FRP Pultrusion Profiles - Anti-Flammable FRP Pultruded Gratings with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

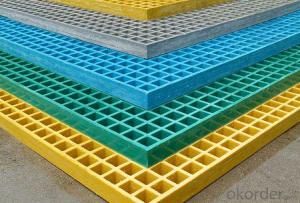

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

PICTURES

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to hail or impact damage. The combination of reinforcing fibers, such as carbon or glass, and a polymer resin matrix provides exceptional strength and durability to FRP pultrusions. These profiles have superior impact resistance compared to other materials like wood, steel, or aluminum. FRP pultrusion profiles are designed to withstand harsh environmental conditions, including hailstorms. The composite nature of FRP allows it to absorb and distribute impact energy, preventing the formation of cracks or fractures. This makes them an ideal choice for applications that require resistance to hail or impact damage, such as building facades, bridges, handrails, or utility poles. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, meaning they can withstand heavy impacts without compromising their structural integrity. They are also non-corrosive, which makes them immune to rust or degradation caused by hail or impact. In summary, FRP pultrusion profiles are highly resistant to hail or impact damage due to their composite construction and excellent strength-to-weight ratio. They provide a reliable and long-lasting solution for applications that require durability and resistance to harsh environmental conditions.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can definitely be used in architectural or decorative applications. FRP, which stands for Fiber Reinforced Polymer, is a composite material that combines strong fibers, such as glass or carbon, with a polymer resin matrix. This combination creates a lightweight, durable, and corrosion-resistant material that is ideal for various applications, including architecture and decoration. FRP pultrusion profiles can be manufactured in a wide range of shapes and sizes, making them highly versatile for architectural and decorative purposes. These profiles can be used to create aesthetically pleasing structures, such as columns, beams, and facades, that enhance the visual appeal of buildings. Additionally, FRP pultrusion profiles can be fabricated to mimic the appearance of other materials, such as wood or metal, allowing for the creation of decorative elements that blend seamlessly with the overall design. Furthermore, FRP pultrusion profiles offer several advantages over traditional materials commonly used in architecture and decoration. They are lightweight, which makes them easier to handle and install, reducing labor costs. They are also highly resistant to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Additionally, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, providing endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable option for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance ensures longevity and low maintenance. Whether it's for structural support or decorative embellishments, FRP pultrusion profiles offer an excellent choice for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP pultrusion profiles can be used in the automotive manufacturing industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used in various automotive applications including body panels, structural components, and interior trim.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

Send your message to us

FRP Pultrusion Profiles - Anti-Flammable FRP Pultruded Gratings with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords