Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

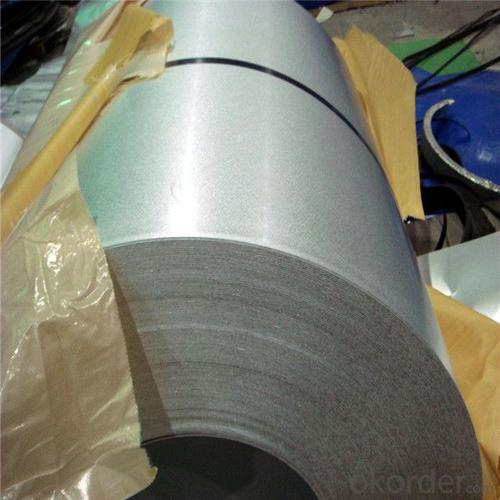

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and

specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon,

with excellent corrosion and heat resistance performance.

Strong, yet lightweight, Galvalume wont crack or peel when subjected to weather. Galvalume consists

of 55% aluminum, 43.4% zinc and 1.6% silicon over the base metal. This coating is applied during

a continuous hot-dip process. AZ40, AZ50, AZ55 and AZ60 translate to the coating thickness of .40,

.50, .55 and .60 ounces per square foot, respectively.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

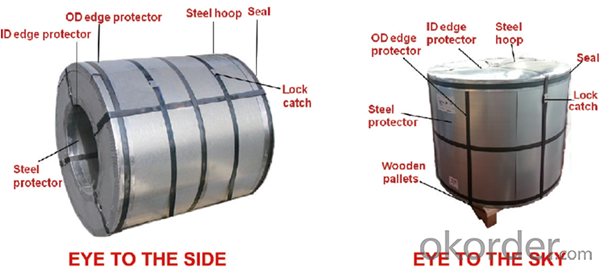

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q: How are steel coils transported and stored?

- Steel coils are typically transported using specialized trailers or railcars, ensuring secure and stable transportation. They are usually stored in warehouses or outdoor yards, stacked in neat rows using specialized equipment like coil racks or cradles. These storage methods help maximize space efficiency and prevent damage to the coils.

- Q: What are the common methods of painting steel coils?

- The common methods of painting steel coils include coil coating, spray painting, and electrostatic painting.

- Q: What are the different methods of cutting edge trimming for steel coils?

- There are several different methods of cutting edge trimming for steel coils, each with its own advantages and applications. Some of the most commonly used methods include: 1. Shearing: Shearing is a widely used method that involves cutting the edge of the steel coil using a pair of sharp blades. This method is relatively quick and efficient, making it suitable for high-volume production. However, shearing may result in some distortion or burrs along the cut edge. 2. Slitting: Slitting is a process where the steel coil is passed through a set of rotating circular blades that cut the coil into narrower strips. This method is commonly used when precise width control is required, such as in the production of narrow strips or slitting coils into multiple widths. 3. Laser cutting: Laser cutting is a highly precise method that uses a laser beam to cut through the steel coil. This method offers the advantage of producing clean and precise cuts without any distortion or burrs. Laser cutting is often used for complex or intricate shapes that require high accuracy. 4. Plasma cutting: Plasma cutting involves using a jet of ionized gas to cut through the steel coil. This method is particularly suitable for cutting thicker materials or for applications where high cutting speeds are required. Plasma cutting can produce clean and smooth cuts, although the edge may have a slight bevel. 5. Waterjet cutting: Waterjet cutting utilizes a high-pressure jet of water mixed with an abrasive material to cut through the steel coil. This method is highly versatile and can cut through a wide range of materials and thicknesses. Waterjet cutting is known for its ability to produce precise cuts without any heat-affected zone. 6. Sawing: Sawing is a traditional method that involves using a rotating saw blade to cut through the steel coil. This method is commonly used for thicker materials or when a rougher cut is acceptable. Sawing can be performed manually or using automated sawing machines. Each of these methods has its own advantages and considerations, and the choice of method depends on factors such as the required accuracy, production volume, material thickness, and desired edge quality.

- Q: How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks to create the structural framework and walls of the tanks. The coils are rolled and formed into the desired shape, providing strength and durability to store various agricultural materials such as grains, fertilizers, and liquids.

- Q: How are steel coils used in the production of steel cables?

- Steel coils are used in the production of steel cables by being uncoiled and straightened, then fed into a machine that twists and braids them together to create the cable.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel uses chromium in its mixture to thwart the affects of corrosion. General steel, or carbon steel, is generally almost completely iron and is used for far greater applications than stainless steel. Stainless steel is used mostly in kitchen appliances, utensils, etc... The best thing I can come up with is to find a way to measure the chromium content of the steel you are looking at. If it's around 3% chromium, it's probably standard steel. If it's somewhere between 10-15% chromium it's probably stainless steel (or even 4% plus). I can't tell you a fast and quick way to test the steel because from my research, it appears there are as many grades and allows of steel as there are uses for steel! There is one test I've seen for home testing surgical steel which is a higher grade stainless steel, that is to put scotch tape on one section of material then soak it in water for a 24 hour period, then let it air dry for 24 hours. You remove the tape and lightly polish the exposed areas to see if there was any discoloration or pitting on the exposed area. This test is mainly for surgical steel jewelry, however stainless steel is supposed to resist rusting more than standard steel, hence it might work for other steel types as well. You may have to read some of the other links below to get some other ideas on how you can test steel to see if it is stainless.

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- In 2.0*1000*C calculations, it is assumed that the formula for the length of 5T in this volume is 5000/ (2.0*1000*1000*7.93) = the total number of meters. First, the weight of one meter is calculated by dividing the total weight by the single weight, that is, the theoretical length of the volume

- Q: How are steel coils inspected for straightness?

- To ensure compliance with quality standards, steel coils undergo a variety of methods to inspect their straightness. Among these, visual inspection is commonly employed, wherein trained inspectors meticulously examine the coil's edges, surface, and overall shape for any visible flaws or irregularities that might indicate a lack of straightness. An alternative approach involves measuring the coil's straightness using precise instruments. This entails taking measurements at different points along the coil's length and comparing them to specified tolerances. Accurate assessment of the deviation from the desired straightness is achieved using techniques like laser measurements or straightness gauges. Moreover, certain coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to uncover any internal defects or stresses that may impact their straightness. These tests are capable of identifying hidden flaws that visual inspection alone may fail to detect. Additionally, some manufacturers employ automated inspection systems that leverage advanced technologies like computer vision or artificial intelligence. These systems swiftly scan the coil's surface and analyze it for any deviations from straightness, generating precise measurements and ensuring consistent quality. In summary, the inspection of steel coils to verify their straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods work together to identify any deviations from the specified straightness, ensuring that only coils meeting the required standards are utilized in various applications.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are used in the manufacturing of drivetrains as they provide the necessary strength and durability required for various components such as gears, shafts, and bearings. These coils are often shaped and machined to create specific drivetrain parts that can withstand the high pressures and forces involved in transferring power from the engine to the wheels.

Send your message to us

Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords