Aluminum Alloy Sheets - Anodized Aluminum Sheet for Traffic Sign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Anodized Aluminum Sheet for Traffic Sign Description:

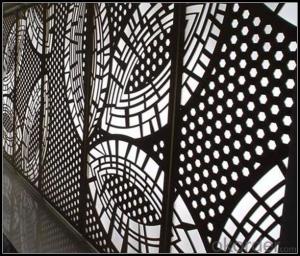

Hot Rolling Thick Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Anodized Aluminum Sheet for Traffic Sign :

1.Alloy no.:1050, 1060, 1070, 1000, 3003, 3004, 3005, 5052, 5005, 5083, 5086, 6061, 7075, etc.

2.Temper: all tempers

3.Passed the ISO9001 and SGS certificate

4.Have a wide product range of choices

5.Application: upholstery, lighting, solar reflection, elevator, household appliances, furniture and cabinet, architecture appearance,

car inside and outside decoration, etc

3. Anodized Aluminum Sheet for Traffic Sign Images:

4. Anodized Aluminum Sheet for Traffic Sign Specification:

Product | Alloy | Temper | Thickness | Width | End-Use |

(mm) | (mm) | ||||

Standard Sheets&Coils | 1100/1050/3003/6061 | O, H1X,H2X | 0.2~6.0 | 18~2400 | Commercial Application/ Marine/Insulation/Ducting |

5XXX,8XXX | H3X | ||||

Fin Stock | 1100/1200/8011 | H22,H24,H26 | 0.09~0.2 | 200~1220 | Heat Exchanger |

Closure Stock | 8011 | H16,H18 | 0.17~0.23 | 500~1550 | PP Caps, Bottle Lids |

Ceiling Stock | 1050/1100/3003 | H14,H16,H24,H26 | 0.4-1.0 | 600~1550 | Decoration, Ceiling |

5052/5005 | H22,H24,H32 | ||||

Can Stock | 3104 | H19 | 0.28~0.31 | 1000~1550 | Can Body |

Foil Stock | 1100/1200/8011 | F | 0.30~0.60 | 500~1550 | Re-rolling |

Lithographic Coil | 1050 | H18 | 0.10~0.30 | 650~1300 | PS Plate |

Coating Sheet | 1050/1100/3003 | O,H14,H22,H24, | 0.2~1.5 | 30~1550 | Color coating |

H26 | composite sheets & pipes |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are 101 aluminum sheets magnetic?

- No, 101 aluminum sheets are not magnetic. Aluminum is a non-magnetic metal, which means it does not attract or hold a magnetic charge.

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors such as the alloy composition, thickness, and intended application. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum sheets can typically withstand much higher temperatures without melting or deforming. For most commercially available aluminum alloys, the maximum temperature for continuous use ranges from 200-300 degrees Celsius (390-570 degrees Fahrenheit). Beyond this range, the material may start to experience reduced strength and increased susceptibility to deformation or damage. However, it is important to note that the specific maximum temperature limit for a particular aluminum sheet should be determined by consulting the manufacturer's specifications or conducting specific testing. Factors such as the presence of coatings or surface treatments, exposure to heat for extended periods, and thermal cycling can also affect the maximum temperature tolerance of aluminum sheets.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a lightweight and durable material that is commonly used in the food industry. It is non-toxic, non-reactive, and does not release any harmful chemicals when it comes into contact with food. Aluminum sheets are also easy to clean and maintain, making them a popular choice for food preparation surfaces in both commercial kitchens and home kitchens. Additionally, aluminum has excellent heat conductivity, allowing for even cooking and baking. However, it is important to note that aluminum can react with acidic or salty foods, causing a metallic taste. To prevent this, it is recommended to use a layer of parchment paper or silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- How many density units should be used in international units per kilogram of cubic meters, so that the unit of mass is kilogram? Weight = quality *9.81. The unit of cattle per kilogram is 5.4 kg of pure aluminum, and the weight is about 53 cows

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring. Aluminum sheet is primarily used for structural and decorative purposes due to its lightweight and corrosion-resistant properties. However, aluminum wire, which has different characteristics and is specifically manufactured for electrical applications, can be used for electrical wiring. Aluminum wire was commonly used in the past, but due to concerns about its conductivity, durability, and potential fire hazards, it has been largely replaced by copper wire in residential and commercial electrical installations. Copper wire is preferred for its superior conductivity and lower risk of developing loose connections or overheating.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Yes, aluminum sheets can be anodized without significantly affecting their dimensions. Anodizing is a surface treatment process that forms a protective layer on the aluminum, and it does not significantly alter the overall dimensions or shape of the sheet.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Mennen makes a line of plain old deodorant. They also make antiperspirants, though, so be sure you read the label.

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

- Q: What specific conditions are necessary for the storage and transportation of aluminum sheets to ensure their quality and safety?

- <p>Yes, there are special requirements for storing and transporting aluminum sheets. Aluminum sheets should be stored in a dry, cool place to prevent moisture and temperature extremes which can cause warping or corrosion. They should be stacked flat and evenly to avoid bending or denting. When transporting, aluminum sheets should be secured to prevent shifting during transit, which can lead to damage. Protective coverings may be used to shield the sheets from dirt, scratches, or other potential hazards. It's also crucial to handle the sheets carefully to avoid bending or denting, which can occur if they are not properly supported during transport.</p>

Send your message to us

Aluminum Alloy Sheets - Anodized Aluminum Sheet for Traffic Sign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords