Aluminum Zinc Rolled Coil for Steel Roof Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

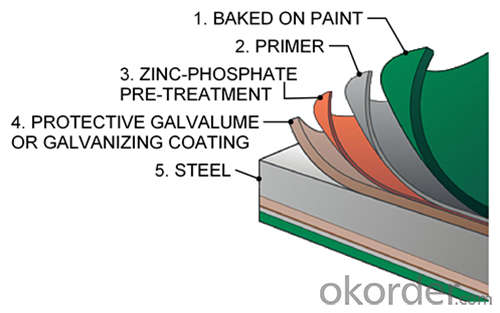

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | 3 Layer Standard seaworthy export packing: Inside is kraft paper ,water plastic film in the middle Outside GI steel sheet to be covered by steel strips with lock inner coil sleeve. |

Main Feature of Aluminum Zinc Rolled Coil

Corrosion resistance

Weather resistance

Long working life

Good formability

Applications of Aluminum Zinc Rolled Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Aluminum zinc rolled coil images

FAQ of Aluminum Zinc Rolled Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different coil packaging methods used for steel coils?

- There are several coil packaging methods that are commonly used for steel coils. These methods are designed to ensure the protection and safe transportation of steel coils, as well as to optimize storage space. Some of the different coil packaging methods used for steel coils include: 1. Strapping: This method involves securing the steel coils with metal or plastic straps. Strapping provides stability and prevents the coils from unrolling or shifting during transportation. It is commonly used for smaller coils or when additional packaging methods are also employed. 2. Stretch wrapping: Stretch wrapping involves using a stretch film to tightly wrap the steel coils. This method provides excellent protection against dust, moisture, and other contaminants. It also helps to keep the coils tightly bound together and prevents them from moving during handling and transportation. 3. Steel banding: Steel banding is a method that involves using steel bands or straps to secure the coils. This packaging method provides superior strength and durability. Steel banding is commonly used for larger and heavier steel coils that require extra reinforcement. 4. Wooden crating: Wooden crates are often used for packaging steel coils that are particularly large or heavy. The coils are placed within a wooden crate, which provides enhanced protection against impacts, moisture, and other external factors. Wooden crating is typically utilized for long-distance transportation or for coils that need to be stored for extended periods. 5. Coil saddles: Coil saddles are specialized devices that are used to package steel coils. These devices are designed to securely hold the coils in place and prevent them from rolling or moving. Coil saddles are commonly used for large coils that cannot be easily strapped or wrapped. 6. Paper interleaving: Paper interleaving involves placing sheets of paper between each layer of steel coils. This method helps to prevent damage caused by friction between the coils. Paper interleaving is often used for coils that have a high surface finish or are susceptible to scratching. Each of these coil packaging methods offers distinct advantages and is chosen based on factors such as the size and weight of the steel coils, transportation requirements, and the desired level of protection. By employing these packaging methods, steel coil manufacturers and distributors can ensure that their products arrive safely and in optimal condition at their destination.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that prevents damage and ensures their integrity. One common method is to stack the coils in a horizontal position. This helps distribute the weight evenly across the coils, minimizing the risk of deformation or damage. In addition, wooden or steel dunnage is often placed between each layer of coils to provide support and prevent them from shifting during storage or transportation. To further protect the coils from damage, they are often stored indoors or in covered areas to shield them from exposure to the elements. This helps prevent rusting or corrosion, which can compromise the quality of the steel. If outdoor storage is necessary, the coils may be covered with weather-resistant tarps or protective coatings to minimize the impact of rain, snow, or sunlight. Furthermore, it is important to consider the stacking height to prevent excessive pressure on the lower coils. To avoid damage, coils are typically stacked in a way that ensures the weight from the upper layers is distributed evenly across the lower ones. This can include using specialized stacking equipment or racks designed to handle the weight and dimensions of the coils. Overall, proper storage of steel coils involves careful consideration of weight distribution, protection from the elements, and minimizing contact between coils to prevent damage and maintain their quality.

- Q: How are steel coils used in the manufacturing of suspension arms?

- Steel coils are used in the manufacturing of suspension arms as they provide the necessary strength and flexibility to absorb shocks and vibrations, ensuring a smooth ride. These coils, known as coil springs, are typically mounted between the suspension arm and the vehicle's chassis, supporting the weight of the vehicle and allowing for controlled movement and suspension travel. By compressing and expanding, steel coils help absorb the impact of bumps and uneven road surfaces, providing stability and improving overall handling and comfort.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components as they serve as the primary raw material for producing various parts such as car bodies, chassis, and engine components. The coils are processed through a series of manufacturing techniques, including cutting, shaping, and welding, to transform them into specific automotive components. The high strength and durability of steel make it an ideal choice for these applications, ensuring the structural integrity and safety of the final automotive products.

- Q: Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- In all my experience as a farrier steel toes have neither helped nor caused any problem. I would be a vary rare case that the horse would be able to collapse the steel and with that much force the steel bending would be the last of your problems because your foot would have been completely destroyed without it. I agree with being alert a nd trying to get your feet out of the way. The few times i've been hurt the horse has chopped down toe first on the arch of my foot high above where there steel is any way. I've oddly enough never had a problem with getting my toes stepped on it really doen't seem to hurt if they land flat footed.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide high strength and durability, making them ideal for absorbing impact energy and protecting occupants in case of a collision. The coils are typically shaped and formed into specific components of the crash structure, such as side sills or front rails, which are then integrated into the vehicle's frame. This ensures that the vehicle has the necessary rigidity and structural integrity to withstand and mitigate the forces generated during a crash, thereby enhancing the safety of the occupants.

Send your message to us

Aluminum Zinc Rolled Coil for Steel Roof Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords