ASTM A484 Standard 304 Stainless Steel Round Bar Polished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM A484 Standard 304 Stainless Steel Round Bar Polished

Details of StainASTM A484 Standard 304 Stainless Steel Round Bar Polished

Name | Stainless Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

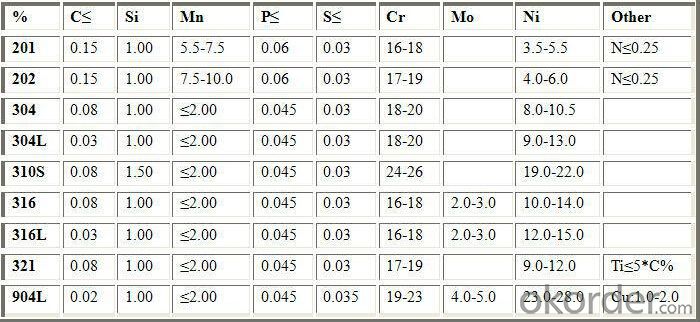

Specification of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

CNBM Introduction of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

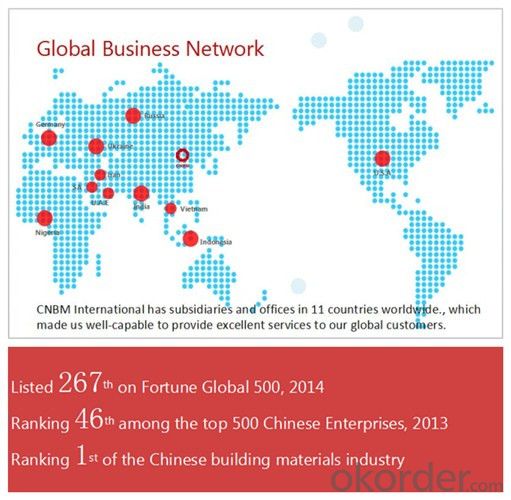

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to improving product safety in high-risk industries?

- Special steel plays a crucial role in improving product safety in high-risk industries due to its unique properties and characteristics. Its exceptional strength, durability, and resistance to corrosion make it highly reliable and less prone to failure under extreme conditions. By using special steel in the manufacturing of critical components and structures, such as in aerospace, automotive, and oil and gas industries, it ensures enhanced safety and prevents potential accidents or catastrophic failures. Additionally, the strict quality control and certifications associated with special steel guarantee that it meets the industry's stringent safety standards, providing peace of mind to both manufacturers and end-users.

- Q: What are the main characteristics of high-speed steel?

- High-speed steel (HSS) possesses exceptional properties that make it widely used in machining applications. HSS is characterized by its superior hardness, achieved through the addition of alloying elements such as tungsten, molybdenum, cobalt, vanadium, and chromium. This hardness allows HSS to withstand high temperatures and resist wear. Another notable characteristic of high-speed steel is its excellent heat resistance, enabling it to maintain its hardness and strength even at elevated temperatures. This is crucial in applications where the tool needs to endure high cutting speeds and generate significant amounts of heat. HSS also demonstrates good toughness, resisting cracking and chipping under heavy loads or impact. This ensures the tool's ability to withstand demanding cutting conditions without premature failure. Furthermore, high-speed steel exhibits high wear resistance, making it suitable for cutting, drilling, and milling operations. It retains its sharpness and performance even with prolonged usage, resulting in extended tool life. High-speed steel is highly versatile and can be used for cutting, shaping, and forming various materials such as metals, plastics, and wood. Its versatility makes it a popular choice in industries like manufacturing, automotive, aerospace, and construction. Additionally, HSS can be easily machined and shaped into different tool designs, allowing for customization and optimization based on specific applications. This makes it a preferred material for manufacturing cutting tools like drills, end mills, taps, and saw blades. Compared to other high-performance tool materials like carbide, high-speed steel is relatively more cost-effective. It strikes a balance between performance and affordability, making it a cost-efficient choice for many machining applications. In conclusion, high-speed steel is highly valued for its exceptional hardness, heat resistance, toughness, wear resistance, versatility, ease of machining, and cost-effectiveness. These characteristics make it a preferred material for a wide range of cutting tools, ensuring efficient and reliable machining operations.

- Q: What are the different classifications of special steel?

- There are several classifications of special steel, including stainless steel, tool steel, high-speed steel, alloy steel, and carbon steel.

- Q: What are the different forming techniques used for special steel?

- Some of the different forming techniques used for special steel include hot forging, cold forging, extrusion, rolling, and casting.

- Q: What are the different heat treatment processes for special steel?

- There are several heat treatment processes for special steel, including annealing, quenching, tempering, and normalizing. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to enhance its ductility and reduce internal stresses. Quenching is a rapid cooling process that involves immersing the steel in a liquid, such as water or oil, to increase its hardness and strength. Tempering is a process that follows quenching, where the steel is heated to a lower temperature and then cooled, which helps to relieve internal stresses and improve toughness. Normalizing is a process similar to annealing, but the steel is air-cooled instead of being slowly cooled, resulting in a more refined grain structure and improved mechanical properties.

- Q: How does special steel contribute to the oil and gas aftermarket industry?

- Special steel plays a crucial role in the oil and gas aftermarket industry due to its unique properties and capabilities. Firstly, special steel is highly resistant to corrosion, making it ideal for use in the harsh and corrosive environments commonly found in the oil and gas sector. This resistance to corrosion ensures that the equipment and components made from special steel have a longer lifespan, reducing the need for frequent replacements and maintenance. Additionally, special steel offers high strength and durability, allowing it to withstand the extreme pressures and temperatures encountered in oil and gas operations. This strength ensures that the equipment and components made from special steel can operate reliably and efficiently, even under demanding conditions. Moreover, special steel can be tailored to meet the specific needs of the oil and gas industry. With its various grades and compositions, special steel can be customized to possess specific properties such as resistance to sulfide stress cracking, hydrogen embrittlement, and high-temperature oxidation. These customized properties make special steel suitable for critical applications such as wellheads, pipelines, valves, and other equipment used in the oil and gas aftermarket industry. Furthermore, special steel enables the production of complex and intricate components that are essential for the oil and gas sector. Its excellent machinability and weldability allow for the creation of precision-engineered parts, ensuring the efficient and reliable operation of oil and gas equipment. In summary, special steel contributes significantly to the oil and gas aftermarket industry by providing corrosion resistance, high strength, durability, customization options, and the ability to manufacture intricate components. These properties make special steel indispensable in ensuring the safety, reliability, and efficiency of operations in the oil and gas sector.

- Q: How does special steel contribute to the manufacturing of springs?

- Special steel plays a crucial role in the manufacturing of springs due to its unique properties and characteristics. Springs are mechanical components that store and release mechanical energy, and special steel provides the necessary strength, durability, and resilience for these applications. One of the key contributions of special steel to spring manufacturing is its high tensile strength. Special steel alloys are designed to have a higher strength-to-weight ratio compared to regular steels, allowing springs to withstand heavy loads and high stresses without deforming or breaking. This property ensures the longevity and reliability of springs, even in demanding applications such as automotive suspensions or industrial machinery. Furthermore, special steel exhibits excellent elasticity and resilience. Springs need to retain their shape and performance over repeated cycles of compression and extension. Special steel alloys are formulated to have a high elastic limit, meaning they can be deformed significantly and still return to their original shape without permanent deformation. This property allows springs to absorb and release energy reliably, providing the desired mechanical functionality in various applications. Another important contribution of special steel to spring manufacturing is its resistance to fatigue and corrosion. Springs are often subjected to cyclic loading, which can lead to fatigue failure over time. Special steel alloys are designed to have enhanced fatigue resistance, allowing springs to endure millions of cycles without failure. Additionally, special steel can be further treated or coated to enhance its corrosion resistance, which is crucial for springs exposed to harsh environments or chemicals. In conclusion, special steel significantly contributes to the manufacturing of springs by providing high tensile strength, excellent elasticity and resilience, fatigue resistance, and corrosion resistance. These properties ensure the durability, performance, and longevity of springs, making them essential components in various industries such as automotive, aerospace, and manufacturing.

- Q: What are the requirements for special steel used in corrosive environments?

- The requirements for special steel used in corrosive environments include high resistance to corrosion, especially against specific corrosive agents such as acids, alkalis, or saline solutions. The steel should possess a strong passive film formation ability, preventing further corrosion. It should also have good mechanical properties, including high strength and toughness, to withstand the harsh conditions. Additionally, the steel must possess good welding and fabrication characteristics, as well as be cost-effective and readily available.

- Q: What are the applications of special steel in aerospace engineering?

- Special steel is widely used in aerospace engineering for various applications. It is used to manufacture critical components such as turbine blades, landing gear, and structural parts that require high strength, toughness, and resistance to extreme temperatures. Special steel alloys, such as stainless steel and nickel-based alloys, are used due to their excellent corrosion resistance, heat resistance, and ability to withstand harsh environments. These materials ensure the safety and reliability of aircraft, enabling them to operate under demanding conditions and meet stringent performance requirements.

- Q: How is magnetic alloy steel used in the production of magnetic components?

- Magnetic alloy steel is used in the production of magnetic components due to its high magnetic permeability and excellent magnetic properties. It is commonly utilized in manufacturing various magnetic components such as cores, stators, rotors, and transformers. The alloy's magnetic properties allow for efficient magnetization and demagnetization, making it suitable for applications where strong magnetic fields are required. Additionally, magnetic alloy steel is often used in electrical motors, generators, and magnetic sensors, contributing to their overall performance and reliability.

Send your message to us

ASTM A484 Standard 304 Stainless Steel Round Bar Polished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords