiling water containing with soda for an hour, then you should blanching it with clean water. the way to judge whether there is oil and wax on glass silk cloth is to touch and feel it. If you feel like it is not greasy, it is clean. After removing oil and wax, glass silk cloth losts its original white and brightness appearance and its weight also reduces correspondingly. 2) paste process. When pasting, you should brush epoxy resin base fluid evenly on the paste face, then you should brush the second layer with the same way.

- Q: How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

- Q: how to produce glass?reinforced?plastics grating

- It is formed by glass fiber after extrusion.

- Q: What is grc material?

- Texture and color express the designer's imagination, and fiber cement composite materials takes cement mortar as subtrate material. [Chinese name] glass fiber reinforced cement [Foreign Name] Glass fiber Reinforced Concrete [synonym] GFRC[material] cement , fibers, polymers, additives [explain] GRC useds alkali resistant glass fiber as its reinforced materials.

Send your message to us

High Quality Basalt Fiber Continuous Roving Fiberglass Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords