Embossed Aluminum Sheets as per American Standard ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Auminium Sheet As Per American Standard ASTM Description

Auminium Sheet As Per American Standard ASTM is semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Auminium Sheet As Per American Standard ASTM

Auminium Sheet As Per American Standard ASTM | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Auminium Sheet As Per American Standard ASTM

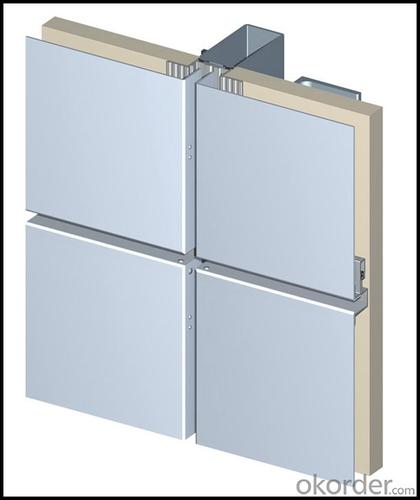

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Auminium Sheet As Per American Standard ASTM

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Auminium Sheet As Per American Standard ASTM

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Auminium Sheet As Per American Standard ASTM

7. Package and shipping of Auminium Sheet As Per American Standard ASTM

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for signs or methods to identify if a building is utilizing aluminum sheets in its construction or design.

- <p>To determine if a building is using aluminum sheets, look for the following signs: 1) Shiny, metallic appearance, which is characteristic of aluminum. 2) Lightweight construction, as aluminum is less dense than many other metals. 3) Resistance to corrosion and weathering, a common feature of aluminum. 4) Use in areas prone to water or moisture, as aluminum is water-resistant. 5) Check for the manufacturer's specifications or building materials list. If possible, consult with the building's architect or engineer for confirmation.</p>

- Q: What are the different methods of joining aluminum sheets?

- Aluminum sheets can be joined using a variety of methods, each with its own benefits and suitability for specific applications. These methods include: 1. Welding: Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW) are all techniques that can be used to join aluminum sheets. TIG welding is commonly chosen for thin sheets due to its precise control and high-quality results. MIG welding, on the other hand, is faster and more suitable for thicker sheets. RSW creates strong welds in a short amount of time by using localized heat and pressure. 2. Adhesive bonding: Adhesive bonding involves using specially designed adhesives for joining aluminum. This method provides excellent strength, even distribution of stress, and corrosion resistance. It is often utilized in applications where aesthetics and weight reduction are important, such as in the automotive and aerospace industries. 3. Mechanical fastening: Mechanical fastening methods, such as riveting and bolting, can also be used to join aluminum sheets. Riveting involves deforming a rivet that passes through pre-drilled holes, while bolting uses screws or bolts. These methods are suitable for temporary or semi-permanent joints and offer easy disassembly if needed. 4. Friction stir welding: Friction stir welding is an innovative method that utilizes a rotating tool to generate frictional heat between the aluminum sheets. This creates a plasticized region that is stirred together to form a solid-state weld. Friction stir welding is particularly useful for large and complex aluminum structures, providing high strength and integrity. 5. Clinching: Clinching is a cold-forming process that joins aluminum sheets without the need for heat or additional materials. It involves pressing the sheets together, creating a mechanical interlock and a strong joint. This method is cost-effective, efficient, and suitable for joining dissimilar metals. 6. Laser welding: Laser welding involves using a high-energy laser beam to melt and fuse the aluminum sheets together. It offers precise control, minimal heat input, and high welding speeds, making it suitable for thin and delicate sheets. Laser welding also provides excellent aesthetics and minimal distortion. The choice of joining method depends on various factors, such as application requirements, material thickness, cost considerations, and desired joint strength. Each method has its own advantages and limitations, and selecting the most appropriate method is crucial to ensure a successful and durable joint.

- Q: Can 101 aluminum sheets be powder coated?

- Indeed, powder coating is a highly adaptable and long-lasting method of finishing that can be utilized on a multitude of substances, aluminum included. This procedure entails the application of a dry powder onto the surface of the aluminum sheets, subsequently subjecting it to heat and fusion in order to generate a sleek and resilient coating. The extensive assortment of colors and finishes offered by powder coating renders it a perfect option for both enhancing the visual appeal and safeguarding the aluminum sheets.

- Q: Can aluminum sheets be laser engraved?

- Yes, aluminum sheets can be laser engraved.

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability, making them ideal for various applications in industries such as construction, automotive, and aerospace.

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- aluminium wiring was very common in the '70's. there is nothing wrong with this wiring. it would be a lot better to have copper, but in your situation it is ok. to replace the wiring would be very labour intensive, and expensive. they likely wouldn't remove the whole wall and would do most of thee work in the basement and attic, if u have one. rewiring a house is like doing brain surgery in the dark. it is very important, though that u remember if u have any repairs, (ie: changing a recepticle, a switch, or breaker) you use aluminum compatible parts.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

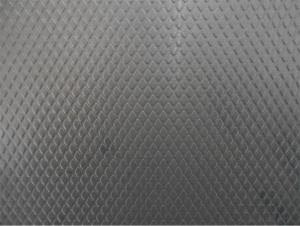

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

Send your message to us

Embossed Aluminum Sheets as per American Standard ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords