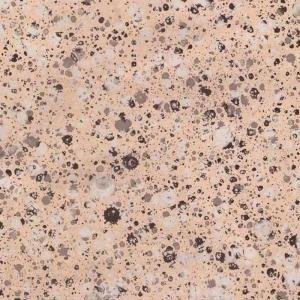

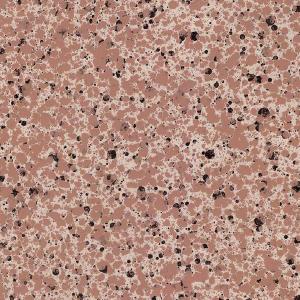

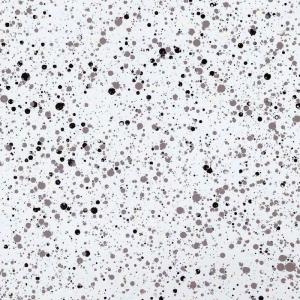

1050 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: Are there any limitations on the surface treatment of aluminum coils?

- The surface treatment of aluminum coils has certain limitations. One limitation pertains to the type of surface treatment suitable for aluminum coils. Anodizing, painting, and powder coating are some options for surface finishes. However, not all treatments are suitable for every application. For instance, anodizing is a durable and corrosion-resistant finish but may not meet the requirements of applications that demand specific colors or designs. Similarly, painting and powder coating offer a wide range of colors and aesthetics but may not match the durability of anodizing. Another limitation concerns the size and shape of the aluminum coils. Surface treatment processes have size and shape restrictions for aluminum coils. For example, anodizing is typically performed in tanks or racks, which may have size limitations. Similarly, painting and powder coating processes may require specific equipment or facilities that cannot accommodate large or irregularly shaped coils. Furthermore, the condition of the aluminum surface affects the effectiveness of the surface treatment. Imperfections or surface defects on aluminum coils can impact the adhesion and durability of the treatment. Proper cleaning and preparation of the aluminum surface are crucial to ensure the effectiveness of the surface treatment. In conclusion, while there are various surface treatments available for aluminum coils, limitations exist regarding the type of treatment, the size and shape of the coils, and the condition of the aluminum surface. It is important to consider these limitations and select the most suitable surface treatment based on the specific requirements and constraints of the application.

- Q: Are aluminum coils compatible with other materials?

- Indeed, other materials can be used in tandem with aluminum coils. Aluminum, being a versatile and extensively utilized substance, readily blends with various materials for different purposes. Take, for instance, the utilization of aluminum coils alongside copper tubing in air conditioning and refrigeration systems to amplify heat transfer efficiency. Furthermore, aluminum coils can be coated or layered with polymers or paints to furnish supplementary safeguard against corrosion, enhance visual appeal, or elevate specific performance attributes. Consequently, aluminum coils exhibit compatibility with a multitude of materials, rendering them apt for an array of applications within industries like construction, automotive, aerospace, and beyond.

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- Could you not just recycle the aluminium food containers? Its a lot better than alternatives like plastic.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are resistant to UV rays.

- Q: How do aluminum coils contribute to energy-efficient insulation?

- The role of aluminum coils in enhancing energy-efficient insulation cannot be overstated. To begin with, aluminum is an exceptional heat conductor, allowing it to effectively transfer heat away from its source and minimize heat penetration into insulated spaces. This quality ensures a stable and comfortable indoor environment, thereby reducing the need for excessive heating or cooling. Moreover, aluminum coils find extensive application in air conditioning and refrigeration systems, where they serve as the primary heat transfer medium. By efficiently absorbing and dissipating heat, these coils expedite the cooling process, resulting in reduced energy consumption and improved overall energy efficiency. Furthermore, the lightweight nature of aluminum makes it highly convenient for handling and installation in insulation systems. Its low weight provides flexibility and ease during manufacturing and transportation, leading to cost and energy savings. In addition, aluminum coils possess remarkable corrosion resistance, guaranteeing their durability and preventing the deterioration of insulation performance over time. This longevity ensures long-term energy efficiency as the insulation system remains effective without the need for frequent maintenance or replacement. In conclusion, aluminum coils significantly contribute to energy-efficient insulation through their effective heat conduction, facilitation of rapid cooling in air conditioning systems, reduced energy consumption, lightweight and easy handling, as well as long-lasting performance due to corrosion resistance. These qualities make aluminum coils the ideal choice for enhancing energy efficiency in insulation applications.

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- Oil removal effect is not good rolling oil remover oil extrusion is not complete, coiling in aluminum strip surface residual oil too much, after coiling because of oil coated on the aluminum coil inside played a supporting role in the beginning of aluminum roll edge round, with aluminum coil of diameter increases, the inner pressure increases.

- Q: i want to save some money on my electricity bill, and i heard that aluminum foil rejects the heat that goes through the windows, also does it work with the cold?

- looks like you got a grow your own lab. watch for unmarked van out side your house

- Q: Are there any limitations or drawbacks of using aluminum coils?

- There exist certain limitations and drawbacks regarding the utilization of aluminum coils. To begin with, one limitation is the higher cost of aluminum coils compared to alternative coil materials, such as copper. This disparity in cost can result in reduced cost-effectiveness, especially when large quantities of coils are necessary. Another drawback is that aluminum coils exhibit lower thermal conductivity in comparison to copper coils. Consequently, the transfer of heat may not be as efficient, ultimately impacting the overall system performance. In instances where heat transfer is of utmost importance, copper coils may be the preferred option. Furthermore, aluminum is more susceptible to corrosion in contrast to other metals. Although aluminum coils are typically coated or treated to enhance corrosion resistance, they can still be vulnerable to damage in harsh environments or if the coating is compromised. This can lead to diminished efficiency and a shorter lifespan for the coils. Moreover, aluminum coils may not be suitable for certain applications that require high strength or durability. Due to its relatively soft nature, aluminum may not effectively withstand heavy loads or extreme conditions as other materials would. Lastly, repairing or replacing aluminum coils can be more challenging compared to other coil types. The unique properties of aluminum necessitate the utilization of specialized tools and techniques, consequently adding to the overall complexity and cost of maintenance or repairs. In conclusion, while aluminum coils possess advantages, it is crucial to consider these limitations and drawbacks when selecting the appropriate coil material for a specific application.

Send your message to us

1050 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords