AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

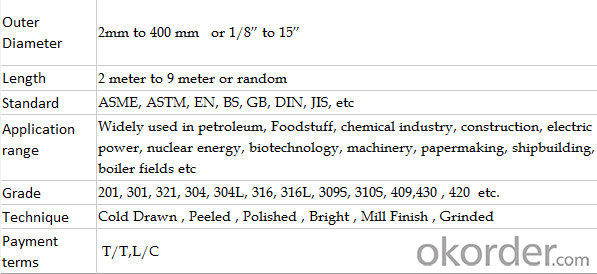

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

Product information:

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What is the modulus of elasticity of a steel round bar?

- Young's modulus, also known as the modulus of elasticity, is a crucial measure when assessing the stiffness and ability of a steel round bar to resist deformation under an external force. Generally, the modulus of elasticity for steel is around 200 GPa. Consequently, when a unit of stress is applied to the steel round bar, it will undergo an elastic deformation ranging from approximately 0.0035 to 0.005, depending on the specific grade and composition of the steel. Hence, the modulus of elasticity plays a significant role in structural and mechanical engineering applications, as it dictates the level of deflection or deformation to be expected under various loading conditions.

- Q: What are the different surface finishes for stainless steel round bars?

- Stainless steel round bars can have different surface finishes depending on the desired aesthetic appeal and functional requirements. Some of the common surface finishes for stainless steel round bars include: 1. Bright Annealed (BA): This is a smooth and highly reflective finish achieved by annealing in a controlled atmosphere. It provides a mirror-like appearance and is often used for decorative applications. 2. Mill Finish: Also known as hot rolled or hot-rolled annealed and pickled (HRAP), this is the untreated surface finish directly from the mill. It has a rough and pitted texture and is commonly used for industrial applications where appearance is not the primary concern. 3. Satin Finish: Also referred to as brushed or dull polished finish, this finish is achieved by brushing the surface of the stainless steel round bar with a fine abrasive material. It creates a soft and matte appearance with visible parallel lines. 4. Polished Finish: This finish is achieved by using progressively finer abrasive materials to polish the surface of the stainless steel round bar. It results in a high-gloss, mirror-like finish that is commonly used for decorative purposes. 5. Ground Finish: This finish is achieved by grinding the surface of the stainless steel round bar using abrasive belts or wheels. It creates a uniform and smooth surface with a matte appearance. 6. Bead Blasted Finish: This finish is achieved by bombarding the surface of the stainless steel round bar with small glass beads at high pressure. It creates a uniform and matte appearance with a slightly textured feel. 7. Electropolished Finish: This finish is achieved by immersing the stainless steel round bar in an electrolytic bath and applying an electric current. It removes a thin layer of material, resulting in a smooth and shiny surface with improved corrosion resistance. Each surface finish has its own unique characteristics and is chosen based on the specific requirements of the application.

- Q: Can steel round bars be cut to custom lengths?

- Indeed, it is possible to cut steel round bars to tailor-made lengths. These bars made of steel are adaptable and can be effortlessly cut using different techniques like sawing, shearing, or torch cutting. These approaches enable accurate adjustments to be made to meet specific demands or project necessities. Moreover, steel round bars are often obtainable in standard lengths, but they can be conveniently shortened or elongated by welding separate pieces together. All in all, steel round bars provide versatility in terms of length customization, rendering them suitable for a diverse array of applications.

- Q: How strong are steel round bars compared to other materials?

- Steel round bars are known for their exceptional strength and durability, making them one of the strongest materials available. Compared to other materials such as aluminum, brass, and wood, steel round bars have a significantly higher tensile strength, which refers to the amount of pulling force a material can withstand without breaking. Steel round bars can also handle higher compressive loads, making them ideal for applications where heavy loads or pressure is involved. In addition to their high strength, steel round bars also exhibit excellent ductility, which means they can be easily shaped or bent without breaking. This characteristic makes steel round bars versatile and widely used in various industries such as construction, automotive, manufacturing, and aerospace. While other materials may have their own unique properties and applications, steel round bars remain a top choice when it comes to strength and reliability. Their ability to withstand high loads, resist deformation, and maintain structural integrity make them a popular choice for structural components, shafts, axles, and many other demanding applications.

- Q: Are steel round bars suitable for automotive applications?

- Steel round bars are an ideal choice for automotive applications. Their exceptional strength, durability, and resistance to corrosion make them a popular choice in the manufacturing of various automotive components. These components include axles, crankshafts, drive shafts, steering components, suspension systems, and chassis construction. Steel round bars possess the necessary strength and rigidity to withstand the demanding conditions of automotive use, such as heavy loads, vibrations, and impact forces. Moreover, they offer versatility and adaptability to different automotive designs and requirements as they can be easily machined, welded, and forged. In summary, steel round bars are not only dependable but also cost-effective for automotive applications.

- Q: How are steel round bars manufactured?

- Steel round bars are manufactured through a process known as hot rolling. This process starts with heating a large steel billet in a furnace until it becomes soft and malleable. The billet is then passed through a series of rollers which compress and shape it into a round bar. The first step in hot rolling is the roughing mill, where the billet is passed through multiple sets of rollers to reduce its thickness and increase its length. This process also helps to ensure that the steel maintains a consistent temperature throughout. After the roughing mill, the bar enters the finishing mill, where it is further reduced in size and given its final shape. The finishing mill typically consists of several sets of rollers that gradually decrease the diameter of the bar while increasing its length. This process is repeated until the desired dimensions are achieved. During the rolling process, the steel round bar is constantly monitored for quality control. Any imperfections or defects that may arise are detected and corrected to ensure the final product meets the required specifications. Once the bar reaches its final dimensions, it is cooled and cut to the desired length. The cooling process can be done using air, water, or a combination of both. After cooling, the bar is inspected for any surface defects and undergoes further processing if necessary. In some cases, additional treatments such as heat treatment or surface finishing may be applied to enhance the properties and appearance of the steel round bar. Overall, the manufacturing of steel round bars involves a combination of heating, rolling, cooling, and cutting processes to produce a high-quality product that meets the specific requirements of various industries.

- Q: What are the advantages of using nickel-chromium-titanium alloy steel round bars?

- There are several advantages of using nickel-chromium-titanium alloy steel round bars: 1. High Strength: Nickel-chromium-titanium alloy steel round bars are known for their exceptional strength and durability. They have a high tensile strength, making them suitable for applications requiring heavy-duty materials. 2. Corrosion Resistance: These alloy steel round bars have excellent corrosion resistance properties due to the presence of nickel and chromium. This makes them ideal for use in environments where exposure to moisture, chemicals, or harsh conditions is common. 3. Heat Resistance: Nickel-chromium-titanium alloy steel round bars can withstand high temperatures without losing their mechanical properties. They exhibit good heat resistance, making them suitable for applications in industries such as aerospace, power generation, and automotive. 4. Fatigue Resistance: The unique composition of nickel-chromium-titanium alloy steel round bars provides excellent fatigue resistance, allowing them to withstand repeated stress and load cycles without deformation or failure. This makes them suitable for applications in high-stress environments. 5. Machinability: Despite their high strength and toughness, nickel-chromium-titanium alloy steel round bars are relatively easy to machine. They can be easily cut, drilled, or shaped, allowing for efficient and precise manufacturing processes. 6. Versatility: These alloy steel round bars have a wide range of applications due to their versatile properties. They can be used in industries such as construction, automotive, aerospace, marine, and many more. Their high strength and corrosion resistance make them suitable for various structural and load-bearing applications. Overall, nickel-chromium-titanium alloy steel round bars offer a combination of high strength, corrosion resistance, heat resistance, fatigue resistance, machinability, and versatility, making them a preferred choice for many industrial applications.

- Q: What are the different surface treatments available for tool steel round bars?

- Some of the different surface treatments available for tool steel round bars include: 1. Nitriding: This process involves diffusing nitrogen into the surface of the tool steel, which improves hardness, wear resistance, and corrosion resistance. 2. Hard Chrome Plating: This treatment involves applying a layer of chromium to the surface of the tool steel, which enhances hardness, wear resistance, and resistance to corrosion. 3. Black Oxide Coating: This treatment involves a chemical reaction that creates a black oxide layer on the surface of the tool steel, providing improved appearance and some corrosion resistance. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that deposits a thin film coating onto the surface of the tool steel. Different types of PVD coatings can improve hardness, lubricity, and resistance to wear and corrosion. 5. DLC Coating: Diamond-Like Carbon (DLC) coating is a type of PVD coating that incorporates carbon to provide enhanced hardness, low friction, and wear resistance. 6. Powder Coating: This process involves applying a dry powder coating to the surface of the tool steel, which is then cured to create a durable and attractive finish. These surface treatments can be chosen based on the specific requirements of the tool steel application, such as improving wear resistance, reducing friction, enhancing appearance, or providing corrosion resistance.

- Q: What are the different types of finishes available for steel round bars?

- Steel round bars offer a variety of finishes, each with its own unique properties and appearance. 1. Mill Finish: The most commonly used finish is the mill finish, where the steel is left in its natural state after rolling and cooling. This results in a rough texture and the possibility of surface imperfections. 2. Hot Rolled Finish: Achieved by heating the steel to high temperatures and shaping it through rolling. This finish provides a smooth surface and is typically used in applications where aesthetics are not a priority. 3. Cold Drawn Finish: Involves pulling the steel through a die to reduce its diameter and increase its length. This finish offers a smooth surface, improved dimensional accuracy, and tighter tolerances. 4. Polished Finish: Steel round bars can be polished to achieve a smooth and reflective surface. This is done using abrasive materials or compounds to remove imperfections and enhance appearance. 5. Ground Finish: A process that involves removing a thin layer of material from the steel surface using abrasive grinding wheels. This creates a smooth and even finish suitable for applications that require precise dimensions and tight tolerances. 6. Coated Finish: Steel round bars can be coated with different materials for added protection against corrosion or to enhance appearance. Common coatings include galvanization, which applies a layer of zinc, and powder coating, which provides durability and a decorative finish. When choosing a finish for a steel round bar, it is important to consider the specific application and desired properties. Factors such as corrosion resistance, aesthetics, dimensional accuracy, and surface quality should be taken into account.

- Q: What are the advantages of using low-alloy steel round bars?

- One advantage of using low-alloy steel round bars is its increased strength and durability compared to regular carbon steel. This makes it suitable for applications that require high tensile strength and resistance to wear and tear. Additionally, low-alloy steel round bars generally offer better weldability and machinability, allowing for easier fabrication and modification. Overall, low-alloy steel round bars provide a cost-effective solution for various industries, including construction, automotive, and manufacturing.

Send your message to us

AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords