Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

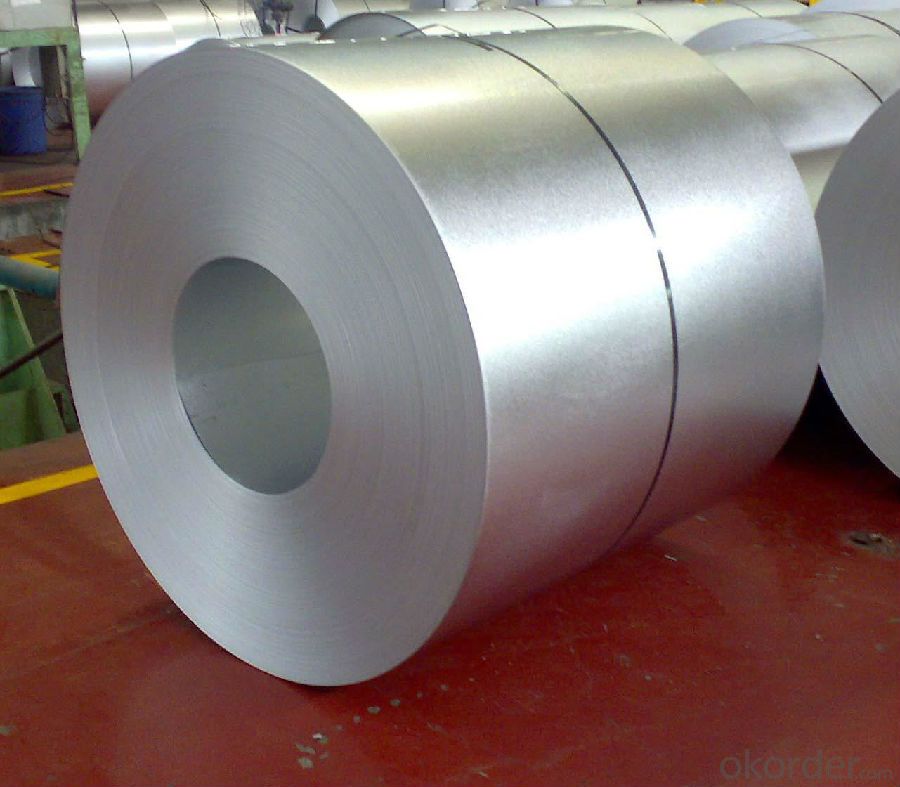

Hotdip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

2.Main Features of the Galvanized Steel Coil:

• Good formability

• Rust- proof ability

• Good visual effect

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

3. Aluzinc Steel Coil Images

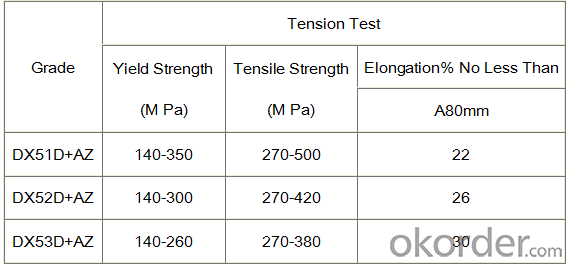

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Width: 914-1250mm

Inner Diameter: 508-610mm

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils can vary depending on the specific grade of steel used, but it typically ranges from 300 to 2,000 megapascals (MPa).

- Q: Can steel coils be coated with anti-microbial materials?

- Yes, steel coils can be coated with anti-microbial materials to provide protection against the growth of bacteria and other microorganisms.

- Q: What are the cost implications of using steel coils in manufacturing?

- The cost implications of incorporating steel coils into the manufacturing process can vary based on multiple factors. To begin with, the overall manufacturing expenses can be significantly affected by the cost of purchasing the steel coils themselves. Steel prices are influenced by various factors, including supply and demand, global market conditions, and any tariffs or trade regulations in place. Fluctuations in steel prices directly impact the cost of acquiring steel coils, which, in turn, affects the overall manufacturing cost. Furthermore, transportation costs can be influenced by the size and weight of the steel coils. Due to their heaviness and bulkiness, steel coils often incur higher shipping expenses as they require increased transportation resources. Additionally, shipping costs can be influenced by the distance between the steel supplier and the manufacturing facility. Moreover, the manufacturing costs can be influenced by the processing and transformation of steel coils into finished products. Depending on the desired end product, additional steps such as cutting, shaping, welding, or coating may be necessary. These supplementary processes require specialized machinery, skilled labor, and extra materials, all of which contribute to the overall manufacturing expenses. Considering the quality and durability of the steel coils is also essential. Although using high-quality steel coils may initially result in higher costs, it can lead to long-term savings by reducing the need for repairs or replacements. Furthermore, it is crucial to consider any regulatory or compliance requirements associated with the use of steel coils in manufacturing. Certain industries may have specific standards or certifications that need to be met, resulting in additional costs for testing, inspections, or compliance procedures. Lastly, it is important to acknowledge the potential cost savings that can be achieved through the utilization of steel coils in terms of efficiency and productivity. Steel coils are often preferred in manufacturing due to their strength, durability, and ease of fabrication. These characteristics can lead to improved production processes, reduced waste, and higher overall output, which can offset the initial cost of using steel coils. In conclusion, the cost implications of using steel coils in manufacturing are influenced by several factors, including steel prices, transportation costs, additional processing requirements, quality considerations, regulatory compliance, and potential productivity gains. A careful analysis and consideration of these factors are crucial for understanding the overall cost impact on manufacturing operations.

- Q: How to solve steel plate storage

- The warehouse temperature should be constant, prevent the occurrence of condensation, a horizontal steel coil to pile up, forced to pile up, in contact with each other at the coil not binding belt lock, steel roll room felt material, narrow roll on wide roll, roll on roll light. In order to facilitate the lifting, the steel coil and the wall should be kept a certain distance.

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- This Site Might Help You. RE: steel vs bronze acoustic guitar strings? i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- If it is calculated in accordance with the board, then his sales price should be 1*1*2*7.93*10=158.6 yuan / ZhangIf it is calculated according to the volume (assuming that the sales price is consistent), 0.9*1*2*7.93*10=142.7 yuan / ZhangSimilarly, a piece of stainless steel, if sold at the same price, leads to different prices. So in order to let both plate or rolling up to the same price, the price will be lower than the plate volume price, so the same with the price of the goods..The specific proportion of their conversion, can calculate the price of the goods in accordance with the principle of.

- Q: How are steel coils annealed for improved properties?

- Steel coils are annealed for improved properties through a process called annealing. This involves heating the steel coils to a specific temperature and then slowly cooling them to relieve internal stresses and create a more uniform and refined grain structure. This annealing process helps improve the steel's ductility, hardness, and overall strength, making it more suitable for various applications.

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils used in the energy sector can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in the energy sector range from 0.5mm to 5.0mm in thickness, with widths typically ranging from 600mm to 2000mm. The diameter of the coil can vary as well, with commonly used sizes ranging from 1000mm to 2200mm. These dimensions are chosen to ensure the coils can be easily transported, processed, and utilized in various energy sector applications such as power plants, oil and gas pipelines, and renewable energy projects. It is important to note that these dimensions are not fixed and can be customized based on specific project requirements.

- Q: who, when and where was dual phase steel invented?

- Looking okorder /... but I would note that this stuff seems an awful lot like the techniques that have been used for making high quality swords and cutting tools for thousands of years including the famed Damacas steel. In these, the steel is heated and slowly cooled (annealed) to produce the tough matrix, then the piece is reheated and quenched to produce the hard edge. What Dual-phase seems to do is bring the process to bulk manufacture.

- Q: What are the different methods of coil recoiling for narrow strip widths?

- There exists a variety of techniques for coil recoiling targeted at narrow strip widths. One technique, known as slitting and recoiling, entails slicing the wide coil into narrower strips and then rewinding them onto a smaller coil. This is typically accomplished using a slitting machine, which can make precise cuts to achieve the desired strip widths. Another approach, referred to as edge trimming and recoiling, involves trimming the edges of the wide coil to generate narrower strips. The remaining material is then rewound onto a smaller coil. This method is commonly employed when the coil edges are damaged or uneven and need to be removed before recoiling. Furthermore, there is a method called tension recoiling. In this process, the wide coil is threaded through a series of tensioning devices that aid in achieving the desired strip widths. The tensioning devices can apply controlled pressure to the coil edges, enabling precise recoiling of narrow strips. Additionally, some companies opt to employ laser cutting technology for coil recoiling. This technique entails using a laser beam to slice the wide coil into narrow strips, which are then rewound onto a smaller coil. Laser cutting offers exceptional precision and accuracy, making it an ideal choice for narrow strip widths. In summary, the various methods of coil recoiling for narrow strip widths consist of slitting and recoiling, edge trimming and recoiling, tension recoiling, and laser cutting. Each approach possesses its own merits and is selected based on the specific requirements and capabilities of the manufacturing process.

Send your message to us

Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords