Prepainted Aluminum Zinc Rolled Coil for Construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminum Zinc Rolled Coil for Construction roof

Description of Prepainted Aluminum Zinc Rolled Coil for Construction roof

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Aluminum Zinc Rolled Coil for Construction roof

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Aluminum Zinc Rolled Coil for Construction roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

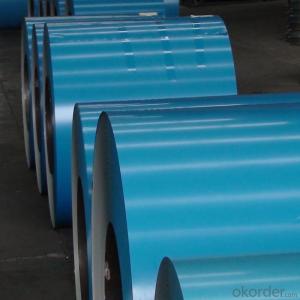

Prepainted Aluminum Zinc Rolled Coil for Construction roof Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction roof

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

Mechanical Properties | ||||||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % | |||

SGCC(DX51D+Z) | ≥205 | ≥270 | - | |||

SGCD(DX53D+Z) | - | ≥270 | 38 | |||

SGCE(DX54D+Z) | - | ≥270 | 40 | |||

DX56D+Z | - | ≥270 | 42 | |||

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction roof

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: My neighbor who has an older model mustang installed a steel clutch in it and has blown 4 transmissions as a result.Can any mechanic explain why a steel clutch would kill transmissions? What other modifications would the car need in order to prevent this?

- First of all it's not really a steel clutch..it is called a sintered iron clutch disk... a sintered iron clutch has a very aggressive amount of friction and is generally only used in racing application because of this...also it is ushually a non sprung disk. all of these factors = a very abrupt ingagement of the clutch which will shock the driveline very badly...say he's making 400hp and has really sticky tires..there is bound to be a weak link between the engine and the tires, in a factory driveline this would probably have been the clutch(it would slip) but since he has upgraded it he has now found the next weekest llink..in this case the transmission, he either needs to look into a beefier box or not launch the car so hard.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- Jet gasoline definitely does get warm sufficient to soften the engines (the cores of that are created from titanium alloy, not steel). in actuality, jet engines could be in particular designed as a fashion to not soften below popular working situations. As for the engines vaporizing it incredibly is extremely not likely. They probable have been pulverized via the impact forces and the debris then melted interior the hearth.

- Q: At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q: How are steel coils processed for stamping or forming?

- Steel coils are processed for stamping or forming through a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they are fed into a stamping or forming machine, where the desired shape or pattern is formed by applying pressure. After the stamping or forming process, the excess material is trimmed or cut off, and the finished parts are inspected for quality.

- Q: How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they are processed and shaped into various structural components like beams, plates, and girders. These coils are first uncoiled and then cut, rolled, and welded to create the required bridge sections. The high strength and durability of steel make it an ideal material for bridges, and the use of steel coils allows for efficient and precise manufacturing of these vital infrastructure elements.

- Q: What is future prospect of these steel structures, are they really weather proof like everyone believes??

- Yes okorder /

- Q: What are the different types of steel coil cutting tools?

- In the market, one can find a variety of steel coil cutting tools. These tools have been specifically designed to efficiently and accurately cut steel coils. Some of the commonly used types of steel coil cutting tools include: 1. Slitting shears: These shears are widely utilized to cut steel coils into narrow strips. Equipped with multiple blades, slitting shears offer clean and precise cuts without causing any damage to the material. They are typically employed in high-volume production and are capable of handling different thicknesses of steel coils. 2. Rotary shears: Another commonly used cutting tool for steel coils is the rotary shear. These shears consist of rotating blades that shear through the material as it passes through them. Rotary shears are perfect for cutting medium to thick steel coils and are known for their high cutting speed and accuracy. 3. Guillotine shears: Guillotine shears are heavy-duty cutting tools that can handle thick steel coils. They operate by exerting a downward force to cut through the material in one clean stroke. Renowned for their power and precision, guillotine shears are suitable for cutting large volumes of steel coils. 4. Laser cutting machines: Advanced cutting tools like laser cutting machines employ a high-powered laser beam to cut through steel coils. These machines offer precise and intricate cuts with minimal heat distortion. Laser cutting machines are ideal for cutting complex shapes and patterns on steel coils. 5. Water jet cutting machines: Water jet cutting machines utilize a high-pressure stream of water mixed with abrasive particles to cut through steel coils. This method provides high accuracy and does not generate heat, making it suitable for cutting heat-sensitive materials. Water jet cutting machines can cut through various thicknesses of steel coils and produce smooth edges. Each type of steel coil cutting tool has its own advantages and is suitable for different applications. The choice of tool depends on factors such as the thickness of the steel coil, required precision, production volume, and budget.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through visual examination, measuring thickness and width, and conducting various tests such as bend tests and surface inspections.

- Q: How are steel coils inspected for surface finish using profilometry?

- Steel coils are inspected for surface finish using profilometry by measuring the surface topography using a profilometer. The profilometer scans the surface of the steel coil and records the deviations from the ideal surface. This data is then used to determine the roughness, waviness, and other surface parameters of the steel coil, providing a quantitative assessment of its surface finish quality.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

Send your message to us

Prepainted Aluminum Zinc Rolled Coil for Construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords