Auto-Climbing bracket ACB100 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

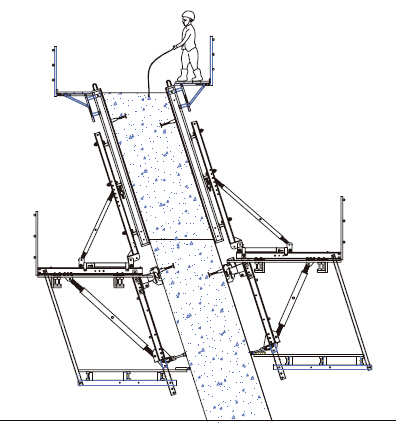

Auto-climbing Bracket ACB100 & ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q: How does steel formwork affect the overall structural integrity of a building?

- The overall structural integrity of a building is heavily reliant on steel formwork. During the construction process, steel formwork is used as a temporary mold or framework to shape and support concrete until it hardens and gains enough strength to bear its own weight and other applied loads. One of the main benefits of steel formwork is its superior strength and durability in comparison to other types of formwork like wood or plastic. Steel possesses high tensile strength and resistance to deformation, enabling it to withstand the pressure exerted by wet concrete without significant distortion. This strength ensures that the formwork maintains its shape and stability throughout the pouring and curing of concrete, preventing any potential collapse or failure that could compromise the building's structural integrity. Moreover, the use of steel formwork delivers precise and accurate results in terms of dimension and shape, which is crucial for achieving the desired structural integrity. Steel formwork can be fabricated to exact specifications, allowing for tight tolerances and precise positioning of reinforcement, resulting in a more uniform and robust structure. This precision guarantees that the building can endure various external loads, such as wind, seismic forces, and live loads, without excessive deflection or deformation. Additionally, steel formwork offers excellent reusability, making it a cost-effective and sustainable choice for construction projects. Unlike other formwork types that may require frequent replacement, steel formwork can be used multiple times, reducing material waste and overall project costs. This reusability also contributes to the building's structural integrity, as the formwork is less prone to deterioration or degradation over time, ensuring consistent quality and performance. To summarize, steel formwork significantly enhances the overall structural integrity of a building by providing superior strength, precision, and durability. Its ability to withstand the pressure of wet concrete, maintain accurate dimensions, and resist external loads ensures the building's structural stability and safety. Furthermore, the reusability of steel formwork offers cost-effective and sustainable advantages, further contributing to the long-term structural integrity of the constructed building.

- Q: How does steel formwork handle concrete pouring and consolidation?

- Steel formwork is a popular choice for concrete pouring and consolidation due to its strength, durability, and ease of use. When it comes to handling concrete pouring and consolidation, steel formwork offers several advantages. Firstly, steel formwork provides a solid and rigid structure that can withstand the pressure exerted by the weight of the concrete. This ensures that the formwork remains stable throughout the pouring and consolidation process, preventing any deformations or collapses that could compromise the quality of the concrete structure. Additionally, steel formwork is highly resistant to moisture and chemicals present in the concrete mix, which helps to maintain its integrity and durability. This resistance ensures that the formwork does not get damaged or corroded during the pouring and consolidation process, thereby prolonging its lifespan and reducing maintenance costs. Moreover, steel formwork allows for efficient and precise concrete placement and consolidation. The smooth surfaces of steel formwork facilitate the easy flow and distribution of the concrete, ensuring that it fills all the required areas evenly. This helps to eliminate voids and air pockets, resulting in a denser and more structurally sound concrete structure. Furthermore, steel formwork can be easily adjusted and customized to meet specific project requirements. Its modular nature allows for easy assembly and disassembly, making it a cost-effective choice for various construction projects. The flexibility of steel formwork also allows for the creation of complex shapes and designs, enabling architects and engineers to realize their creative visions. In conclusion, steel formwork is an ideal choice for handling concrete pouring and consolidation due to its strength, durability, and versatility. It provides a stable and robust structure that can withstand the weight and pressure of the concrete, while also ensuring efficient and precise placement and consolidation. These qualities make steel formwork a reliable and practical solution for a wide range of construction projects.

- Q: What are some of the components of the combined steel template, what role?

- Two, the main equipment1, mechanical equipment, drill, grinding wheel cutting machine, according to the circular machine, electric wrenches and welding equipment, etc..2, the main tool hammer, iron ruler, steel ruler, wrench, wire brush, brush. Drums, crowbar, screwdriver, theodolite, level. Tower ruler.

- Q: Is steel formwork suitable for projects with high concrete pressure?

- Indeed, steel formwork proves to be a suitable choice for projects that involve high concrete pressure. Renowned for its robustness and durability, steel formwork possesses the ability to withstand the immense pressure exerted by the wet concrete during both pouring and curing stages. It effectively bears the weight and pressure of the concrete, preventing any deformation or collapse, thus ensuring the structure's stability and integrity throughout the construction process. Furthermore, steel formwork guarantees a smooth and uniform surface finish for the concrete, which is crucial for projects that demand top-notch quality. Moreover, its reusability feature makes it a cost-effective option for projects that entail high concrete pressure.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork helps to handle concrete bleeding and segregation in several ways. Firstly, the smooth and impermeable surface of steel formwork prevents excessive bleeding of water from the concrete mix. This helps in maintaining the desired water-cement ratio, which is essential for the strength and durability of the concrete. Secondly, steel formwork provides a rigid structure that holds the concrete in place, reducing the chances of segregation. It prevents the coarse aggregates from settling at the bottom, ensuring a uniform distribution of aggregates and cement throughout the concrete. Additionally, steel formwork systems are designed with proper reinforcement and bracing, which further minimizes the risk of concrete segregation during the pouring and curing process. The rigid construction of steel formwork also helps in preventing any movement or displacement of the concrete, which can lead to segregation. Overall, steel formwork is an effective solution for handling concrete bleeding and segregation by providing a stable and impermeable surface, proper reinforcement, and preventing any movement or displacement of the concrete.

- Q: How does steel formwork handle different concrete reinforcement spacing?

- Steel formwork is able to handle different concrete reinforcement spacing by providing flexibility and adaptability in its design. The formwork is typically adjustable, allowing for the necessary spacing between reinforcement bars to be accommodated. This ensures that the concrete is poured and compacted around the reinforcement bars evenly, maintaining structural integrity and strength. Additionally, steel formwork is durable and strong, capable of withstanding the pressures exerted by the concrete and the reinforcement bars, regardless of their spacing.

- Q: Can steel formwork be used for structures with high wind resistance requirements?

- Yes, steel formwork can be used for structures with high wind resistance requirements. Steel is a strong and durable material that can withstand the forces exerted by high winds. When used as formwork, steel provides a stable and rigid framework for pouring concrete, ensuring that the structure maintains its shape and integrity even under extreme wind conditions. Additionally, steel formwork can be designed and reinforced to meet specific wind load requirements, making it suitable for constructing buildings in areas prone to high winds or hurricanes.

- Q: Can steel formwork be used in high-rise construction projects?

- Yes, steel formwork can be used in high-rise construction projects. Steel formwork offers several advantages such as durability, strength, and the ability to withstand high concrete pressure. It provides a stable and efficient solution for constructing walls, slabs, and columns in high-rise buildings. Additionally, steel formwork can be easily customized and reused, making it a cost-effective choice for such projects.

- Q: Can steel formwork be used in industrial construction projects?

- Yes, steel formwork can definitely be used in industrial construction projects. Steel formwork is known for its strength, durability, and high load-carrying capacity, making it suitable for heavy-duty applications like industrial construction. It can withstand the pressure exerted by large concrete pours and can be reused multiple times, making it a cost-effective choice for large-scale projects. Steel formwork also provides a smooth and uniform finish to the concrete structure, ensuring high-quality results. Additionally, steel formwork offers flexibility in terms of design and can be customized to meet the specific requirements of industrial construction projects. Overall, steel formwork is a reliable and efficient solution for industrial construction projects.

- Q: Can steel formwork be used for power plant construction projects?

- Indeed, power plant construction projects can utilize steel formwork. Steel formwork proves to be an adaptable and long-lasting option for crafting concrete structures across diverse sectors, including power plant construction. It presents numerous benefits, such as exceptional strength, effortless assembly and disassembly, as well as the capability to endure substantial loads and harsh weather conditions. Moreover, steel formwork can be tailored to meet the distinctive needs of power plant construction, facilitating the production of intricate and accurate concrete components. Furthermore, steel formwork can be repeatedly utilized, thereby offering a cost-efficient and environmentally-friendly alternative for power plant projects.

Send your message to us

Auto-Climbing bracket ACB100 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches