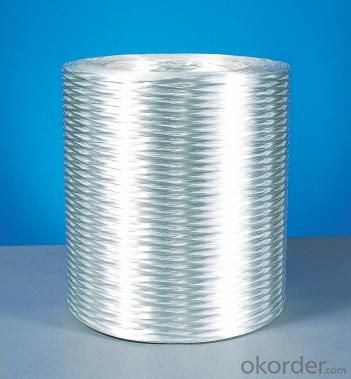

AR Glassfiber Spray Roving for Concrete

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AR Glassfiber Spray Roving for Concrete:

1,Diameter:15Micron

2,Linear density:2400tex

3,Package:by pallet

Description of AR Glassfiber Spray Roving for Concrete:

Alkali-resistant fiberglass spray uproving is made of AR strand,it has significant alkali resistance because containing ZrO2 composition.

Product Specification of AR Glassfiber Spray Roving for Concrete:

ARC15-2400-14.5/16.5

AR: Alkali resistant glass

C:continuous fiber

15:fiber filament diameter

2400:roving yarn density

14.5/16.7:ZrO2 content

Features of AR Glassfiber Spray Roving for Concrete:

1,No fuzz,easy chopped

2,Good integrity,dispersibility

3,Good alkali-resistant and corrosion-resistant persistence

Typical applications of AR Glassfiber Spray Roving for Concrete:

Alkali-resistant fiberglass is the Inorganic fibers,mainly used for fiberglass enhancing cement contrete,the ideal substitute for steel and asbestos in non-load bearing concrete components.It is a new type of green environmental protection enhancing material which is widely used for the high performance enhanced concrete.

- Q: I was wondering because I'm making a base for my heavy bag stand and I found a really strong old tire (with the rim) and I already have the cement I just need to know how to fill it with cement and how to put the pole in it also.

- Lay it down on ground, fill the center with sand up to inside lip of tire, about 3. Fill with cement up to upper inside lip of tire. Don't worry about removing air inside top part, the air gap will not hurt. Place a steel pipe in it with threaded end that sticks up several inches to attach pole.

- Q: should i get white cement 4's or galaxy foamposites?

- The white cement 4's because its gonna be hella hard to get ur hands on the galaxy foamposites there gonna be super limited quick strike but good luck on all accounts.

- Q: or can i just start laying it directly on top of the cement floor?

- You can lay tile directly on cement floor.

- Q: Should I be a Stonemason or a Cement Mason?

- Not sure if this fits in Hobbies Crafts, but my impression is that a Stone Mason is a skilled profession requiring a fair amount of training to claim that title and a Cement Finisher is a far lower level common labor job - I had to do my own cement framing and finishing while redoing my garage in sections, and while I hated the work involved, I didn't encounter surprises from the information dragged from the Internet.

- Q: I just bought this model and it's my first one doing it lol I was just curious that if after I painted one part and went to glue another onto the painted plastic, will it stick? Or will something else bad happen, or will it be perfectly fine? I just don't want to ruin it =( The glue I have is Testors Cement for Plastic Models and the paint is also Testors Enamel paint.

- The cement will probably dissolve the paint and you'll get a messy joint. Scrape the paint away at the places you want to glue.

- Q: Are they just two different terms for the same thing?

- Cement should not be confused with concrete as the term cement explicitly refers to the dry powder substance. Upon the addition of water and/or additives the cement mixture is referred to as concrete, especially if aggregates have been added.

- Q: For a science projekt i need to use a material that is stronger than plaster but not to heavy like cement or if u know a brand of plaster that is really strong or vice versa with cement please tell me. it would be great If the cost is less than 50 dollars for 10kg than

- Aerate the cement and it should hold most of its structural integrity as well as reduce the overall mass.

- Q: What is the best thing to write in wet cement?

- This cement is now dry. or There is a dead body under here LOL Cheers from Australia

- Q: How much would it cost to fill a circle, with a diameter of 20 feet, with Cement if the depth into the ground was a foot?

- How about we call it 12 yards and our price here is 100 a yard plus tax.... so all you need now is someone to pour and finish it:) Have fun, 12 is deep, so watch the little kids.......they just love to skate thru.

- Q: They all seem to refer to the same thing, is it determined based on how each is used on context or are all interchangeable with each other?

- asphalt --- A sticky, black and pretty viscous liquid or semi-reliable, composed especially a lot completely of bitumen, it truly is cutting-edge in maximum crude petroleums and in some organic deposits. pavement --- (mainly British) A paved footpath on the area of a highway. --- (US) Any paved outdoors floor, as with a highway or sidewalk. --- the interior flooring, fairly even as of stone, of massive homes including a cathedral. --- the textile with which a floor is paved. cement --- contained in the most commonplace experience of the note, a cement is a binder, a substance which gadgets and hardens independently, and would bind different resources mutually. Concrete could not be at a loss for words with cement because the time period cement refers in reality to the dry powder substance used to bind the mixture resources of concrete. Upon the addition of water and/or aspects the cement mix is termed concrete, fairly if aggregates were further.

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

AR Glassfiber Spray Roving for Concrete

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords