API Seamless Steel Line Pipe ASTM A53 ASTM A 106 For Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe:

Seamless pipe holds a hollow section and there is no seam around. It is made with steel bar by perforating machine and is of better pressure resistance than other forms, and was usually more easily available and safe. We are factory and definitely will satisfy your demand. We can make pipes according to your requirement and under your inspection.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

Our products are strictly in accordance with international standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund. So you don't have to be hesitate about placing orders. It is safe and we are honest and want to state long-time business relationship with you.

②How about the price?

Yes, we are factory and offering you the lowest price in the market. what's more, speed and honesty are our target. get good service from us. No hesitate. But if you like bargain and factory price is not low enough as you think, just don’t waste your time. Please trust the quotation we would give you, it is professional one.

③Why should you choose us?

Think of our quality and price. They are charming. SGS test / Customer inspection / Third party inspection is OK. We are factory. So we can make any pipe you need in accordance to your requirement. We emphasize the importance of after-sale service. You will get good service as well. That's attaracting. Contact us ASAP.

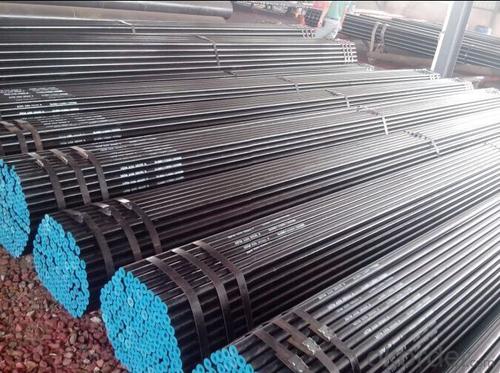

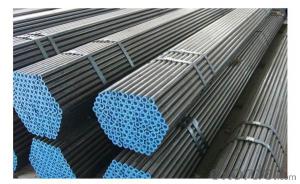

6、Seamless Pipe Images:

- Q: What is the difference between steel pipes and PVC-U pipes?

- Steel pipes and PVC-U pipes differ in terms of their composition, strength, and suitability for different applications. Steel pipes are made from iron and carbon, making them strong and durable, capable of withstanding high pressure and extreme temperatures. They are commonly used for transporting liquids and gases in industries like oil, gas, and construction. On the other hand, PVC-U pipes are made from polyvinyl chloride, a plastic material. They are lightweight, easy to install, and resistant to corrosion and chemicals. PVC-U pipes are typically used for water supply, drainage systems, and irrigation.

- Q: How are steel pipes tested for quality?

- Steel pipes are tested for quality through various methods, including visual inspection, non-destructive testing (NDT) techniques such as ultrasonic testing, magnetic particle testing, and radiographic testing. Additionally, mechanical properties like tensile strength, hardness, and toughness are evaluated to ensure the pipes meet the required specifications. Various standards and guidelines are followed to ensure the quality and safety of steel pipes.

- Q: How is the steel pipe dance installed at home?

- Perforated steel pipe, is very troublesome, need support to the roof and drilling in the room, the bottom with tripod frame fixed nail, and welding, installation is very troublesome;

- Q: How are steel pipes insulated against heat loss?

- Steel pipes can be insulated against heat loss using several methods. One common method is through the use of insulation materials such as mineral wool or fiberglass wraps. These materials are wrapped around the pipes to create a barrier that reduces heat transfer. Another method is the application of insulation coatings, such as foam or rubber coatings, directly onto the surface of the pipes. These coatings create a protective layer that minimizes heat loss. Additionally, thermal tape or heat-resistant tape can be used to seal any gaps or joints in the insulation, ensuring a continuous barrier against heat loss. Overall, insulating steel pipes against heat loss is essential to maintain the temperature of the fluid or gas being transported and to increase energy efficiency in various industries.

- Q: How are steel pipes inspected for quality?

- Steel pipes are inspected for quality through various methods such as visual inspection, non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, and radiographic testing. These inspections help identify any defects, cracks, or imperfections in the pipes, ensuring they meet the required quality standards. Additionally, mechanical tests such as tensile strength and hardness tests may also be conducted to assess the structural integrity of the steel pipes.

- Q: Are steel pipes recyclable?

- Yes, steel pipes are recyclable.

- Q: How are steel pipes used in the manufacturing of solar power systems?

- Steel pipes are commonly used in the manufacturing of solar power systems for various purposes. They are used as structural supports for solar panels, providing stability and durability. Additionally, steel pipes are often utilized for the transportation of fluids such as water or heat transfer fluids, enabling the efficient circulation of these substances within the solar power system.

- Q: What quota is reserved for buried DN20 steel pipe?

- It is an embedded sleeve control sub item, if the reserved hole, then there is no need to cover, special subject structure adjustment factor of the cost of the water supply and drainage engineering, water supply and drainage engineering he is buried under the charge.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are widely used in the mining industry for various purposes such as transporting water, slurry, and other fluids, as well as for ventilation and structural support in underground mines. Their durability, resistance to corrosion, and high pressure capacity make them ideal for these applications.

- Q: What are the different types of coatings used on steel pipes?

- Steel pipes can be coated with various types of coatings to increase their durability and protect them from corrosion. Some commonly used coatings are: 1. Fusion-Bonded Epoxy (FBE) Coating: The steel pipe is heated and the epoxy powder is melted and fused to the surface. FBE coatings offer excellent corrosion resistance and are widely used in water pipelines and the oil and gas industry. 2. Polyethylene (PE) Coating: Similar to FBE coatings, PE coatings are applied to steel pipes. They provide a protective layer that is resistant to moisture, chemicals, and abrasion. PE coatings are commonly used in gas pipelines and underground water pipelines. 3. Polypropylene (PP) Coating: PP coatings have similar application processes and protective qualities as PE coatings. However, they offer enhanced resistance to higher temperatures, making them suitable for chemical processing plants and refineries. 4. Concrete Weight Coating (CWC): This special coating involves applying a layer of concrete to the steel pipe. It adds weight to the pipe, making it more stable and resistant to buoyancy in underwater or submerged applications. 5. Zinc Coating: Zinc coatings, such as hot-dip galvanizing, involve immersing the steel pipe in molten zinc. This creates a protective layer of zinc on the pipe's surface, offering excellent corrosion resistance. Zinc coatings are commonly used in outdoor applications, such as fencing, guardrails, and water pipelines. 6. Bituminous Coating: Bituminous coatings involve applying a layer of bitumen or asphalt to the steel pipe. They provide excellent resistance to water and chemicals, making them suitable for underground pipelines and structures. These examples illustrate the variety of coatings available for steel pipes. The choice of coating depends on factors like the intended application, environmental conditions, and desired level of corrosion resistance.

Send your message to us

API Seamless Steel Line Pipe ASTM A53 ASTM A 106 For Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords