Austenitic stainless steel plate304 304L 316 316L 309S 310S 321 347H 317L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Item: Austenitic stainless steel plate

Grade: 304, 304L, 316, 316L, 317L, 347H, 309S, 310S, 321...

New & Fresh Stocks!!!

Best & Lowest price!!!

Thickness: 0.3mm / 0.5mm / 0.8mm / 1.0mm / 1.5mm / 2.0mm / 2.5mm / 3.0mm / 4-110mm

Width: 1000mm, 1220mm(1219mm). 1250mm, 1500mm, 1524mm, 1800mm, 2000mm

Length: 2000mm, 2440mm(2438mm), 3000mm, 6000mm, special size can be customized

Product Uses

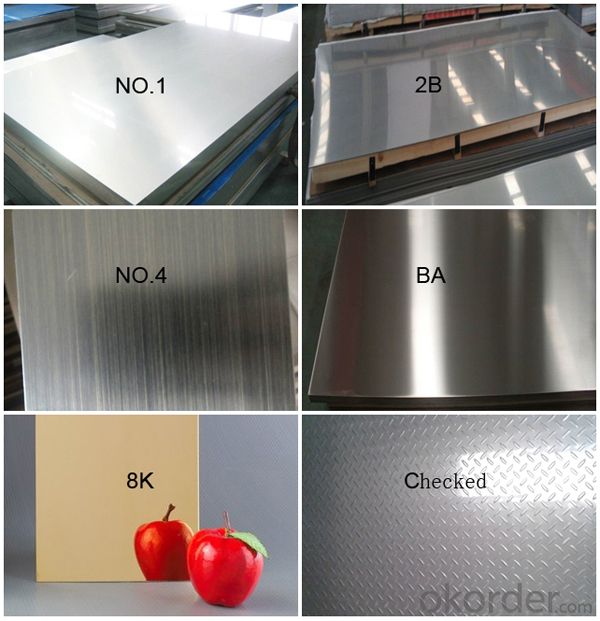

Finish | Thickness | Characteristics |

No. 1 | 2.0mm ~12.0mm | Surface finished by hot-rolling, annealing and pickling, characterized by white pickled surface. |

2B | 0.3mm ~3.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be brighter. |

BA | 0.3mm ~1.5mm | Processed with bright heat treatment after cold rolling. |

No. 4 | 0.4mm ~3.0mm | Polishing with No. 150 to No.180 abrasives. The most popular finishes. |

HL | 0.4mm ~3.0mm | Finished by continuous polishing streaks by using abrasive of suitable grain size. |

SB | 0.4mm ~3.0mm | Polishing with No. 150 to No. 180 Scotch-Brite abrasives. |

Packaging & Shipping

- Q: How do you prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to avoid exposure to corrosive substances such as chloride-based cleaners or acids. Regular cleaning using mild, non-abrasive cleaners and soft cloths is recommended. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or saltwater environments can help prevent pitting. Regular inspections and prompt repairs of any scratches or damages can also contribute to maintaining the integrity of stainless steel sheets and preventing pitting.

- Q: What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary based on the specific grade and manufacturing process employed. Typically, stainless steel sheets are renowned for their exceptional hardness and strength. In industrial applications, the most commonly utilized grades, such as 304 and 316, exhibit a hardness range of 70-90 HRB (Rockwell hardness B scale) or 150-200 HV (Vickers hardness). However, there are also specialized stainless steel alloys available that can possess even higher degrees of hardness, such as precipitation-hardened grades like 17-4 PH, which can attain hardness levels of 30-40 HRC (Rockwell hardness C scale). To determine the precise hardness of a particular stainless steel sheet, reference to the manufacturer's specifications or performing hardness testing utilizing appropriate methods and equipment is necessary.

- Q: What is 3042B stainless steel?

- 304: general model, that is, 18/8 stainless steel. Products such as: corrosion-resistant containers, tableware, furniture, railings, medical equipment. The standard ingredient is 18% chromium plus 8% nickel. Stainless steel that is free of magnetism and can not be altered by heat treatment. GB is 0Cr18Ni9.

- Q: Are stainless steel sheets resistant to impact?

- Yes, stainless steel sheets are generally resistant to impact. Stainless steel is known for its high strength and durability, which allows it to withstand significant force without deforming or breaking. This makes stainless steel sheets a popular choice for applications that require resistance to impact, such as in construction, automotive, and aerospace industries. Additionally, stainless steel sheets can be further hardened or tempered to enhance their impact resistance, depending on the specific requirements of the application.

- Q: Are stainless steel sheets safe for contact with food?

- Yes, stainless steel sheets are safe for contact with food. Stainless steel is a widely used material in the food industry due to its non-reactive and corrosion-resistant properties. It does not leach harmful chemicals or flavors into food, making it a safe choice for food preparation and storage. Additionally, stainless steel is easy to clean and maintain, minimizing the risk of bacterial growth. However, it is important to note that not all stainless steel is created equal, and it is recommended to choose food-grade stainless steel that meets specific standards for food contact.

- Q: Are stainless steel sheets resistant to crevice corrosion?

- Stainless steel sheets generally possess resistance to crevice corrosion, which occurs in confined spaces like gaps or crevices between surfaces, where limited oxygen and other corrosive agents exist. These sheets are primarily composed of iron, chromium, and other alloying elements that generate a protective oxide layer on their surface, effectively preventing the infiltration of corrosive agents. This oxide layer acts as a barrier, endowing stainless steel with high resistance against crevice corrosion. However, it's worth noting that the degree of resistance can vary based on the specific grade and composition of the stainless steel, as well as the environmental conditions it encounters.

- Q: Can stainless steel sheets be used for architectural façades?

- Architectural façades can indeed incorporate stainless steel sheets. With their durability and versatility, stainless steel proves to be an advantageous material for such applications. Its resistance to corrosion, weathering, and staining makes it perfect for outdoor use. Moreover, stainless steel sheets can be manipulated into various shapes and sizes, allowing for a wide array of design possibilities. Furthermore, stainless steel can be finished in diverse ways, including brushing, polishing, or coloring, which adds further aesthetic options. Its strength and rigidity also make it suitable for large installations. All in all, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a highly sought-after choice for architectural façades.

- Q: Can stainless steel sheets be used in medical equipment?

- Medical equipment can indeed make use of stainless steel sheets. Due to its exceptional properties like resistance to corrosion, durability, and ease of cleaning, stainless steel is a favored option for medical devices and equipment. It is frequently employed in surgical instruments, implants, hospital equipment, and laboratory tools. The versatility of stainless steel sheets makes them a common choice in the manufacturing of medical equipment as they can be shaped into various forms and sizes. Furthermore, stainless steel is highly biocompatible, meaning it poses no harm to bodily tissues and can be safely used in medical applications. All in all, stainless steel sheets are a dependable and widely accepted material for medical equipment, offering both hygienic qualities and long-lasting performance.

- Q: Can stainless steel sheets be used for medical implant devices?

- Medical implant devices can utilize stainless steel sheets, as they possess excellent mechanical properties, corrosion resistance, and biocompatibility. Stainless steel is widely employed in the medical field due to its strength, durability, and ability to endure sterilization processes. Various medical implant devices, including plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and other procedures, can be fabricated from stainless steel sheets. The high strength-to-weight ratio of stainless steel makes it suitable for applications requiring load-bearing capabilities, while its resistance to corrosion ensures longevity within the body. Moreover, stainless steel is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions or allergies. Techniques like passivation or coating can enhance the biocompatibility of stainless steel surfaces. It is vital to emphasize that selecting the appropriate stainless steel grade and surface finish is essential for medical implant devices to ensure compatibility with specific body tissues and environments. Thorough testing and regulatory approval are also necessary to guarantee the safety and effectiveness of stainless steel medical implant devices. To summarize, stainless steel sheets can indeed be utilized for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Ensuring the suitability and safety of stainless steel implants in medical applications necessitates proper selection, testing, and regulatory approval.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Yes, stainless steel sheets can be used for medical instrument trays. Stainless steel is a commonly used material in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. Medical instrument trays are used to store and organize various medical instruments during procedures. Stainless steel sheets are ideal for this purpose as they are non-reactive and can withstand frequent sterilization processes such as autoclaving. Additionally, stainless steel has a smooth surface that is resistant to scratches and dents, ensuring the trays remain hygienic and easy to clean. Overall, stainless steel sheets are a reliable and suitable material choice for medical instrument trays.

Send your message to us

Austenitic stainless steel plate304 304L 316 316L 309S 310S 321 347H 317L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords