Aluminum Coil Anodizing Aca Corporation F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

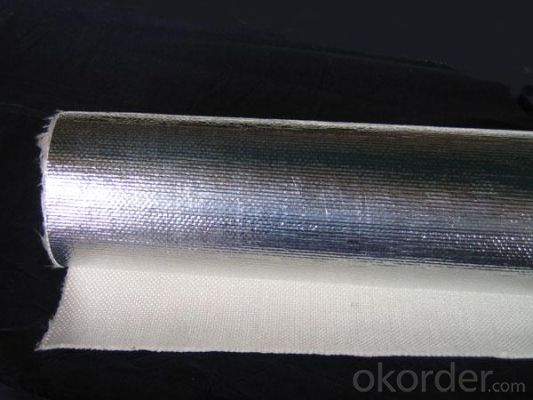

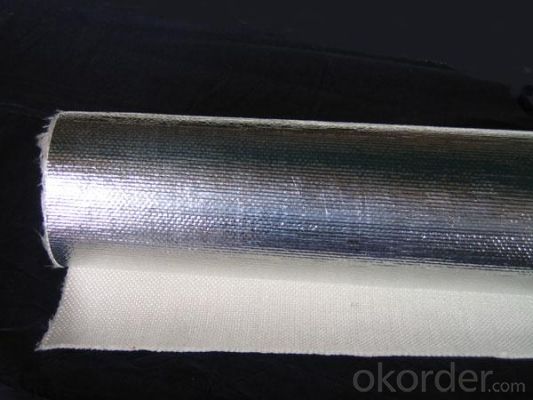

l Product Construction:

Composition | Description | Value (English) | Value (Metric) |

Foil | Aluminum | 0.28 mil | 7 micron |

Reinforcing - MD | Fiberglass | 2 / inch | 8 / 100mm |

Reinforcing - XD | Fiberglass | 3 / inch | 12 / 100mm |

Kraft | Natural | 49 lbs / 3000 ft2 | 80gsm |

Adhesive | Flame-Retardant Glue | ------ | ------ |

Foil | Aluminum | 0.28 mil | 7 micron |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden

pallets, waterproof paper and plastic coverage or or

as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance

payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

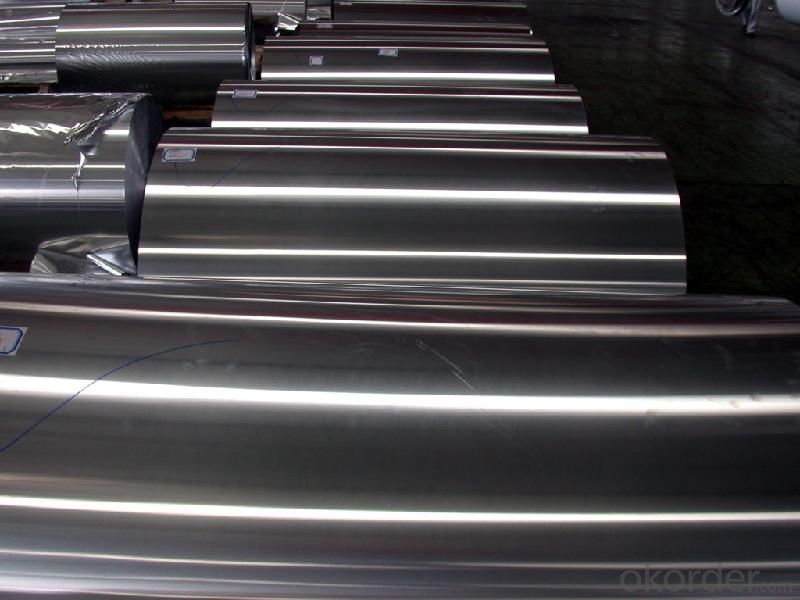

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: also, can aluminum become oxidized when secured down with metal nuts and bolts vice stainless steel nuts and bolts?

- The oxidation is the white powdery stuff on the metal. It can be cleaned with aluminum cleaner. Exposure to the weather can cause the rust, electric current. I advise using a sealer on the metal to keep it clean.

- Q: Are aluminum coils suitable for chemical processing applications?

- Indeed, aluminum coils prove to be fitting for chemical processing applications. Renowned for its outstanding resistance to corrosion, aluminum emerges as the perfect material for deployment in environments that harbor chemicals. Its ability to withstand numerous acids, alkalis, and solvents guarantees the longevity and sturdiness of the coils. Moreover, aluminum coils boast remarkable heat conductivity, enabling efficient heat transfer throughout the chemical processing procedure. Their lightweight composition further facilitates hassle-free handling and installation. Collectively, aluminum coils emerge as a dependable option for chemical processing applications owing to their corrosion resistance, heat conductivity, and durability.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to titanium coils.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- Aluminum, okorder /

- Q: I want to know when it comes to racing which is better? I have a 24 inch aluminium bmx frame and want to know if chromoly frames are faster? Also before buying parts for my bike should I go all aluminum like the bars and forks? Also which is faster the aluminum or the chromoly frame?

- problematic problem. research in yahoo. this will help!

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils contribute to the electrical conductivity of products due to their excellent electrical conductivity property. When electrical current is passed through aluminum coils, they allow the flow of electrons with minimal resistance, enabling efficient transmission of electricity and enhancing the overall conductivity of the product.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum coils are lightweight, which makes them an excellent choice for automotive manufacturers as it helps to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and performance. Additionally, aluminum coils have excellent heat conductivity, which is crucial in automotive applications where heat dissipation is important. Moreover, aluminum coils have good corrosion resistance, which is particularly beneficial in automotive applications where vehicles are exposed to various weather conditions and road salts. Overall, the use of aluminum coils in automotive applications can provide several advantages such as weight reduction, improved fuel efficiency, better heat dissipation, and enhanced corrosion resistance.

- Q: Can aluminum coils be used in high-pressure applications?

- No, aluminum coils are not typically used in high-pressure applications due to their lower strength and less resistance to deformation compared to other materials such as steel.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a lightweight and durable material, making it ideal for furniture production. It is commonly used in the construction of outdoor furniture, as it is resistant to rust and corrosion. Aluminum coils can be formed into various shapes and sizes to create different furniture pieces. Additionally, aluminum can be easily customized and finished with different coatings or paint to match any desired aesthetic. Overall, aluminum coils are a versatile and practical choice for furniture manufacturing.

Send your message to us

Aluminum Coil Anodizing Aca Corporation F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords