FRP Pultrusion Profiles - Anti-Corrosive FRP Gratings with Impact Resistance 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

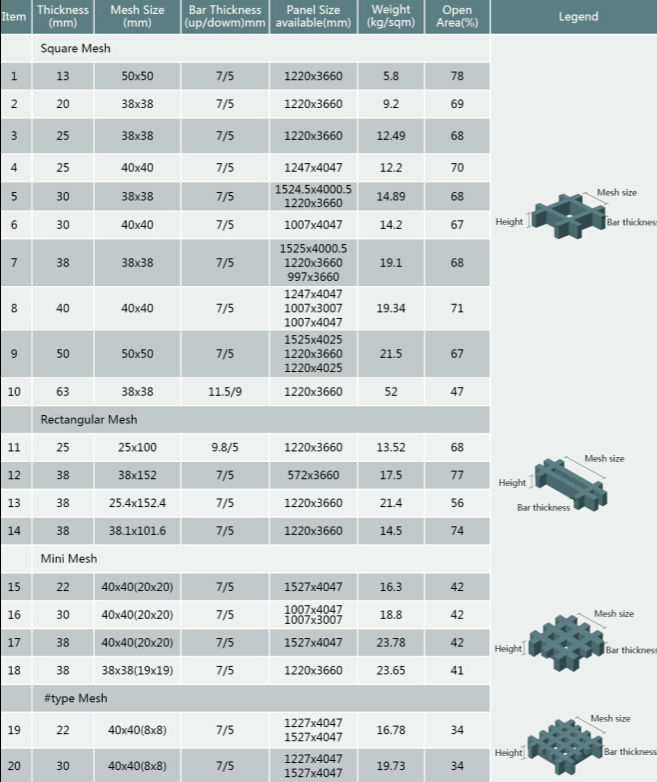

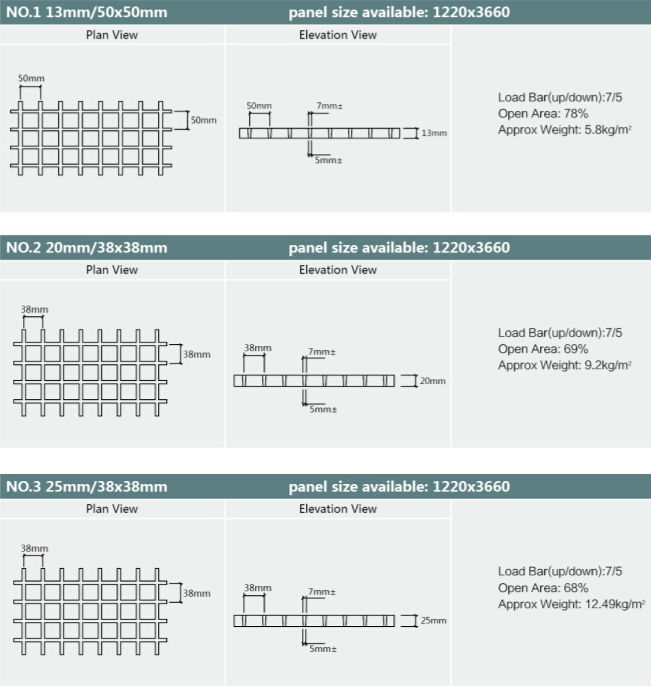

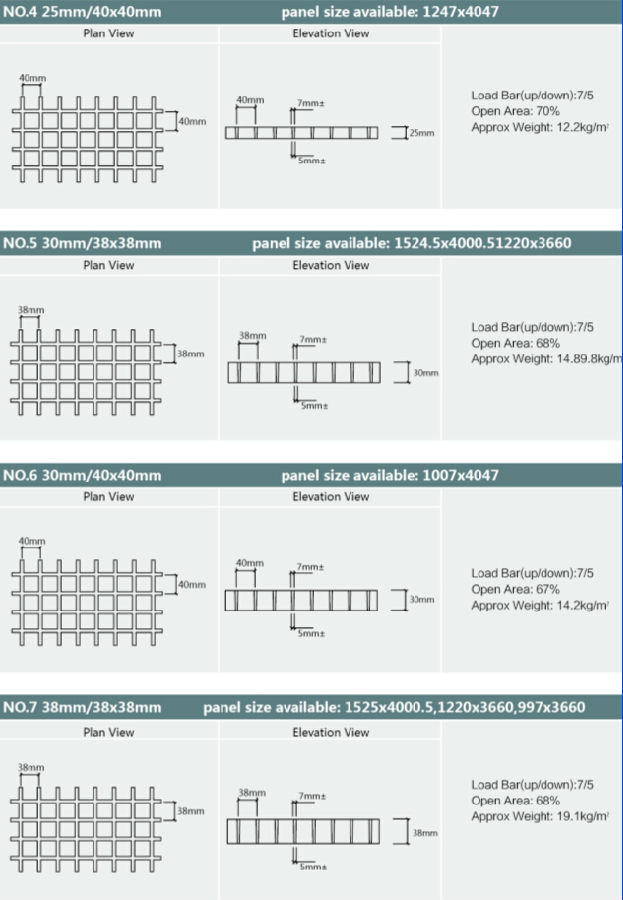

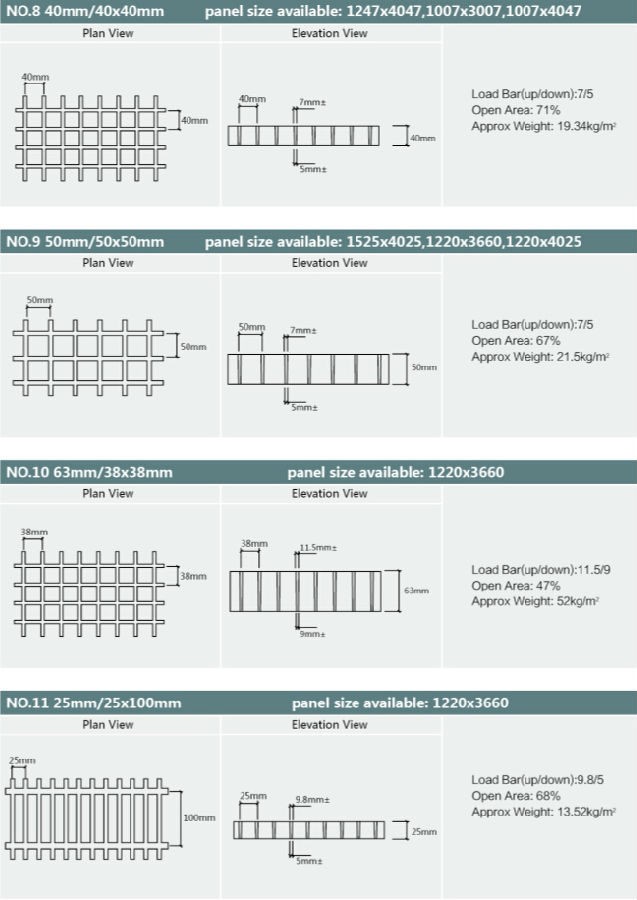

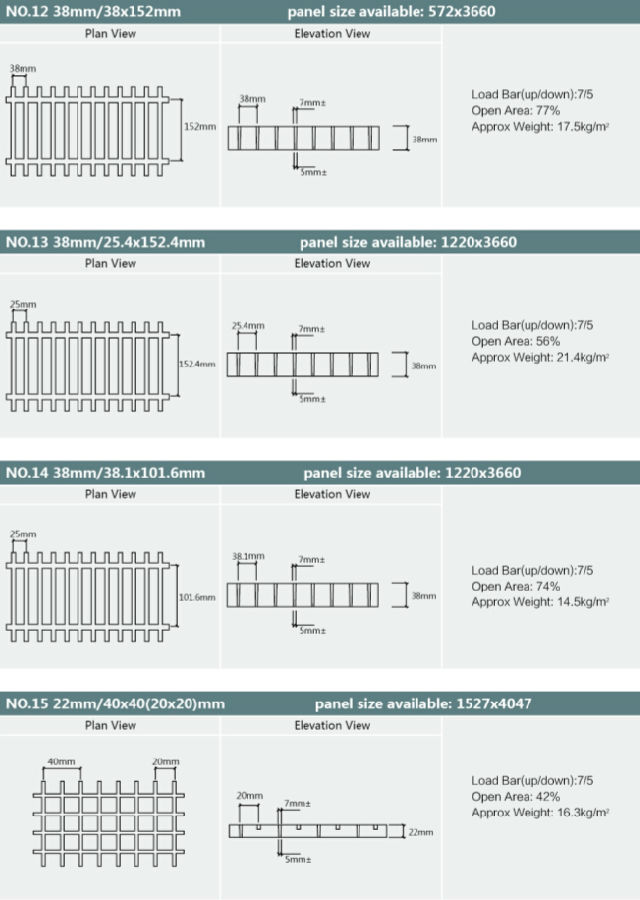

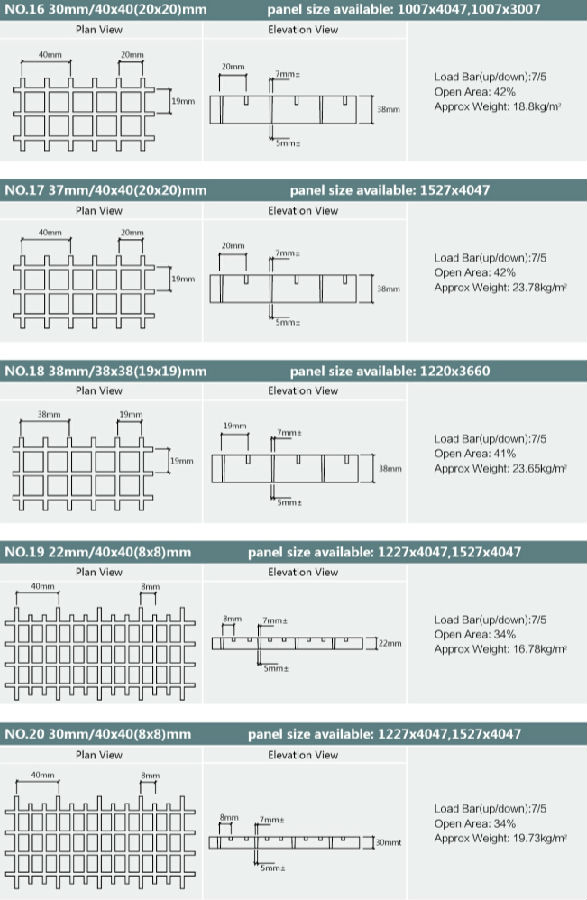

Moded Grating Sizes List:

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- FRP pultrusion profiles offer exceptional resistance against high winds and hurricanes. Combining the robustness of fiberglass with the longevity of polymers, FRP is a lightweight yet remarkably sturdy material that can endure severe weather conditions. Extensive testing has proven that FRP pultrusion profiles exhibit outstanding wind resistance properties. They possess a remarkable stiffness-to-weight ratio, enabling them to withstand the powerful forces generated by high winds without deformation or breakage. Additionally, the inherent flexibility of FRP permits it to absorb and distribute wind forces, minimizing the risk of damage. In the face of hurricanes, FRP pultrusion profiles have demonstrated their capability to withstand the intense winds and airborne debris associated with such extreme weather events. They have been successfully employed in various applications, including building facades, bridges, and utility poles, in areas prone to hurricanes. Moreover, FRP pultrusion profiles possess corrosion resistance, providing an extra advantage in withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or decay when exposed to moisture, making them even more suitable for these demanding weather conditions. Overall, with their exceptional strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications requiring resistance against high winds or hurricanes.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- Yes, FRP pultrusion profiles are generally resistant to alkalis.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

- Q: Are FRP Pultruded Shapes poisonous?

- The use of food grade resins, pultruded extrusions, is not toxic, and this can be applied to Waterworks

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- FRP pultrusion profiles possess inherent resistance against termites and other pests. Unlike traditional wood or metal materials, FRP profiles fail to serve as a food source for termites or any other pests. FRP comprises reinforced fibers and a polymer matrix, typically constructed from fiberglass and resin. These constituents lack appeal to pests and do not provide any nutritional value, thus rendering FRP profiles highly resistant to termite damage or infestation. The capability of withstanding pests is among the numerous benefits of employing FRP pultrusion profiles across diverse applications, particularly in outdoor or humid settings, where termites frequently thrive.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP pultrusion profiles can be used in infrastructure projects. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for applications in bridges, walkways, railings, and other structural components. They offer high strength-to-weight ratios and can be customized to meet specific project requirements. Additionally, FRP pultrusion profiles are non-conductive, making them suitable for electrical infrastructure projects.

- Q: Can FRP pultrusion profiles be used in the production of electrical busbars?

- FRP pultrusion profiles possess exceptional electrical insulation properties, a high strength-to-weight ratio, and resistance to corrosion, making them suitable for the manufacturing of electrical busbars. These profiles excel in electrical insulation, reducing the likelihood of electrical shock and short circuits when compared to conventional metal busbars. Furthermore, their superior strength-to-weight ratio allows for lightweight busbars capable of handling substantial electrical currents without compromising structural integrity. In addition, FRP pultrusion profiles demonstrate exceptional resistance to corrosion and chemicals, making them an ideal choice for harsh environments like chemical plants or outdoor installations. They remain free from rust and degradation, ensuring the longevity and reliability of the electrical busbars. Ultimately, FRP pultrusion profiles offer a cost-effective and efficient solution for the production of electrical busbars, providing improved electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP pultrusion profiles can be used in renewable energy projects. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them suitable for various applications in renewable energy projects. They can be used in the construction of wind turbine blades, solar panel frames, and structural supports for renewable energy infrastructure. Additionally, FRP pultrusion profiles can provide cost-effective solutions by reducing maintenance requirements and improving the overall performance of renewable energy systems.

- Q: Are FRP pultrusion profiles resistant to moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture. The manufacturing process of FRP pultrusion involves impregnating fiberglass reinforcements with a resin matrix, typically polyester, vinyl ester, or epoxy. These resins are inherently moisture-resistant, making FRP pultrusion profiles suitable for various applications that involve exposure to moisture or humid environments. Unlike traditional materials like wood or steel, FRP does not absorb water, which eliminates the risk of swelling, warping, or corrosion. This moisture resistance is particularly advantageous in applications such as construction, infrastructure, and marine industries, where the profiles may be exposed to rain, saltwater, or high humidity. Additionally, the resin matrix used in FRP pultrusion can be further enhanced with additives or coatings to provide even greater moisture resistance. For example, UV inhibitors can be added to protect against degradation caused by sunlight exposure. Fire-retardant coatings may also be applied to meet specific safety requirements. Overall, FRP pultrusion profiles offer excellent resistance to moisture, making them a durable and reliable choice for various applications where moisture exposure is a concern.

Send your message to us

FRP Pultrusion Profiles - Anti-Corrosive FRP Gratings with Impact Resistance 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords