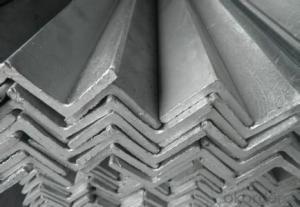

Angle Steel Hot Rolled High Quality ASTM Or GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Angle Steel Hot Rolled High Quality ASTM Or GB Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's SteelAngle Steel Hot Rolled High Quality ASTM Or GB Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the standard sizes of steel angles?

- The standard sizes of steel angles can vary depending on the region and industry, but there are some common sizes that are widely used. In general, steel angles come in equal leg and unequal leg sizes. For equal leg angles, the standard sizes range from 20x20mm to 200x200mm, with thicknesses ranging from 3mm to 26mm. Unequal leg angles typically have one leg longer than the other, and their standard sizes range from 25x16mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. These standard sizes are commonly used in construction, engineering, and manufacturing industries for various applications, such as structural supports, framing, and bracing. It's important to note that these sizes may vary depending on the specific requirements of a project or the standards set by the governing bodies within the industry.

- Q: Can steel angles be painted or finished for decorative purposes?

- Yes, steel angles can be painted or finished for decorative purposes. Steel angles, which are commonly used in construction and industrial applications, can be painted or finished to enhance their appearance and provide a decorative touch. Painting steel angles can help protect them from corrosion and rust while also allowing for customization to match the aesthetic requirements of the project. Additionally, finishes such as powder coating, electroplating, or galvanizing can be applied to steel angles to further enhance their appearance and durability. By painting or finishing steel angles, they can be seamlessly integrated into various architectural and design projects, making them both functional and visually appealing.

- Q: How do you join two steel angles together?

- One common method to join two steel angles together is by using bolts or screws. The angles can be aligned and holes can be drilled through both angles at the desired connection points. Then, bolts or screws can be inserted through the holes and tightened to securely fasten the angles together. Additionally, welding can also be used to join two steel angles together.

- Q: What does 50*50*5 angle mean?

- 50*50*5 angle means: the outer section of angle steel is 50mmx50mm, and the angle steel is 5mm.

- Q: Can steel angles be used as bracing elements?

- Yes, steel angles can be used as bracing elements. Steel angles are commonly used in construction and engineering projects for their strength and durability. They are often used to provide structural support and stability, including as bracing elements. Steel angles can be bolted or welded to other structural components to create a rigid and stable bracing system. Their L-shape design allows them to be easily attached to other members, providing additional strength and resistance against lateral forces such as wind or seismic loads. Overall, steel angles are a reliable choice for bracing elements in various applications, ranging from buildings and bridges to industrial structures.

- Q: Can steel angles be used for manufacturing vehicle frames?

- Yes, steel angles can be used for manufacturing vehicle frames. Steel angles are often used in construction and engineering due to their strength and ability to provide structural support. They can be easily welded or bolted together to create a sturdy and durable frame for vehicles. The angles can be cut and shaped to fit specific design requirements and can withstand the various stresses and forces that a vehicle frame may encounter during operation. Additionally, steel angles are readily available and cost-effective, making them a popular choice for manufacturing vehicle frames.

- Q: How do you determine the appropriate thickness of a steel angle for a specific application?

- To determine the appropriate thickness of a steel angle for a specific application, several factors need to be considered. These factors include the load-bearing requirements, the length and span of the angle, and the structural design codes and standards applicable to the specific application. By evaluating these factors, engineers can calculate the required moment of inertia and bending capacity, allowing them to select the appropriate thickness of the steel angle that will provide sufficient strength and structural integrity for the intended use.

- Q: Double angle steel rod in the corners of the roof steel why need to set the plate?

- Double angle truss rod set in which plate in the corners between the steel is mainly to increase its stiffness.

- Q: How do you calculate the load-bearing capacity of a steel angle?

- To calculate the load-bearing capacity of a steel angle, you need to consider factors such as the dimensions of the angle, the material properties of the steel, and the type of loading it will experience. The load-bearing capacity can be determined using engineering formulas or reference tables that take into account the angle's cross-sectional area, moment of inertia, and the yield strength of the steel. Additionally, structural design codes and standards should be consulted to ensure the calculated load-bearing capacity meets the required safety factors and regulations.

- Q: Can steel angles be used for structural purposes?

- Yes, steel angles can be used for structural purposes. Steel angles are commonly used in construction and engineering projects to provide structural support and stability. They are often used to reinforce and strengthen various structural components such as beams, columns, frames, and trusses. Steel angles are known for their high strength and durability, making them suitable for withstanding heavy loads and forces. They are versatile and can be easily welded, bolted, or screwed into place, allowing for easy installation and adaptation to different design requirements. Additionally, steel angles are available in various sizes, lengths, and thicknesses, making them suitable for a wide range of structural applications.

Send your message to us

Angle Steel Hot Rolled High Quality ASTM Or GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords