1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

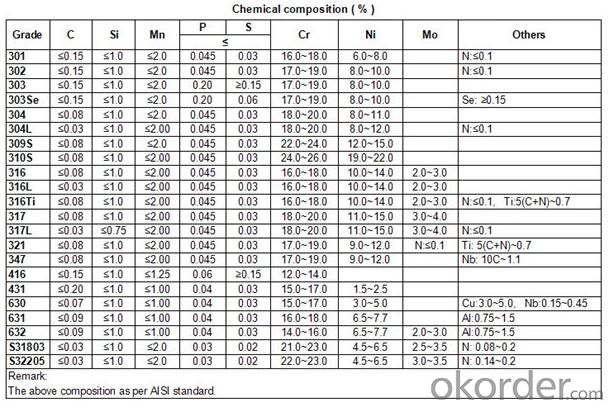

Steel Grade:

A53(A,B),20#,10#,SS400-SS490,600 Series,400 Series,300 Series,Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series

Certification:

SGS,ISO,RoHS,IBR,BV,UL,BSI,API,CE

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: How are stainless steel rods made?

- Under normal circumstances, small specifications can be pulled, the general specifications for more rolling, large specifications for forging, there is a distinction between, the boundaries are not obvious, and equipment, technology and requirements of the different. However, more and more big round billets are continuous casting, and large ones can reach 1000mm diameter.

- Q: How are stainless steel bars used in the food processing industry?

- Stainless steel bars are extensively used in the food processing industry due to their numerous advantageous properties. These bars are primarily utilized for the construction of equipment and machinery that comes into direct contact with food, ensuring the highest level of hygiene and safety. One of the key benefits of stainless steel bars is their corrosion resistance. Food processing involves the use of various acidic, alkaline, and corrosive materials, and stainless steel bars are highly resistant to such elements. This property prevents the bars from rusting or corroding, ensuring that no contaminants are introduced into the food during processing. Furthermore, stainless steel bars are easy to clean and maintain, which is crucial in the food processing industry. They have a smooth surface that does not allow food particles or bacteria to adhere, eliminating the risk of contamination. Additionally, their non-porous nature prevents any absorption of odors, flavors, or colors from the food being processed, maintaining the integrity of the final product. Stainless steel bars also possess excellent mechanical properties, such as high strength and durability, making them ideal for heavy-duty applications. They can withstand extreme temperatures, pressures, and mechanical stresses, ensuring reliable and long-lasting equipment in the food processing industry. In terms of food safety regulations, stainless steel bars meet the stringent standards set by regulatory bodies. They are approved for use in food contact applications and are considered safe and hygienic. This gives confidence to both manufacturers and consumers that the processed food is being handled in a sanitary and reliable manner. Overall, stainless steel bars are indispensable in the food processing industry due to their corrosion resistance, easy maintenance, mechanical strength, and compliance with food safety regulations. They play a vital role in ensuring the production of safe and high-quality food products for consumers worldwide.

- Q: What is the difference between stainless steel bars and stainless steel flats?

- Stainless steel bars and flats are both popular options for various uses due to their durability, ability to resist corrosion, and attractive appearance. However, there are some distinctions between the two. The primary difference lies in their shape. Stainless steel bars are typically cylindrical and have a round cross-section. They come in different diameters, ranging from small to large sizes. On the other hand, stainless steel flats have a rectangular or square cross-section and resemble flat plates or strips. They are available in various widths and thicknesses. In terms of applications, stainless steel bars are commonly utilized in the construction, engineering, and manufacturing industries. They serve as structural components, support beams, and reinforcement materials. Because of their circular shape, they offer excellent tensile strength and can handle heavy loads. Moreover, stainless steel bars can be machined and fabricated into different shapes and sizes to meet specific project requirements. In contrast, stainless steel flats are widely used in architectural, decorative, and design applications. The flat surface of these bars makes them suitable for creating visually appealing structures like handrails, balustrades, and decorative trim. Stainless steel flats are also popular in the kitchen appliance, automotive, and furniture manufacturing industries, where their sleek appearance and resistance to corrosion are highly valued. Another distinction between stainless steel bars and flats is their availability and cost. Stainless steel bars are more readily available in a wide range of sizes and grades, which makes them relatively more accessible and cost-effective. Conversely, stainless steel flats may have fewer options in terms of sizes and grades, which can impact their availability and pricing. To sum up, the main discrepancy between stainless steel bars and flats lies in their shape, with bars being cylindrical and flats having a rectangular or square cross-section. Their applications also differ, with bars commonly used in structural and engineering projects, whereas flats are more frequently utilized in architectural and decorative applications. Additionally, the availability and cost of these two forms of stainless steel may vary.

- Q: Are stainless steel bars suitable for high-temperature applications?

- Yes, stainless steel bars are suitable for high-temperature applications. Stainless steel has excellent heat resistance properties, allowing it to maintain its strength and integrity even at elevated temperatures. Additionally, it exhibits low thermal expansion and good thermal conductivity, making it an ideal material for applications that require resistance to high temperatures.

- Q: Can stainless steel bars be used in pharmaceutical machinery?

- Yes, stainless steel bars can be used in pharmaceutical machinery. Stainless steel is a popular choice in pharmaceutical manufacturing due to its excellent corrosion resistance, hygienic properties, and ease of cleaning. It is commonly used in various components and equipment such as mixers, tanks, conveyors, and valves to ensure product integrity and compliance with strict industry regulations.

- Q: Are stainless steel bars suitable for hydroelectric power plants?

- Yes, stainless steel bars are highly suitable for hydroelectric power plants. Stainless steel is known for its exceptional corrosion resistance, which is crucial in an environment where water is constantly present. It can withstand the corrosive effects of water, moisture, and other chemicals, ensuring the structural integrity and longevity of the bars used in hydroelectric power plants. Additionally, stainless steel bars offer high strength and durability, making them ideal for withstanding the heavy loads and vibrations associated with power generation.

- Q: Can stainless steel bars be used in the oil and gas aftermarket?

- Stainless steel bars, indeed, find utility within the oil and gas aftermarket. With its adaptability and ability to resist corrosion, stainless steel proves itself suitable for a plethora of applications within the oil and gas sector. Specifically, it is frequently employed in the manufacturing of equipment, piping systems, and components that face extreme conditions, such as harsh environments, elevated temperatures, and corrosive substances. The construction of offshore platforms, refineries, pipelines, and storage tanks commonly relies on stainless steel bars due to their remarkable strength, durability, and resistance against corrosion. Consequently, they serve as an ideal choice for utilization in the oil and gas aftermarket.

- Q: Can stainless steel bars be used in the aerospace aftermarket?

- Stainless steel bars are indeed suitable for the aerospace aftermarket. Renowned for their exceptional strength, resistance to corrosion, and long-lasting nature, stainless steel proves to be an excellent material for a range of aerospace uses. In the aerospace sector, one can commonly find stainless steel bars utilized in various components, including aircraft frames, landing gear, engine parts, and fasteners. These bars endure extreme conditions such as high temperatures, pressure, and exposure to harsh chemicals. Stainless steel's remarkable ability to withstand these challenging circumstances while preserving its structural integrity makes it a dependable choice for aerospace aftermarket applications. Moreover, stainless steel bars can be easily machined, welded, and shaped, allowing for customization and precise manufacturing that aligns with specific aerospace requirements. Consequently, stainless steel bars are extensively employed within the aerospace aftermarket to guarantee the safety, efficiency, and durability of aircraft components.

- Q: Can stainless steel bars be used in automotive manufacturing?

- Yes, stainless steel bars can be used in automotive manufacturing. Stainless steel is a popular material choice due to its durability, corrosion resistance, and high strength-to-weight ratio. It is commonly used for various automotive components such as exhaust systems, suspension parts, chassis, and structural elements.

- Q: Are stainless steel bars heat treatable?

- Yes, stainless steel bars can be heat treatable. Heat treatment of stainless steel bars involves heating them to a specific temperature and then cooling rapidly or slowly to achieve desired mechanical properties such as improved hardness, strength, and corrosion resistance.

Send your message to us

1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords