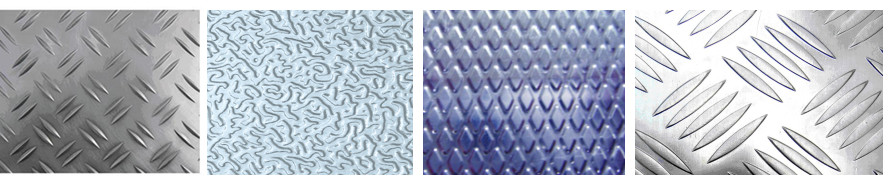

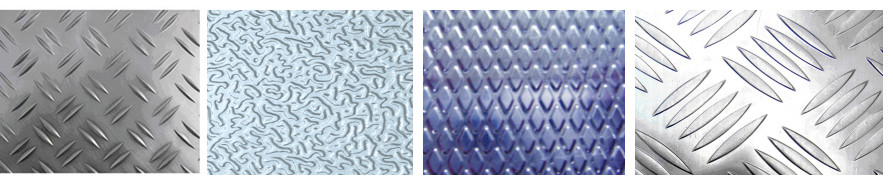

Anti Slippery Aluminum Galvanized Sheets Cleveland

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textured Aluminum Sheet Tread Plate , Five Bars Embossed Aluminum Sheet

Aluminum Plate, Aluminum Sheet, Aluminum Roll, Aluminum Coil, Aluminum Alloy

Product | Textured Aluminum Sheet Tread Plate , Five Bars Embossed Aluminum Sheet

|

Material | 3003(3000 series) |

Status | H14 |

Thickness | 0.5-2.0mm |

Aluminum content | ≥ 95.00% |

Surface | mill finish,no scratching,without burrs |

Property | good extensility,anti-corrosion,good welding performance |

Technical standard | GB/T3880-2006 |

Brand name | CNBM |

Division | Alloy | Application | Feature |

1000 SERIES | 1050 1060 1070 1200 | Utensil, decoration, Reflecting plate, Printing plate, heatproof plate | -Easy to process and weld, resistant to rust, High conductibility of electricity and heat, low strength -Kinds of Cookware |

3000 SERIES | 3003 3005 3105 | Utensil (F/P, inside of rice cooker), aluminum can, material for interior and exterior of building, Celluar Phone | -A3003 : Anodizing Cookwares, general wares, frying pan, coating, Pressure cooker, electric rice cooker, Utensil, Mobile Phone cover & Battery Case Cheaper item with standard quality |

5000 SERIES | 5083 5052 5754 5A05 | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools Automobile Components: | Easy to process and weld and superior hardness &heatproof |

6000 SERIES | 6061 6063 | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc. | -Easy to process , resistant to rust, superior surface treatment |

8000 SERIES | 8011 | Kitchen utensils, Bottle cap | -8000 series is durable to process with special alloy. |

- Q: Can the aluminum sheets be used for heat dissipation purposes?

- Yes, aluminum sheets can be used effectively for heat dissipation purposes due to their excellent thermal conductivity.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: How do you join aluminum sheets together?

- To join aluminum sheets together, there are various methods available depending on the specific application and desired joint strength. The following techniques are commonly used: 1. Welding: Aluminum can be welded using gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), or laser welding. These processes involve melting the aluminum at the joint and introducing a filler material to create a strong bond. Welding offers excellent strength and durability, but it requires skill and suitable equipment. 2. Riveting: Aluminum sheets can be fastened together using rivets. This technique involves drilling holes through the sheets and using a rivet gun to insert and deform a rivet, creating a secure joint. Riveting is a relatively simple and quick method, but its strength may not match that of welding. 3. Adhesive bonding: Industrial adhesive bonding is a popular method for joining aluminum sheets. Specialized adhesives formulated for aluminum bonding are applied to the surfaces, which then cure and form a strong bond. Adhesive bonding is advantageous as it evenly distributes stress and can join dissimilar materials. However, it may not be suitable for high-temperature or high-stress applications. 4. Mechanical fasteners: Aluminum sheets can be fastened together using screws, bolts, or nuts. This involves drilling holes and using fasteners to secure the sheets. Mechanical fasteners provide good strength and allow for disassembly if needed. However, they may require additional maintenance and can cause stress concentrations around the holes. 5. Clinching: Clinching is a cold joining method where aluminum sheets are pressed together using a punch and die. This process deforms the materials and creates a mechanical interlock, resulting in a strong joint. Clinching is a quick and cost-effective method, although it may not be suitable for thin or highly rigid sheets. Ultimately, the choice of joining method depends on factors such as the required strength, aesthetics, cost, and ease of fabrication. It is advisable to seek guidance from a qualified professional or follow specific guidelines to ensure a successful and reliable joint.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets used for food packaging and handling must undergo specific surface treatments to meet hygiene and safety standards. The surface treatment requirements for aluminum sheets in the food industry typically involve processes like cleaning, degreasing, and anodizing. These treatments remove any dirt, oils, or contaminants, and create a protective layer on the aluminum surface to prevent corrosion and ensure the sheets are safe for food contact. Additionally, the surface treatments may also include specific coatings or laminations to enhance the barrier properties and maintain the quality and freshness of the food products.

- Q: What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets typically ranges between 69 GPa and 73 GPa.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically determined by the specific alloy and thickness of the sheets. Aluminum has a relatively low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can deform or melt under high heat. However, it is worth noting that aluminum is a non-combustible material and does not contribute to the spread of fire. Its fire resistance can be enhanced through the use of fire-resistant coatings or by combining it with other fire-resistant materials. Ultimately, it is important to consult with manufacturers or industry experts to determine the fire rating of specific 101 aluminum sheets.

- Q: Can aluminum sheet be used for packaging applications?

- Certainly! Packaging applications can definitely make use of aluminum sheet. The packaging industry widely employs aluminum due to its exceptional qualities. Its lightweight nature, strength, durability, and ability to be molded make it perfect for packaging diverse products. Aluminum sheets can be easily shaped into different forms and sizes, offering tailored packaging solutions. Moreover, aluminum boasts excellent barrier properties, guarding against moisture, gases, and light, which helps maintain the freshness and quality of packaged goods. Additionally, aluminum is non-toxic and can be effortlessly recycled, making it an environmentally friendly choice for packaging applications. In conclusion, aluminum sheet is a versatile and dependable material for packaging various items, such as food, beverages, pharmaceuticals, cosmetics, and more.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- You can clean it with detergent of carburetor, and buy it in auto accessories shop.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: Are aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its lightweight, high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. It is used in aircraft structures, wings, fuselages, and other components to provide durability and fuel efficiency.

Send your message to us

Anti Slippery Aluminum Galvanized Sheets Cleveland

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords