Aluminum Zinc Rolled Coil for Steel Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

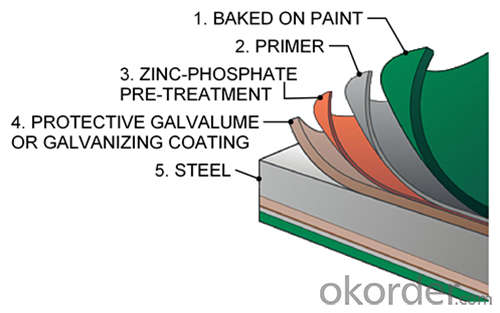

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | 3 Layer Standard seaworthy export packing: Inside is kraft paper ,water plastic film in the middle Outside GI steel sheet to be covered by steel strips with lock inner coil sleeve. |

Main Feature of Aluminum Zinc Rolled Coil

Corrosion resistance

Weather resistance

Long working life

Good formability

Applications of Aluminum Zinc Rolled Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Aluminum zinc rolled coil images

FAQ of Aluminum Zinc Rolled Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners by being processed into flat strips or wires, which are then cut, shaped, and threaded to create various types of fasteners such as screws, bolts, and nuts. The coils provide a continuous supply of steel material that is easily manipulable and can be efficiently transformed into the desired shape and size for fastener production.

- Q: At what temperature does steel start to warp or soften.

- Steel will only warp due to temperature under two conditions: 1. It is not heated evenly - in this case, the hotter parts will expand more than the cooler parts. 2. There are internal stresses in the steel (often from welding or cold-working - as an example, an I-beam or C-channel is usually hot worked, but some cold work can happen, so they can sometimes warp if you heat them ). This means that the steel won't warp due to temp if it's not 1 or 2. However, it could soften and fail if it has a load on it. As for softening, it really depends on what steel alloy you're looking at. Some steels (mainly the expensive alloys) don't really change until above 400 C (750 F), but mild steel really starts to weaken around 150-200 C (300-400 F) Rajashekhar has a point when it comes to forging. Steel isn't really soft enough to forge properly until above 1000C (1830 F), but if you're worried about using steel in a higher temp situation (like around a blast furnace or industrial oven), then make sure you choose a steel that has been rated to work at that temp.

- Q: What are the different methods of oiling steel coils?

- There are several methods of oiling steel coils, including applying oil by roll coating, using a spray system, or immersing the coils in an oil bath.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications across various industries, including automotive, construction, manufacturing, and appliance sectors. They are commonly used in the production of automobiles, machinery, and infrastructure components like bridges and buildings. Additionally, steel coils are utilized in the manufacturing of household appliances, such as refrigerators and washing machines. Their versatility, strength, and durability make steel coils a crucial material for many industrial applications.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes, they'll be marked HSS, High Speed Steel.

- Q: What are the different surface finishes of steel coils?

- The different surface finishes of steel coils include mill finish, galvanized finish, painted finish, and coated finish.

- Q: What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils offer superior strength and durability, making them suitable for various applications in industries such as construction, automotive, and manufacturing. Secondly, steel coils have excellent resistance to corrosion, ensuring longevity and reducing maintenance costs. Additionally, steel coils can be easily shaped or formed into different sizes and shapes, providing flexibility in design and manufacturing processes. Lastly, steel coils are recyclable, making them an environmentally friendly choice and contributing to sustainable practices.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials. This coating process enhances the electrical conductivity of the steel coils and allows them to conduct electricity efficiently.

- Q: How are steel coils used in the production of furniture components?

- Due to their strength, durability, and versatility, steel coils are frequently utilized in the manufacturing of furniture components. These coils, crafted from high-quality steel, undergo a process of uncoiling before being fed into a machine known as a stamping press. Within the stamping press, a die is employed to shape and cut the steel coil into various components necessary for furniture production, such as chair frames, table legs, or brackets. The utilization of steel coils facilitates the mass production of furniture components with uniform dimensions and exceptional accuracy. The robustness of steel guarantees that these components can withstand heavy loads, providing stability to the furniture. Additionally, steel coils possess the ability to be effortlessly molded into diverse shapes and sizes, enabling the creation of a vast array of furniture designs. Furthermore, steel coils are frequently subjected to protective treatments or coatings, such as paints or galvanization, in order to enhance their resistance to corrosion, moisture, and wear. This ensures that the furniture components possess a longer lifespan and retain their aesthetic appeal over time. In conclusion, the presence of steel coils plays a vital role in the production of furniture components, as they offer strength, durability, and versatility. They enable the mass production of precise and consistent components, while their protective coatings guarantee the durability and quality of the final furniture products.

- Q: What are the different types of corrosion protection for steel coils?

- There are various types of corrosion protection methods for steel coils. Some common ones include galvanization, which involves coating the steel with a layer of zinc; painting or coating the steel with corrosion-resistant materials such as epoxy or polyurethane; and applying a protective film or oil to create a barrier against moisture and corrosive elements. Additionally, using corrosion inhibitors in the form of chemicals or additives can also provide protection against corrosion. Ultimately, the choice of corrosion protection method depends on factors such as the expected exposure conditions and the desired level of protection.

Send your message to us

Aluminum Zinc Rolled Coil for Steel Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords