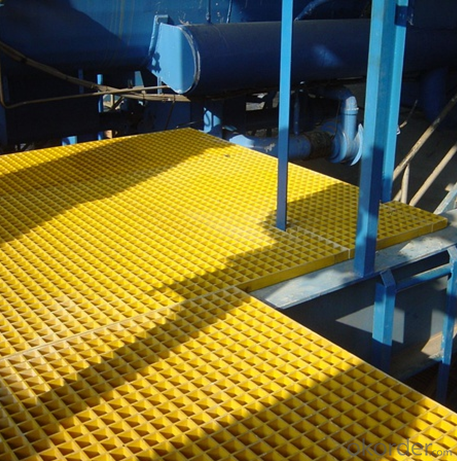

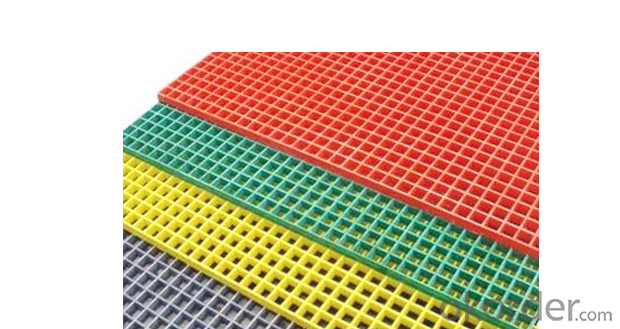

FRP Pultrusion Profiles:Fiberglass FRP Phenolic Molded & Pultruded Gratings with Modern Shape/All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

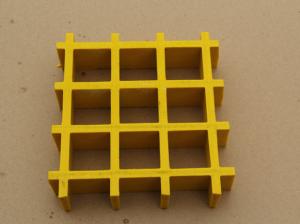

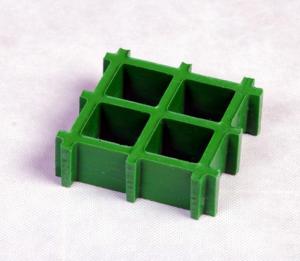

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Aging Resistance

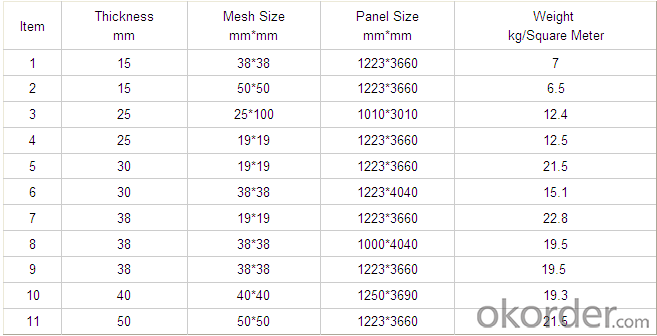

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of stadium seating. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, which is ideal for stadium seating where a large number of seats need to be installed. The lightweight nature of FRP profiles makes them easier to handle and install, reducing the time and effort required for construction. Secondly, FRP pultrusion profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications like stadium seating. They are not prone to rusting, rotting, or degradation from exposure to moisture, UV rays, or chemicals commonly found in stadiums. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety benefit, especially in areas where electrical wiring may be present. This reduces the risk of electric shocks or accidents that can occur with conductive materials. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in designing stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to match the aesthetic and functional requirements of the stadium. Lastly, FRP pultrusion profiles have a long service life with low maintenance requirements, reducing the overall cost of ownership for stadium seating. This makes them a cost-effective choice in the long run. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of stadium seating due to their lightweight, durable, non-conductive, customizable, and cost-effective nature.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- Yes, FRP pultrusion profiles can be used in the construction of railway sleepers. FRP (Fiber Reinforced Polymer) offers high strength, durability, and corrosion resistance, making it a suitable material for railway applications. The pultrusion process ensures consistent quality and allows for the customization of profiles to meet specific requirements. Additionally, FRP pultrusion profiles are lightweight and have excellent electrical insulation properties, making them an ideal choice for railway sleepers.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- Generally, FRP pultrusion profiles exhibit resistance to electrical arcing due to their composition of non-conductive materials such as fiberglass reinforced plastic. By not conducting electricity, these profiles prove to be an optimal choice when concerns arise regarding electrical arcing and conductivity. Nevertheless, it is crucial to acknowledge that the extent of their resistance to electrical arcing may differ based on the unique composition and design of the FRP pultrusion profiles. Therefore, it is advisable to consult the manufacturer or supplier of the profiles to ensure they meet the specific electrical resistance standards required for a given application.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

- Q: What is the tensile strength of FRP pultrusion profiles?

- The tensile strength of FRP (Fiber Reinforced Polymer) pultrusion profiles can vary depending on the specific type and composition of the materials used. Generally, FRP pultrusion profiles have high tensile strength, often exceeding that of traditional construction materials such as steel or aluminum. A typical tensile strength range for FRP pultrusion profiles can be anywhere from 300 MPa (megapascals) to 1500 MPa or higher. However, it is important to note that the tensile strength can be customized and engineered to meet specific project requirements by adjusting the reinforcement materials, fiber orientation, resin matrix, and manufacturing process. Therefore, it is advisable to consult with the manufacturer or supplier to obtain accurate and specific information regarding the tensile strength of a particular FRP pultrusion profile.

- Q: Are FRP pultrusion profiles impact resistant?

- FRP pultrusion profiles are widely recognized for their exceptional impact resistance. By combining reinforcing fibers like glass or carbon with a polymer matrix, they become intrinsically sturdy and long-lasting. The pultrusion process further bolsters their impact resistance by aligning the fibers in the direction of the load, providing optimal strength against impacts. Additionally, these profiles boast a remarkable strength-to-weight ratio, enabling them to withstand heavy impacts without significant damage or deformation. This characteristic makes them ideal for industries like construction, transportation, and infrastructure, where impact resistance is vital. Furthermore, FRP pultrusion profiles exhibit outstanding resistance to corrosion, chemicals, and UV radiation, enhancing their durability and long-term performance. Even in harsh environments, they maintain their impact resistance properties, making them the preferred choice for various sectors. Nonetheless, it is crucial to acknowledge that the impact resistance of FRP pultrusion profiles can vary depending on factors like design, composition, and manufacturing process. To ensure the profiles meet the desired impact resistance requirements for a specific application, it is advisable to consult with the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical insulation applications. FRP profiles offer excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high dielectric strength of FRP materials ensures that electrical currents are effectively contained within the desired pathways, preventing leakage and electrical hazards. Additionally, FRP profiles possess low electrical conductivity, reducing the risk of electrical shorts and improving overall safety in electrical insulation applications. The non-magnetic nature of FRP materials is also advantageous, as it eliminates the possibility of electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, corrosion-resistant, and have a long service life, making them a cost-effective and durable solution for electrical insulation applications.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to humidity and moisture. The combination of fiberglass reinforcement and a polymer resin matrix makes them inherently resistant to water absorption. Unlike traditional materials like wood or metal, FRP pultrusion profiles do not swell, warp, or corrode when exposed to moisture or high humidity levels. This resistance to moisture makes FRP pultrusions suitable for a wide range of applications in various industries, including construction, infrastructure, and marine environments. Additionally, FRP pultrusion profiles can be further enhanced with additional protective coatings or surface finishes to provide even greater resistance to moisture and humidity.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP pultrusion profiles have several desirable mechanical properties. They are known for their high strength-to-weight ratio, which makes them lightweight yet strong. Additionally, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for use in harsh environments. They also have good dimensional stability, meaning they do not easily warp or deform over time. Moreover, FRP pultrusion profiles have a high stiffness, providing structural integrity and minimizing deflection under load.

Send your message to us

FRP Pultrusion Profiles:Fiberglass FRP Phenolic Molded & Pultruded Gratings with Modern Shape/All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords