Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Made in China stainless steel chimney pipe

Our Services

We assure you:

Small MOQ + Cheap Price + Good Quality + Fast Delivery

OUR STRENGTH

1.100% Manufacturer.

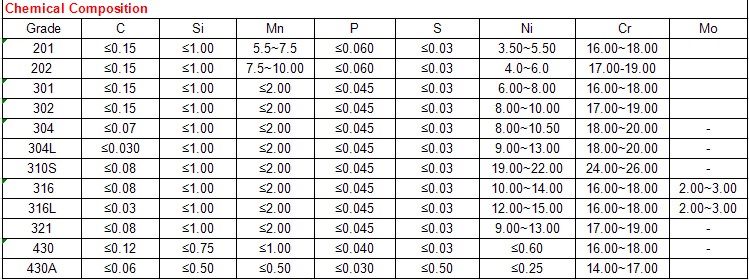

2. Specializing in processing 200 / 300 / 400 / 900 series stainless steel.

3. Well-trained and experienced staffs.

4. Able to answer all your enquiries in fluent English.

5. Russian enquiries can be well understand and replied

FAQ

1. Small quantity, short time delivery

If we have stocks, we can ship from a minimum of 1 kg sample in a few days. We also manufacture custom-order materials in amounts of 300 kg and up (Some materials are allowed 50 kg) in as few as 3 weeks.

2. High-precision thickness

We guarantee thickness tolerances that cannot be reproduced by competitors.

Example:

t <0.30mm tolerance ±1 - 3 μm guaranteed

0.30 mm≤t Tolerance ± 1% guaranteed

3. Ability to add multiple features

We are capable of adding a variety of features to metallic materials(resin coating, plating, bonding different kinds of metal, multigage skiving, etc.).

4. Unique technology and custom-made solutions

We provide customed solutions to your problems with our unique technologies and well versed knowledge of materials acquired through our experience of manufacturing 50,000 items.

5. Choose the appropriate base metals for your needs.

We carefully balance quality, delivery time and price,procure various base metals from all over the world.

We manufacture appropriate products to your needs.

6. To control metal structure(chemical formation)

We can manufacture ultrafine metal structures with a grain size of 1 μm. Using finer grain sizes provides benefits such as hardenability,balancing strength and ductility, and precision press processing.

7. Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

8. Global network

Our plant located in Japan, Shanghai and Taiwan,we also support flexibly local procurement and production transfer.

- Q: Can stainless steel pipes be heat treated?

- Indeed, heat treatment is applicable to stainless steel pipes. The procedure entails subjecting the stainless steel pipe to a particular temperature, maintaining it at that temperature for a specific duration, and subsequently cooling it in a controlled manner. This method is commonly employed to modify the mechanical properties of the stainless steel, such as enhancing hardness or bolstering strength. Furthermore, heat treatment can address stress relief and eliminate impurities in the stainless steel pipe. However, it is crucial to acknowledge that not all stainless steel grades can undergo heat treatment, as the composition of the alloy significantly influences its heat treatability. Therefore, it is advisable to consult the manufacturer or a metallurgical expert to ascertain the appropriate heat treatment process for a specific stainless steel pipe.

- Q: Are stainless steel pipes suitable for industrial water systems?

- Yes, stainless steel pipes are suitable for industrial water systems. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for use in water systems that are exposed to harsh conditions and high levels of moisture. Stainless steel pipes have excellent resistance to both internal and external corrosion, which reduces the risk of leaks and contamination in industrial water systems. They also have a long lifespan and require minimal maintenance, resulting in cost-effectiveness in the long run. Additionally, stainless steel pipes have a high heat resistance, making them suitable for applications that involve hot water or steam. Overall, stainless steel pipes are a reliable and efficient choice for industrial water systems.

- Q: Can stainless steel pipes be insulated with neoprene?

- Neoprene insulation is capable of being applied to stainless steel pipes. Neoprene, a highly adaptable and long-lasting material renowned for its exceptional insulation qualities, is frequently employed to insulate a variety of pipe types, including stainless steel. Neoprene insulation can successfully lessen heat loss or gain, avert condensation, and furnish defense against extreme temperatures. Additionally, it possesses resistance to moisture, chemicals, and UV radiation, rendering it an appropriate choice for a diverse array of applications. Correct installation of neoprene insulation can effectively heighten the energy efficiency and performance of stainless steel pipes.

- Q: Can stainless steel pipes be used for underground sprinkler systems?

- Underground sprinkler systems can indeed utilize stainless steel pipes. Stainless steel is renowned for its durability, corrosion resistance, and capacity to withstand extreme pressure and temperature. These characteristics render it an exceptional option for subterranean applications, where pipes are exposed to moisture, soil, and various environmental elements. Moreover, stainless steel pipes are non-reactive, guaranteeing that they won't pollute the water supply or compromise the quality of the irrigation water. Nevertheless, it is crucial to ensure the proper installation of stainless steel pipes, including suitable fittings and connections, to guarantee a dependable and effective sprinkler system.

- Q: Are stainless steel pipes suitable for petrochemical plants?

- Yes, stainless steel pipes are highly suitable for petrochemical plants. They possess excellent corrosion resistance, high temperature strength, and durability, making them ideal for handling various aggressive chemicals and fluids found in petrochemical processes. Additionally, stainless steel pipes can withstand high pressure and maintain their structural integrity, ensuring the safety and longevity of the plant's operations.

- Q: How are stainless steel pipes graded?

- The quality and suitability of stainless steel pipes are determined by various factors, resulting in their grading. The grading system takes into consideration factors such as chemical composition, mechanical properties, and manufacturing process. When grading stainless steel pipes, a crucial aspect is their chemical composition. This refers to the specific elements present in the alloy and their quantities. Common elements found in stainless steel pipes are chromium, nickel, molybdenum, and carbon. The percentage of these elements affects the strength, durability, and corrosion resistance of the pipes. Different grades of stainless steel pipes have different compositions, allowing them to be used in various environments and applications. Another factor considered in grading stainless steel pipes is their mechanical properties, including tensile strength, yield strength, and elongation. These properties determine how the pipes perform under different conditions and their structural integrity. Higher grades of stainless steel pipes generally possess superior mechanical properties, making them suitable for applications involving high pressure and temperature. The manufacturing process also plays a vital role in grading stainless steel pipes. The pipes undergo processes such as hot rolling, cold rolling, and heat treatment to shape them and enhance their properties. The quality of the manufacturing process greatly impacts the final grade of the stainless steel pipes. Pipes produced using advanced techniques and strict quality control measures are usually assigned higher grades. In conclusion, stainless steel pipes are graded based on their chemical composition, mechanical properties, and manufacturing process. These grading criteria ensure that different grades of stainless steel pipes are available to meet the specific requirements of different industries and applications.

- Q: How do you prevent vibration in stainless steel pipes?

- To prevent vibration in stainless steel pipes, various measures can be taken: 1. Employ suitable pipe supports: It is imperative to carefully select and install appropriate pipe supports. These supports should be designed to offer ample stability and rigidity to the pipe system, minimizing any potential movement or vibration. 2. Mitigate vibrations with isolators: Strategic placement of vibration isolators along the pipe system can help absorb and dampen vibrations. This reduces the transmission of vibrations through the stainless steel pipes. 3. Ensure proper pipe alignment: During installation, ensure that the pipes are aligned correctly. Misalignment can lead to stress concentrations and heightened vibration. Proper alignment helps distribute forces evenly and reduces vibration. 4. Decrease fluid velocity: High fluid velocities can induce turbulence and vibrations in the pipe system. By reducing the fluid velocity, either through adjusting the flow rate or utilizing flow control devices like throttling valves, vibrations can be minimized. 5. Implement soundproofing measures: In certain cases, vibrations may be caused by external factors, such as nearby machinery or equipment. To reduce noise and vibrations originating from these sources, consider implementing soundproofing measures like using noise-absorbing materials or installing vibration-blocking barriers. 6. Regularly maintain and inspect the pipe system: Conduct routine inspections to detect any signs of vibration or wear in the pipe system. Address any issues promptly to prevent further vibration problems. Additionally, ensure proper maintenance of the pipe system, including regular cleaning and lubrication of any moving parts. By implementing these measures, vibration in stainless steel pipes can be effectively prevented, ensuring the overall stability and integrity of the pipe system.

- Q: Are stainless steel pipes suitable for brewery applications?

- Stainless steel pipes prove to be highly suitable for brewery applications with their exceptional corrosion resistance, durability, and hygienic properties, making them the preferred material in the brewing industry. These pipes can endure the challenging conditions of a brewery environment, including exposure to hot liquids and cleaning chemicals, without succumbing to corrosion or contaminating the beer. Furthermore, the smooth surface of stainless steel pipes aids in preventing the accumulation of bacteria and other impurities, ensuring a superior level of cleanliness and quality throughout the brewing process. Moreover, stainless steel is effortlessly cleaned and maintained, adding to its practicality for breweries. In conclusion, stainless steel pipes are a dependable and efficient choice for brewery applications.

- Q: What kind of stainless steel square tube is used in ordinary square tubes?

- Stainless steel tube is widely used, of course, there are certain reasons, of which the most important is its long service life, good corrosion resistance, and lighter weight, but the strength of large, reduce the load for the product, increase its capacity, so that consumers with more rest assured.

- Q: 310 stainless steel resistance to high temperature?

- American brand 310S, also known as 2520, used in high temperature furnace tube manufacturingMain features: austenitic stainless steel

Send your message to us

Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords