Auto-climbing bracket ACB-100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

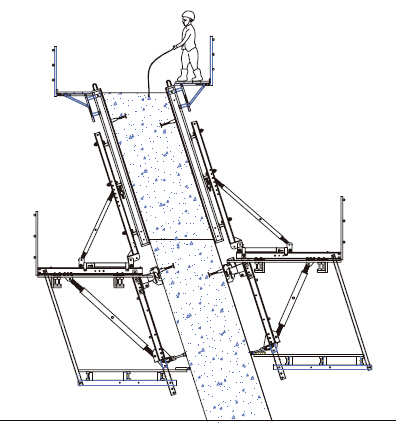

Auto-climbing Bracket ACB100 & ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q: How does steel formwork handle concrete curing time?

- Steel formwork is an ideal choice for handling concrete curing time due to its durability and strength. It can withstand the pressure exerted by fresh concrete during the curing process without deforming or breaking, ensuring that the concrete retains its desired shape and strength. Additionally, steel formwork allows for faster curing times as it provides excellent heat dissipation, allowing the concrete to cool down uniformly and solidify quickly. This reduces the overall construction time and increases efficiency.

- Q: How does steel formwork affect the overall efficiency of the construction process?

- The overall efficiency of the construction process can be greatly enhanced through the utilization of steel formwork, primarily due to its durability, versatility, and ease of use. To begin with, the strength of steel formwork is exceptional, enabling it to withstand the weight and pressure of concrete without bending or warping. Consequently, construction can be expedited, as there is no need to wait for repairs or replacements to be made to the formwork. Additionally, the ability to reuse steel formwork multiple times reduces the time and cost associated with constantly purchasing new materials. Furthermore, steel formwork is highly adaptable and can be easily customized to meet the specific requirements of different construction projects. It can be effortlessly adjusted, cut, and welded to create a variety of shapes and sizes, thereby allowing for greater design flexibility. This adaptability also facilitates quicker construction, as the formwork can be swiftly modified to accommodate changes in the construction plans. Moreover, steel formwork is designed with user-friendliness in mind, making assembly and dismantling easier and faster for construction workers. Compared to materials such as wood or aluminum, steel formwork is lightweight, reducing the physical effort required during installation and removal. The standardized components of steel formwork also contribute to a more efficient and less time-consuming assembly process. Additionally, the use of steel formwork improves quality control and accuracy in construction. The smooth surface of steel formwork ensures a consistent finish on concrete structures, minimizing the need for additional finishing work. This not only saves time but also enhances the overall aesthetics of the construction project. In conclusion, the utilization of steel formwork significantly enhances the efficiency of the construction process by reducing construction time, minimizing material waste, and improving the quality and accuracy of the final structures. Its durability, versatility, and ease of use make it an ideal choice for construction projects of all sizes.

- Q: Are there any specific design considerations for steel formwork?

- Yes, there are several specific design considerations for steel formwork. Firstly, the design should take into account the load-bearing capacity of the steel formwork. Steel has high strength and rigidity, but it is important to ensure that the formwork is designed to withstand the loads imposed by the concrete during pouring and curing. Secondly, the design should consider the dimensional accuracy required for the concrete structure. Steel formwork should be designed to provide precise dimensions and smooth finishes to ensure the desired shape and appearance of the final concrete structure. Thirdly, the design should incorporate proper connection details for assembling and dismantling the steel formwork. It is important to ensure that the formwork can be easily assembled and disassembled, as this can significantly impact the construction timeline and efficiency. Additionally, the design should consider the ease of handling and transportation of the steel formwork. Steel formwork components should be designed to be lightweight and easily maneuverable, making it easier for construction workers to handle and transport them on site. Furthermore, the design should take into account the durability and longevity of the steel formwork. Steel is known for its high durability and resistance to corrosion, but proper protective coatings or treatments should be specified to ensure the longevity of the formwork and prevent any degradation over time. Lastly, the design should consider any specific requirements or constraints of the project, such as special architectural features, complex geometries, or unique structural elements. These considerations may require custom design solutions to meet the specific needs of the project. Overall, the design considerations for steel formwork involve load-bearing capacity, dimensional accuracy, connection details, ease of handling and transportation, durability, and any project-specific requirements.

- Q: How does steel formwork affect the overall construction site safety measures?

- Steel formwork can have a significant impact on the overall construction site safety measures in several ways. Firstly, steel formwork is known for its high strength and durability, which ensures stability and structural integrity during the construction process. This reduces the risk of accidents such as collapses or structural failures, enhancing the safety of workers and the site as a whole. Additionally, steel formwork offers better fire resistance compared to other types of formwork materials. This characteristic can prevent or slow down the spread of fire, providing extra time for workers to evacuate the site safely and for emergency services to respond effectively. It also reduces the risk of fire-related accidents, protecting both human lives and the surrounding environment. Another safety benefit of steel formwork is its ability to withstand extreme weather conditions, such as strong winds or heavy rain. This resilience reduces the likelihood of formwork damage or failure, ensuring the safety of workers and preventing potential accidents caused by adverse weather. Furthermore, steel formwork is often designed with built-in safety features, such as handrails and platforms, to provide secure working surfaces for construction workers. These features allow workers to perform their tasks safely at heights, reducing the risk of falls and injuries. Lastly, steel formwork is reusable and requires minimal maintenance, which contributes to the overall site safety. The use of reusable formwork reduces waste and clutter, creating a cleaner and more organized working environment. This, in turn, minimizes the risk of accidents caused by tripping or falling over debris. In conclusion, steel formwork positively affects the overall construction site safety measures by providing stability, fire resistance, weather resistance, built-in safety features, and a cleaner working environment. These benefits reduce the risk of accidents, ensure the safety of workers, and contribute to the successful completion of construction projects.

- Q: How does steel formwork compare to aluminum formwork in terms of performance?

- Steel and aluminum formwork are commonly used materials in the construction industry to create temporary molds or structures that hold concrete in place until it becomes solid. When comparing these materials, it is important to consider their performance aspects. In terms of performance, steel formwork is known for its strength and durability. It can withstand heavy loads and rough handling, making it suitable for heavy-duty applications. Steel formwork also maintains its shape during the concrete pouring process, resulting in accurate finishes. It can be easily customized to meet project requirements. On the other hand, aluminum formwork is preferred for its lightweight nature. It is easy to handle, transport, and assemble, reducing labor costs and construction time. It also has excellent corrosion resistance, making it suitable for coastal areas or humid environments. Additionally, aluminum formwork provides a smooth surface finish on the concrete, requiring minimal treatment. The choice between steel and aluminum formwork depends on the specific project requirements. Steel formwork is ideal for projects with heavy loads or high reuse needs due to its strength and durability. On the other hand, aluminum formwork is a better choice for projects that require quick assembly, easy handling, and a smooth surface finish. Ultimately, the selection of formwork should be based on a careful evaluation of the project's needs, budget, timeline, and other factors such as cost, maintenance, and environmental impact.

- Q: How does steel formwork affect the overall seismic performance of a structure?

- Steel formwork can significantly affect the overall seismic performance of a structure in several ways. Firstly, steel formwork provides a rigid and robust temporary support system during the construction process. It ensures proper alignment and placement of concrete, which is crucial for the structural integrity of the building. By providing accurate and precise formwork, steel helps in creating a well-designed structure that can withstand seismic forces. Secondly, steel formwork enhances the strength and stiffness of the concrete structure. Steel is known for its high tensile strength, which allows it to resist the lateral forces induced by an earthquake. This increased strength and stiffness can help in reducing the deformation and damage caused by seismic activities. Additionally, steel formwork can prevent the formation of cracks and improve the overall durability of the structure. Moreover, steel formwork can contribute to the ductility of a building. Ductility is the ability of a structure to undergo large deformations without sudden failure. Steel formwork allows for the creation of reinforced concrete elements, such as beams and columns, which can absorb and dissipate seismic energy through plastic deformations. This plastic behavior helps in redistributing the seismic forces and reducing the overall vulnerability of the structure. Furthermore, steel formwork can facilitate the use of innovative structural systems like steel plate shear walls, moment frames, or braced frames. These systems are designed to provide enhanced seismic resistance by dissipating energy and controlling the deformations during an earthquake. Steel formwork allows for the precise fabrication and installation of these systems, ensuring their effectiveness in improving the seismic performance of the structure. In conclusion, steel formwork plays a crucial role in enhancing the overall seismic performance of a structure. It provides temporary support, enhances the strength and stiffness of concrete, improves ductility, and enables the use of innovative seismic-resistant systems. By incorporating steel formwork in the construction process, engineers can create structures that are better able to withstand the destructive forces of earthquakes.

- Q: Can steel formwork be used for sports complex construction projects?

- Yes, steel formwork can be used for sports complex construction projects. Steel formwork is a versatile and durable option for creating the desired shapes and structures required for sports complexes. It can be used to construct various elements of the complex, such as walls, columns, beams, and slabs. Steel formwork offers high strength and stability, allowing for larger spans and higher load-bearing capacity, which are often necessary for sports facilities. Additionally, the smooth finish achieved with steel formwork helps to create a professional and aesthetically pleasing appearance. Overall, steel formwork is a suitable choice for sports complex construction projects due to its strength, flexibility, and ability to create complex structures efficiently.

- Q: How does steel formwork handle concrete pouring in cold weather?

- Steel formwork is a preferred choice for concrete pouring in cold weather due to its durability and ability to withstand extreme temperatures. It acts as a protective barrier against freezing temperatures, preventing the concrete from freezing too quickly, which could lead to weakened structures. The steel formwork also helps to retain heat generated during the concrete curing process, ensuring proper and consistent curing even in colder conditions.

- Q: Can steel formwork be used for both single-use and multi-use applications?

- The utilization of steel formwork can cater to both single-use and multi-use purposes. The decision between these two options heavily relies on the particular demands of the construction project and the allocated budget for formwork. When it comes to single-use applications, steel formwork can be easily customized and manufactured to fit the specific dimensions and shapes necessary for the concrete structure. Once the concrete has solidified, the formwork can be taken off and discarded. This proves to be a cost-effective approach for projects that do not require the formwork for future use. On the flip side, steel formwork can also be designed and produced for multi-use purposes. In this scenario, the formwork is constructed to be sturdy and capable of being reused in multiple construction projects. Steel formwork boasts a longer lifespan compared to materials like timber, making it suitable for repeated use. Moreover, steel formwork can be effortlessly adjusted and reconfigured to accommodate various shapes and sizes, further enhancing its versatility. Nevertheless, it is crucial to note that proper maintenance and care are necessary to ensure the longevity and structural integrity of multi-use steel formwork. Regular inspection, cleaning, and repair of the formwork are essential to prevent any potential issues that may arise from repeated use. To summarize, steel formwork can be employed for both single-use and multi-use purposes, depending on the specific requirements and budget of the construction project. While single-use formwork offers a cost-effective solution, multi-use formwork provides durability and versatility for repeated use.

- Q: How does steel formwork affect the overall durability of a structure?

- The durability of a structure can be greatly influenced by steel formwork. Steel formwork is known for its strength and durability, which provides excellent support and stability during the construction process. This ensures accurate construction according to required specifications, which is vital for long-term durability. Using steel formwork offers several advantages. It has the ability to withstand high pressures and loads, which is especially important in large-scale construction projects involving heavy concrete pours. The steel formwork effectively distributes the weight and pressure exerted by the concrete, preventing any deformation or collapse. This helps maintain the structure's integrity and durability over time. In addition, steel formwork is highly resistant to environmental factors such as moisture, humidity, and temperature changes. This resistance protects the structure from potential damage such as corrosion, rot, or warping, enhancing its overall durability. This reduces the need for expensive repairs or maintenance. Furthermore, steel formwork provides a smooth and even surface for the concrete to adhere to during the curing process. This results in a uniform and consistent finish, reducing the risk of cracks or weak points in the structure. This absence of defects improves the structure's durability, as it is less prone to structural weaknesses that can compromise its integrity over time. Moreover, steel formwork is reusable and can be easily dismantled and reassembled for multiple construction projects. This not only reduces construction costs but also minimizes waste and environmental impact. The ability to reuse steel formwork ensures consistent use of high-quality materials, contributing to the structure's long-term durability. In conclusion, steel formwork plays a significant role in determining the overall durability of a structure. Its strength, resistance to environmental factors, ability to distribute loads, and provision of a uniform finish all contribute to the long-term durability and structural integrity of the building. By utilizing steel formwork, builders can ensure that the structure is built to last, minimizing the need for future repairs or replacements.

Send your message to us

Auto-climbing bracket ACB-100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches