Aluzinc Curragated Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

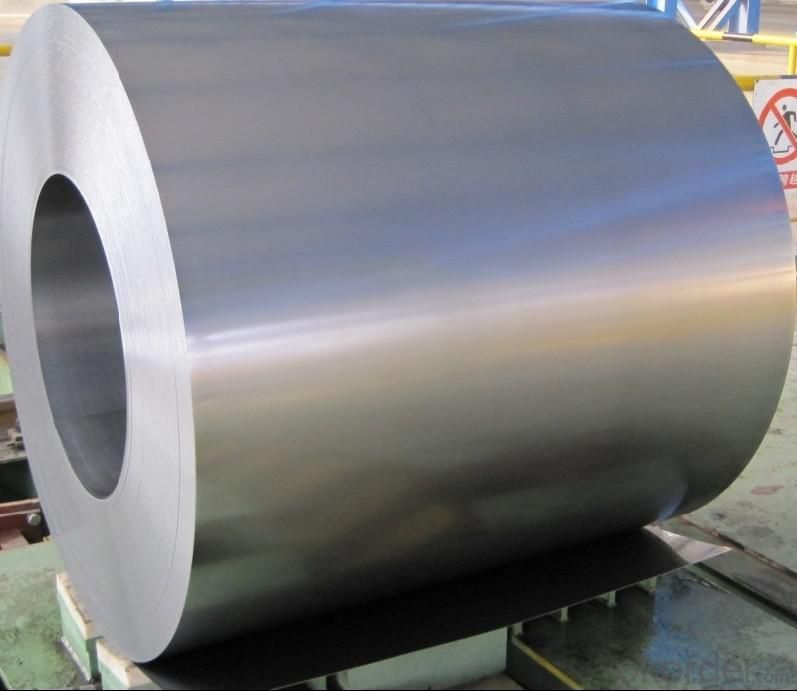

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can the steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets. Steel is a durable and sturdy material that is commonly used in the construction of cabinets and other storage solutions. Steel sheets can be easily fabricated and shaped into the desired size and design for cabinets, providing a strong and reliable storage solution. Additionally, steel is resistant to corrosion, making it suitable for storing various items and ensuring the longevity of the cabinets.

- Q: What is the average lifespan of galvanized steel sheets?

- The average lifespan of galvanized steel sheets can vary depending on several factors such as the environment, maintenance, and usage. However, in general, galvanized steel sheets have a lifespan of 20 to 50 years. This lifespan can be extended with proper care, regular inspection, and maintenance practices. Galvanized steel sheets are known for their durability and resistance to corrosion, which contributes to their relatively long lifespan. Nonetheless, factors such as exposure to harsh weather conditions, extreme temperatures, and corrosive substances can affect the longevity of galvanized steel sheets. Therefore, it is essential to consider these factors and implement appropriate maintenance measures to ensure the maximum lifespan of galvanized steel sheets.

- Q: What material can be replaced by 345D steel plate?

- The steel plate is divided into hot-rolled and cold-rolled parts according to rolling.

- Q: Are the steel sheets suitable for shipbuilding?

- Steel sheets are an excellent choice for shipbuilding due to their suitability and versatility. This durable material possesses exceptional properties for marine applications. Its high strength-to-weight ratio allows for the construction of sturdy vessels while maintaining a low overall weight. Furthermore, steel sheets have impressive tensile strength, ensuring the ship's structural integrity and resistance against external forces like waves, wind, and other factors. The corrosion-resistant nature of steel makes it particularly ideal for enduring the harsh saltwater environment. Additionally, its fire-resistant properties further enhance the safety of ships. Consequently, steel sheets are extensively utilized in shipbuilding and have demonstrated reliability and efficiency in constructing various types of vessels, including cargo ships, cruise liners, and naval warships.

- Q: What is the difference between a hot rolled and cold rolled galvanized steel sheet?

- The main difference between a hot rolled and cold rolled galvanized steel sheet is the process in which they are made. Hot rolled galvanized steel sheets are produced by rolling the steel at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold rolled galvanized steel sheets are processed at lower temperatures, allowing for a smoother surface finish and more precise dimensions. Additionally, the cold rolling process also tends to make the steel stronger and more durable.

- Q: Can steel sheets be used in packaging applications?

- Yes, steel sheets can be used in packaging applications. They are commonly used for packaging heavy or durable items that require strong protection, such as machinery parts or large appliances. Steel sheets offer superior strength and durability, making them suitable for ensuring the safe transportation and storage of various goods.

- Q: What are the different types of steel sheet surface coatings for corrosion resistance?

- There are several types of steel sheet surface coatings available for corrosion resistance, including galvanized coatings, zinc-rich coatings, aluminum coatings, and organic coatings such as paint or epoxy. Each coating offers unique benefits and application suitability depending on the specific requirements and environmental conditions.

- Q: What are the different grades of steel used for sheets?

- The different grades of steel used for sheets include low carbon steel, medium carbon steel, high carbon steel, stainless steel, and galvanized steel.

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel sheets offer durability, strength, and a sleek appearance, making them suitable for various architectural applications including cladding or facade systems. They can be customized in terms of color, finish, and shape, allowing for versatile design possibilities. Additionally, steel sheets provide weather and fire resistance, making them a reliable choice for exterior applications.

- Q: What are the applications of steel sheets in construction?

- Due to their exceptional strength, durability, and versatility, steel sheets find a wide range of applications in the construction industry. Some of the key uses of steel sheets in construction are: 1. Roofing and cladding: Steel sheets are commonly employed in both residential and commercial buildings for roofing and cladding purposes. They offer a long-lasting and weather-resistant solution, safeguarding the structure against the elements. 2. Structural components: Steel sheets are utilized to construct beams, columns, and trusses, which are essential structural components. The high strength-to-weight ratio of steel enables the creation of lightweight yet robust structures capable of withstanding heavy loads and seismic forces. 3. Flooring: In industrial buildings, warehouses, and factories, steel sheets are often used as flooring material. Their smooth surface facilitates easy cleaning and maintenance, and their strength and fire-resistant properties ensure a safe working environment. 4. Wall partitions: Steel sheets are commonly used in the construction of wall partitions due to their stability and sound insulation properties. They can be easily cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets find extensive use in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces enable efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are frequently integrated into concrete structures as reinforcement. This enhances the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In conclusion, steel sheets play a crucial role in construction for various applications, including roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an indispensable component in different construction projects, contributing to the overall safety, longevity, and functionality of buildings.

Send your message to us

Aluzinc Curragated Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords