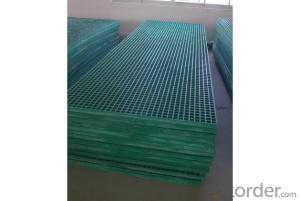

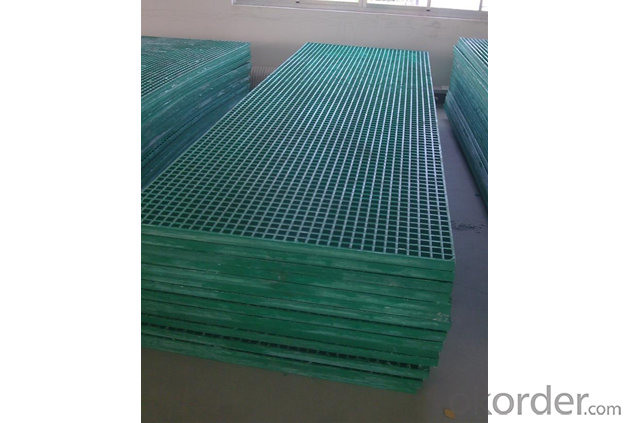

Fiberglass Plastic Walkway Grating with all kinds of Color/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

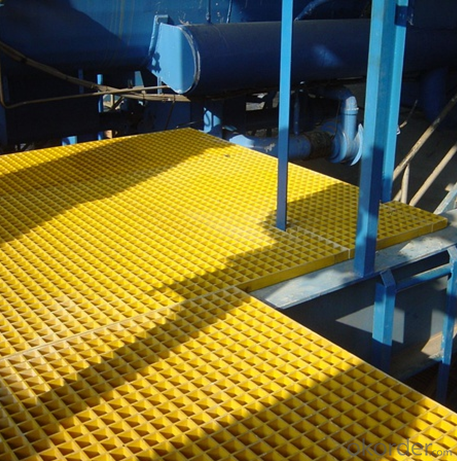

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

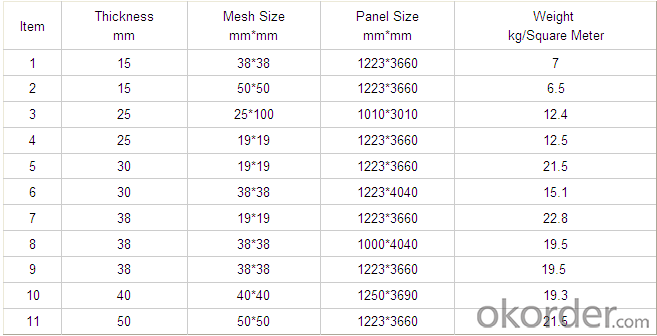

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to high winds and hurricanes. FRP is a composite material that combines the strength of fiberglass with the durability of polymers. This results in a lightweight yet incredibly strong material that can withstand extreme weather conditions. FRP pultrusion profiles have been extensively tested and have proven to have excellent wind resistance properties. They have a high stiffness-to-weight ratio, allowing them to withstand the forces exerted by high winds without bending or breaking. Additionally, the inherent flexibility of FRP allows it to absorb and distribute the forces exerted by wind, reducing the risk of damage. In the case of hurricanes, FRP pultrusion profiles have demonstrated their ability to withstand the strong winds and flying debris associated with these severe weather events. They have been used in various applications such as building facades, bridges, and utility poles in hurricane-prone areas, with great success. Furthermore, FRP pultrusion profiles are corrosion-resistant, which is another advantage when it comes to withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or rot when exposed to moisture, making them even more suitable for these challenging weather conditions. Overall, due to their high strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications where resistance to high winds or hurricanes is required.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for water treatment plant applications. These profiles can be used in various structural components like beams, columns, grating, and handrails, providing a cost-effective and long-lasting solution for the construction of water treatment plants.

- Q: How do FRP pultrusion profiles perform in heavy-load applications?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their exceptional performance in heavy-load applications. Due to their high strength-to-weight ratio, these profiles can withstand substantial loads without compromising structural integrity. The pultrusion process ensures that the fibers are uniformly distributed and aligned along the length of the profile, resulting in superior strength and stiffness. In heavy-load applications, FRP pultrusion profiles exhibit excellent load-bearing capabilities. They have a high modulus of elasticity, meaning they can resist deformation under heavy loads, ensuring long-term durability. These profiles also have a high ultimate tensile strength, allowing them to withstand extreme forces without breaking or deforming. Furthermore, FRP pultrusion profiles are corrosion-resistant, making them ideal for heavy-load applications in harsh environments. Unlike traditional materials like steel, FRP does not rust or corrode, ensuring a longer lifespan and reduced maintenance costs. Another advantage of FRP pultrusion profiles in heavy-load applications is their electrical insulation properties. They do not conduct electricity, making them suitable for environments where electrical conductivity is a concern. Additionally, FRP pultrusion profiles are lightweight compared to traditional materials like steel or concrete. This characteristic not only simplifies transportation and installation but also reduces overall project costs. In summary, FRP pultrusion profiles perform exceptionally well in heavy-load applications. Their high strength-to-weight ratio, excellent load-bearing capabilities, corrosion resistance, electrical insulation properties, and lightweight nature make them a preferred choice for various industries, including construction, infrastructure, marine, and transportation.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian tunnels. FRP profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for tunnel construction. Additionally, FRP profiles can be easily customized to meet specific design requirements and offer long-term cost savings due to their low maintenance needs.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP pultrusion profiles can be used in electrical or telecommunications applications. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent electrical insulation properties and are resistant to corrosion, making them suitable for use in electrical and telecommunications infrastructure. Additionally, their light weight, high strength, and design flexibility make them a desirable choice for applications such as cable trays, support structures, and enclosures in these industries.

- Q: Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Yes, FRP pultrusion profiles can be used in the construction of train or subway platforms. FRP (Fiber Reinforced Polymer) offers excellent strength, durability, and corrosion resistance, making it suitable for high-traffic areas like train or subway platforms. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for platform construction.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles are known for their durability, strength, and resistance to various environmental conditions, making them suitable for outdoor applications. These profiles are typically made of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet strong material. Outdoor signage often needs to withstand harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles have excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage can maintain its structural integrity and visual appeal over time. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and eye-catching outdoor signage. These profiles can be easily shaped, cut, and assembled, making them a versatile choice for signage applications. In summary, FRP pultrusion profiles can indeed be used in the construction of outdoor signage due to their durability, resistance to environmental conditions, and flexibility in design.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP pultrusion profiles can be used in the automotive manufacturing industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used in various automotive applications including body panels, structural components, and interior trim.

- Q: Are FRP pultrusion profiles resistant to chemicals used in power plants?

- Yes, FRP pultrusion profiles are highly resistant to chemicals commonly used in power plants. The composite materials used in their construction, such as fiberglass and resin, offer excellent resistance to corrosion and chemical attack. This makes FRP pultrusion profiles a durable and reliable choice for various applications in power plants, including structural components and equipment.

Send your message to us

Fiberglass Plastic Walkway Grating with all kinds of Color/Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords