FRP Pultrusion Profiles Molded Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

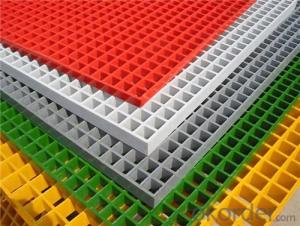

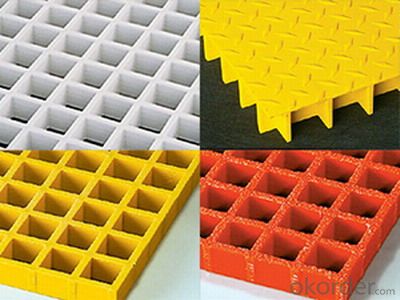

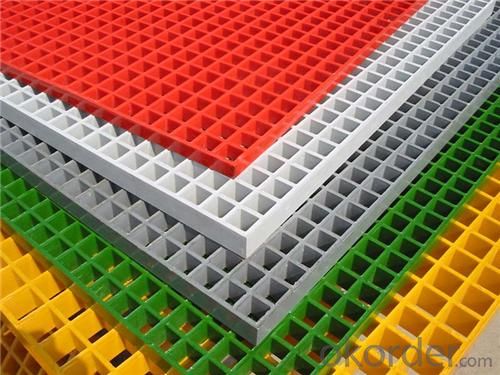

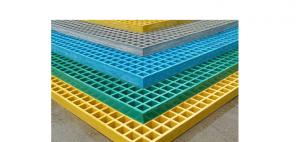

Brief Introduction of FRP Molded Gratings

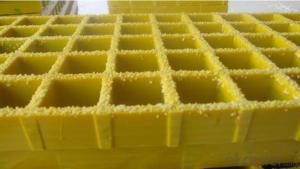

The product is a kind of structural plates which uses high-strength fiberglass roving as reinforcing material, thermosetting resin as the base and then is cast and formed on a special metal mold. It provides properties such as: light in weight, high in strength, corrosion resistance, fire resistance, solid and anti-skid. It is widely used in oil industry, power enrineering, sewage treatment, ocean survey as working floor, stair tread, trench cover, and the . It is an ideal loading frame on corrosion circumstances.

Product Performance of FRP Molded Gratings

1. Corrosion-resistance

2. Fire-resistance

3. Light in weight and high in strength

4. Ageing resistance

5. Designable

6. Safe and anti-skid

7. Insulation

Main Application of FRP Molded Gratings

Operation terrace off-shore oil rig Inspection rack

Stair tread Ground floor

Trench cover

Bridge sidewalk foot bridge

Equipment safety fence

Stair landing

Scaffold filling supporting

Decorating grid

Air grid, etc.

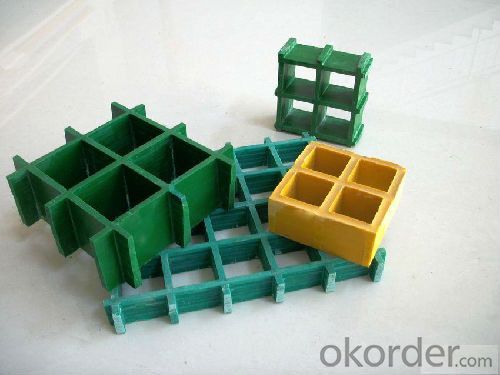

Specification of FRP Molded Gratings

Type | Panel size mm | Lattice size mm | Void ratio | Panel weight Kg |

AS/38.1 x38.1/25.4 | 1220 x 3660 x 25.4 | 38.1*38.1 | 69.9 | 64 |

AS/25.4 x101.6/25.4 | 1220 x 3660 x 25.4 | 25.4 x 101.6 | 63.9 | 73 |

AS/38.1 x38.1/38.1 | 1220 x 3660 x 38.1 | 38.1*38.1 | 70.0 | 92 |

AL/38.1 x38.1/38.1 | 1520 x 3960 x 38.1 | 38.1*38.1 | 70.0 | 114 |

AS/50.8 x50.8/50.8 | 1220 x 3660 x 50.8 | 50.8 x 50.8 | 77.8 | 101 |

AS/38.1 x152.4/38.1 | 1220 x 3660 x 38.1 | 38.1*152.4 | 72.6 | 87 |

AS/38.1 x152.4/38.1 | 579 x 3048 x 38.1 | 38.1 x 152.4 | 74.8 | 34 |

JS/340x40/25 | 1247 x 3087 x 25 | 40 x 40 | 72.3 | 46 |

JS/40 x40/40 | 1247 x 3087 x 40 | 40 x 40 | 72.3 | 73 |

ES/52 x52 /30 | 1000 x 4000 x 30 | 52 x 52 + 19 x 19 | 70.0 | 72 |

ES/52 x52 /50 | 1000 x 4000 x 50 | 52 x 52 + 19 x 19 | 73.3 | 108 |

GS/100 x 100 /25.4 | 117.5 x1480 x25.4 | 100 x 100 | 83.8 | 9 |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- The renewable energy and solar power industry can effectively utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several key characteristics that make them ideal for such applications. To begin with, the high strength-to-weight ratio of FRP pultrusion profiles is crucial in the renewable energy sector. They are lightweight yet strong, allowing them to withstand various environmental conditions while remaining cost-effective. Additionally, these profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments like solar power plants or wind farms. Moreover, FRP pultrusion profiles have outstanding electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Furthermore, these profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, ensuring their safety for use in electrical and magnetic fields associated with renewable energy systems. In conclusion, FRP pultrusion profiles provide a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in pharmaceutical manufacturing. The use of high-quality resins and fiberglass reinforcement in the manufacturing process makes FRP pultrusion profiles highly resistant to a wide range of chemicals, acids, and alkalis commonly used in pharmaceutical manufacturing. However, it is always advisable to consult with the manufacturer or supplier to ensure that the specific chemicals used in the manufacturing process are compatible with the FRP profiles.

- Q: What are the characteristics of FRP products?

- Good electrical performanceIt is a good insulating material used for making insulators. High dielectric protection can be maintained at high frequencies. Microwave permeability is good, and has been widely used in radome.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent corrosion resistance, high strength, and durability. These properties make them suitable for various applications in the water treatment industry. FRP pultrusion profiles can be used in the construction of water treatment tanks, pipes, and other infrastructure. They are resistant to chemicals, including the harsh chemicals often used in water treatment processes. This corrosion resistance ensures a longer lifespan for the equipment and reduces maintenance costs. Additionally, FRP pultrusion profiles have a high strength-to-weight ratio, making them ideal for applications that require lightweight yet strong materials. This allows for easier installation and transportation of water treatment equipment. Furthermore, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes to meet specific project requirements. This allows for customization and optimization of water treatment systems, ensuring efficient and effective water treatment processes. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the water treatment industry. They provide excellent corrosion resistance, high strength, and design flexibility, making them suitable for various applications in water treatment systems.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to wear and abrasion. The combination of the reinforcing fibers, typically glass or carbon, and the plastic resin matrix creates a material that is incredibly durable and can withstand heavy usage. The pultrusion process also ensures a homogeneous structure with fibers evenly distributed throughout the profile, further enhancing its resistance to wear and abrasion. Additionally, FRP pultrusion profiles can be engineered with specific additives or surface treatments to further enhance their resistance to wear and abrasion, making them suitable for a wide range of applications in various industries, such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in the production of electrical busbars?

- FRP pultrusion profiles possess exceptional electrical insulation properties, a high strength-to-weight ratio, and resistance to corrosion, making them suitable for the manufacturing of electrical busbars. These profiles excel in electrical insulation, reducing the likelihood of electrical shock and short circuits when compared to conventional metal busbars. Furthermore, their superior strength-to-weight ratio allows for lightweight busbars capable of handling substantial electrical currents without compromising structural integrity. In addition, FRP pultrusion profiles demonstrate exceptional resistance to corrosion and chemicals, making them an ideal choice for harsh environments like chemical plants or outdoor installations. They remain free from rust and degradation, ensuring the longevity and reliability of the electrical busbars. Ultimately, FRP pultrusion profiles offer a cost-effective and efficient solution for the production of electrical busbars, providing improved electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in food processing. Fiberglass reinforced plastic (FRP) is known for its excellent chemical resistance, making it suitable for various industrial applications, including the food processing industry. FRP pultrusion profiles are composed of a combination of resins and fiberglass reinforcements, which provide them with inherent resistance to a wide range of chemicals. FRP pultrusion profiles are typically resistant to acids, alkalis, solvents, and many other chemicals commonly found in food processing environments. This resistance ensures that the profiles will not corrode, degrade, or react with the chemicals, preserving their structural integrity over time. This makes FRP pultrusion profiles a reliable choice for equipment, structures, and components used in food processing facilities. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles can vary depending on the resin system used in their manufacturing. Different resins offer different levels of resistance to specific chemicals. Therefore, it is crucial to select the appropriate resin formulation that matches the specific chemical environment in the food processing industry. To ensure the compatibility of FRP pultrusion profiles with the chemicals used in food processing, it is advisable to consult with the manufacturer or supplier. They can provide detailed information on the chemical resistance properties of their FRP profiles and assist in selecting the most suitable materials for the specific application. Additionally, proper maintenance and regular cleaning practices should be implemented to ensure the longevity and continued chemical resistance of FRP pultrusion profiles in food processing environments.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. FRP pultrusion profiles offer several advantages that make them suitable for applications in this industry. Firstly, FRP pultrusion profiles are corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, such as saltwater, chemicals, and extreme temperatures. This makes them ideal for use in offshore platforms, pipelines, and other oil and gas facilities where corrosion can be a significant issue. Secondly, FRP pultrusion profiles have high strength-to-weight ratio. They are lightweight yet extremely strong, allowing for efficient installation, transportation, and handling. This is particularly beneficial in the oil and gas industry, where weight reduction is a crucial factor in improving operational efficiency and reducing costs. Thirdly, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them versatile for different applications in the oil and gas industry. Whether it is for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to fit the specific needs of each project. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. This is important in the oil and gas industry, where electrical safety is paramount. FRP profiles can provide insulation and prevent electrical conductivity, reducing the risk of accidents and ensuring the safety of personnel and equipment. Overall, FRP pultrusion profiles have proven to be reliable, durable, and cost-effective solutions for various applications in the oil and gas industry. Their corrosion resistance, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an attractive choice for this demanding industry.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent and can corrode many materials including metals. However, FRP (Fiber Reinforced Polymer) pultrusion profiles are made of composite materials that are specifically designed to be resistant to various corrosive substances, including nitric acid. The corrosion resistance of FRP pultrusion profiles can be attributed to the combination of their reinforcing fibers, such as fiberglass or carbon fiber, and the resin matrix that binds these fibers together. The resin matrix used in FRP profiles is typically a thermosetting polymer, such as polyester or epoxy, which provides a protective barrier against corrosive substances. Nitric acid is known to attack metals, causing corrosion and degradation. However, FRP pultrusion profiles offer excellent resistance to nitric acid due to the inert nature of the composite materials used. The reinforcing fibers in FRP profiles do not react with nitric acid, and the resin matrix acts as a barrier, preventing the acid from reaching and corroding the fibers. It is important to note that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the specific composition of the composite materials used and the concentration and temperature of the nitric acid. Therefore, it is always recommended to consult with the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

Send your message to us

FRP Pultrusion Profiles Molded Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords