Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

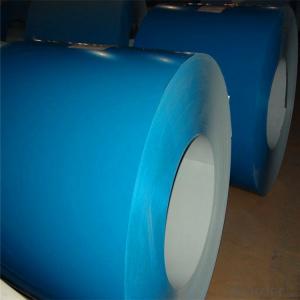

Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Description of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different methods of surface lapping for special steel?

- There are several different methods of surface lapping for special steel. These methods are used to achieve a high level of flatness and smoothness on the surface of the steel. One common method is called free abrasive lapping. In this method, a slurry containing abrasive particles is used to polish the surface of the steel. The slurry is typically applied to a rotating lap plate, which is then pressed against the steel surface. The abrasive particles remove material from the surface, resulting in a smoother and flatter surface. Another method is called fixed abrasive lapping. In this method, a rigid lap plate with abrasive particles embedded in it is used to polish the steel surface. The lap plate is typically made of a harder material than the steel being lapped. As the lap plate rotates and is pressed against the steel surface, the embedded abrasive particles remove material, resulting in a smoother surface. Chemical lapping is another method that can be used for special steel. In this method, a chemical solution is applied to the steel surface. The chemical solution reacts with the surface of the steel, dissolving and removing a thin layer of material. This method is often used when a high level of flatness is required. Ultrasonic lapping is a method that uses ultrasonic vibrations to enhance the lapping process. In this method, the steel surface is placed in contact with a bath of abrasive particles and a liquid medium. Ultrasonic vibrations are then applied to the liquid medium, causing the abrasive particles to vibrate and remove material from the surface of the steel. This method can be particularly effective for lapping hard and brittle materials. Overall, the different methods of surface lapping for special steel offer various approaches to achieve the desired level of flatness and smoothness. The selection of the method depends on factors such as the type of steel, the desired surface finish, and the specific requirements of the application.

- Q: Is special steel suitable for manufacturing precision components?

- Yes, special steel is indeed suitable for manufacturing precision components. Special steel possesses unique properties such as high strength, wear resistance, and excellent dimensional stability, making it ideal for producing components with precise and intricate designs. Additionally, its superior machinability and ability to withstand extreme conditions further enhance its suitability for manufacturing precision components.

- Q: How does special steel contribute to the pharmaceutical industry?

- Special steel plays a crucial role in the pharmaceutical industry by offering exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various equipment and components such as storage tanks, reactors, piping systems, and precision instruments. The unique properties of special steel ensure the integrity and purity of pharmaceutical products, prevent contamination, and enable efficient and safe production processes.

- Q: What are the different stamping grades of special steel?

- The different stamping grades of special steel include stainless steel, high-strength steel, tool steel, and alloy steel. Each grade has unique properties and characteristics that make them suitable for various stamping applications.

- Q: How is wear-resistant stainless steel used in the production of cutting tools?

- Wear-resistant stainless steel is used in the production of cutting tools because of its high strength, hardness, and corrosion resistance. This makes it suitable for applications where the tools need to withstand intense cutting forces and maintain sharpness over extended periods. The wear-resistant properties of stainless steel ensure that the cutting edges retain their sharpness and durability, resulting in efficient and reliable cutting performance.

- Q: What are the properties of maraging steel?

- Maraging steel is a type of high-strength steel known for its exceptional strength, toughness, and resistance to fatigue. It possesses a unique combination of properties such as high yield strength, excellent fracture toughness, and superior hardness. This steel also exhibits remarkable corrosion resistance and can withstand extreme temperatures. Additionally, maraging steel is highly weldable and machinable, making it suitable for a wide range of applications in industries such as aerospace, defense, and tooling.

- Q: How does special steel contribute to improving product resistance to environmental factors?

- Special steel contributes to improving product resistance to environmental factors in several ways. Firstly, special steel alloys often have enhanced corrosion resistance, protecting the product from damage caused by exposure to moisture, chemicals, and other corrosive substances present in the environment. Additionally, special steel can offer improved strength and durability, enabling the product to withstand harsh conditions such as extreme temperatures, high pressure, or mechanical stress. Furthermore, special steel can exhibit excellent fatigue resistance, ensuring that the product maintains its structural integrity even after prolonged exposure to cyclic loading or repetitive stress. Overall, the unique characteristics of special steel make it a valuable material for enhancing the resistance of products to various environmental factors, ultimately prolonging their lifespan and reducing maintenance costs.

- Q: How does special steel contribute to reducing product downtime due to repairs?

- Special steel contributes to reducing product downtime due to repairs by offering increased strength, durability, and resistance to wear and tear. With its unique properties, special steel can withstand harsh conditions and heavy usage, resulting in longer-lasting and more reliable products. This reduces the frequency and duration of repairs, minimizing the downtime experienced by the product and ultimately leading to increased productivity and efficiency.

- Q: How does the demand for special steel vary across different regions?

- The demand for special steel can vary significantly across different regions due to several factors. One of the key drivers of demand variation is the level of industrialization in a particular region. Developed regions with a strong manufacturing sector, such as North America, Europe, and East Asia, tend to have a higher demand for special steel as they rely heavily on it for various industrial applications. Another factor that influences demand variation is the presence of specific industries or sectors within a region. For example, regions with a significant automotive or aerospace industry will have a higher demand for special steel as these sectors require high-performance materials for the production of vehicles or aircraft. Moreover, the construction industry plays a crucial role in determining the demand for special steel. Regions experiencing rapid urbanization and infrastructure development, like Southeast Asia, the Middle East, and parts of Africa, have an increased demand for special steel for the construction of buildings, bridges, and other infrastructure projects. Additionally, the availability of raw materials and production capabilities within a region can affect the demand for special steel. Regions with ample access to iron ore, coal, and other necessary resources for steel production may have a higher demand for special steel as they can efficiently produce it. Lastly, economic trends and government policies also impact the demand for special steel. Regions with stable economic growth and favorable policies for industries that use special steel will likely experience higher demand. Conversely, regions facing economic downturns or restrictive trade policies may witness a decline in demand. In conclusion, the demand for special steel varies across different regions due to factors such as industrialization levels, specific industries present, construction activities, availability of raw materials, and economic trends. Understanding these variations is essential for steel manufacturers and suppliers to effectively target and cater to the diverse needs of different regions.

- Q: What are the potential health hazards associated with working with special steel?

- Working with special steel can pose potential health hazards due to the materials and processes involved. Some of the main health hazards associated with working with special steel include: 1. Inhalation of hazardous fumes: Special steels often contain various alloys and elements, such as chromium, nickel, and manganese, which can release toxic fumes when heated or welded. Prolonged exposure to these fumes can lead to respiratory issues, such as bronchitis, asthma, or even lung cancer. 2. Skin and eye irritation: Steelworking involves handling sharp edges, cutting tools, and abrasive materials, which can cause cuts, scratches, or puncture wounds. These injuries can become infected or lead to more serious conditions if not properly treated. Additionally, contact with certain alloys in special steel can irritate the skin or cause allergic reactions. Eye protection is crucial in this industry to prevent eye injuries from flying debris or sparks. 3. Noise-induced hearing loss: Steel manufacturing processes often involve heavy machinery, which generates high levels of noise. Prolonged exposure to such noise levels can lead to permanent hearing loss or other auditory issues. Workers should use appropriate hearing protection, such as earmuffs or earplugs, to minimize the risk. 4. Ergonomic hazards: Steelworking often requires repetitive movements, heavy lifting, or awkward postures, which can lead to musculoskeletal disorders, such as back pain, carpal tunnel syndrome, or tendonitis. Employers should implement proper ergonomic practices, including providing adjustable workstations, lifting aids, and regular breaks to prevent these hazards. 5. Thermal hazards: Special steel manufacturing processes involve high temperatures, such as welding or forging, which can lead to burns if proper protective clothing or equipment is not used. Exposure to extreme heat can also cause heat-related illnesses, including heat exhaustion or heat stroke. Adequate training, appropriate personal protective equipment (PPE), and regular breaks in cooler areas can help mitigate these risks. To protect workers from these potential health hazards, employers should implement proper safety protocols, including employee training, use of personal protective equipment, regular health monitoring, and maintaining a clean and well-ventilated work environment. Occupational health and safety regulations should be strictly followed to minimize the risks associated with working with special steel.

Send your message to us

Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords