Auto-Climbing bracket ACB 100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

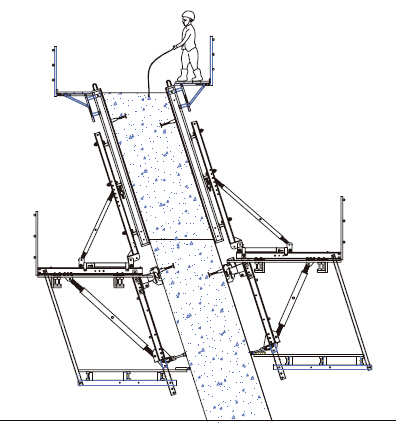

Auto-climbing Bracket ACB100 & ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q:What are the different types of connections used in steel formwork?

- There are several types of connections used in steel formwork, including bolted connections, welded connections, and clamped connections. Bolted connections involve using bolts and nuts to secure the formwork together, ensuring a strong and secure connection. Welded connections involve welding the steel plates or components together, creating a permanent and durable connection. Clamped connections use clamps to hold the formwork in place, providing a quick and adjustable connection method. Each type of connection has its advantages and is chosen based on the specific requirements of the project.

- Q:Types of building templates? What is the clear water template

- 2 steel template: in addition to the combination of steel templates, has developed a wide steel template, all steel large formwork, light large steel mold, steel frame, such as 63 steel template. The high cost of steel mold, in addition to large projects such as bridges or other buildings, nuclear power plants, reservoirs and other construction sites, has been replaced by building wooden template.

- Q:How does steel formwork accommodate for different concrete curing methods?

- Steel formwork is a versatile construction material that can accommodate different concrete curing methods due to its durability, flexibility, and ease of use. Firstly, steel formwork allows for various curing methods such as wet curing, dry curing, and accelerated curing. Wet curing involves keeping the concrete moist and hydrated for a specific period, while dry curing involves keeping the concrete in a controlled environment with low humidity. Accelerated curing, on the other hand, utilizes external heat sources to expedite the curing process. Steel formwork is well-suited for wet curing as it can effectively retain moisture and prevent water loss from the concrete. The steel panels are tightly fitted together, forming a watertight enclosure that minimizes evaporation. This ensures that the concrete remains adequately hydrated during the curing process, promoting proper strength development and minimizing the risk of cracking or shrinkage. Similarly, steel formwork can easily accommodate dry curing methods. The steel panels provide a barrier between the concrete and the surrounding environment, allowing for precise control of humidity levels. This is especially beneficial in hot or dry climates, where maintaining a low humidity environment is crucial for preventing premature moisture loss and ensuring proper curing. Additionally, steel formwork is compatible with accelerated curing techniques. Its ability to withstand high temperatures makes it suitable for applications where external heat sources are used to expedite the curing process. The steel panels can withstand the elevated temperatures without warping or compromising their structural integrity. Moreover, steel formwork can be easily adjusted or modified to accommodate specific curing requirements. The modular nature of steel formwork allows for flexibility in design and construction. By simply rearranging or adding steel panels, the formwork can be customized to create different shapes, sizes, or configurations, which is particularly useful when dealing with complex or unique concrete structures. Overall, steel formwork is a reliable choice for accommodating different concrete curing methods. Its durability, flexibility, and adaptability make it a preferred option in construction projects that require precise control over the curing process to achieve optimal concrete strength and quality.

- Q:Can steel formwork be easily repaired in case of damage?

- Yes, steel formwork can be easily repaired in case of damage. Steel is a durable and malleable material, allowing for straightforward repairs such as welding, patching, or replacing damaged sections. Additionally, its strength and resilience make it less prone to damage compared to other formwork materials like wood or plastic.

- Q:How does steel formwork contribute to the overall speed of construction?

- Steel formwork contributes to the overall speed of construction by providing a durable and reusable solution for creating concrete structures. The use of steel formwork allows for faster and more efficient construction processes as it can be easily assembled and disassembled, reducing the time required for formwork installation and removal. Additionally, steel formwork provides a smooth and consistent surface, resulting in faster curing times and improved productivity.

- Q:How does steel formwork contribute to the overall durability of a structure?

- There are several ways in which steel formwork enhances the overall durability of a structure. Firstly, its resistance to wear and tear allows it to withstand the heavy loads and pressures exerted during construction, preventing any deformations or damages. This ensures accurate construction and maintains the structure's integrity. Furthermore, steel formwork exhibits excellent dimensional stability, retaining its shape and size even under extreme conditions like high temperatures or moisture exposure. This stability ensures that the concrete poured into the formwork maintains its desired shape and structural strength, resulting in a more durable structure. Additionally, steel formwork offers superior strength and rigidity compared to other materials. This strength allows it to support heavy concrete loads without any deformation or collapse, ensuring the stability and security of the structure. This is particularly important for large-scale structures such as bridges or high-rise buildings, where the formwork must bear significant loads for extended periods. Moreover, steel formwork is highly resistant to corrosion, a common cause of deterioration in construction materials. This resistance protects the formwork from environmental factors like moisture or chemicals, enhancing the structure's overall durability by minimizing the risk of corrosion-related damages. Lastly, the reusability of steel formwork contributes to both the sustainability of the construction process and cost-effectiveness. By being able to reuse the formwork multiple times, the need for additional materials and resources is reduced, resulting in less waste and lower construction costs. Additionally, the ability to properly maintain and inspect the formwork before each reuse enhances its durability and longevity. In conclusion, steel formwork is crucial in enhancing the overall durability of a structure. Its resistance to wear and tear, dimensional stability, strength, corrosion resistance, and reusability all contribute to the construction of a strong and long-lasting structure, ensuring its integrity and minimizing the risk of structural failures or damages over time.

- Q:Are there any specific design considerations for steel formwork?

- Yes, there are specific design considerations for steel formwork. These include factors such as the strength and stability of the steel structure, the weight-bearing capacity of the formwork, ease of assembly and disassembly, compatibility with different concrete mixtures, and the ability to withstand various site conditions such as weather and construction loads. Additionally, the design should also consider the reusability and durability of the steel formwork system to ensure cost-effectiveness and sustainability in construction projects.

- Q:Can steel formwork be used for precast concrete beams with complex geometries?

- Yes, steel formwork can be used for precast concrete beams with complex geometries. Steel formwork provides high strength and flexibility, allowing it to be easily shaped and adjusted to meet the specific geometrical requirements of the precast concrete beams. This makes it a suitable choice for creating complex and intricate shapes during the precast concrete beam manufacturing process.

- Q:How does steel formwork handle different concrete surface slip resistance?

- Steel formwork is a versatile and strong material that is commonly used in construction projects to shape and support concrete during the curing process. When it comes to handling different concrete surface slip resistance, steel formwork offers several advantages. Firstly, steel formwork provides a smooth and even surface for pouring concrete, which helps to minimize variations in slip resistance. Unlike other materials such as wood, steel does not warp or deform, ensuring consistent contact between the formwork and the concrete. This uniformity in contact helps to create a more consistent concrete surface, reducing the chances of uneven slip resistance. Additionally, steel formwork allows for the use of various surface treatments and coatings that can enhance slip resistance. For instance, anti-slip coatings or aggregates can be added to the formwork surface before pouring the concrete, creating a textured surface that improves traction. These treatments can be customized to meet specific slip resistance requirements, allowing for flexibility in design. Moreover, steel formwork is highly durable and resistant to wear and tear. This durability ensures that the formwork maintains its structural integrity throughout the concrete pouring process, minimizing the chances of surface irregularities that could affect slip resistance. Furthermore, steel formwork can be easily cleaned and maintained, ensuring that any contaminants or debris that could affect slip resistance are promptly addressed. In summary, steel formwork is able to handle different concrete surface slip resistance by providing a smooth and consistent surface, allowing for customization through various surface treatments, and maintaining durability to prevent surface irregularities. Its strength and versatility make steel formwork a reliable choice for construction projects where slip resistance is a concern.

- Q:Can steel formwork be used for both single-storey and multi-storey structures?

- Yes, steel formwork can be used for both single-storey and multi-storey structures. The versatility and strength of steel make it suitable for various construction projects, regardless of the number of storeys in the building. Steel formwork offers durability, easy assembly, and reusability, making it a popular choice for both small and large-scale construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto-Climbing bracket ACB 100 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches