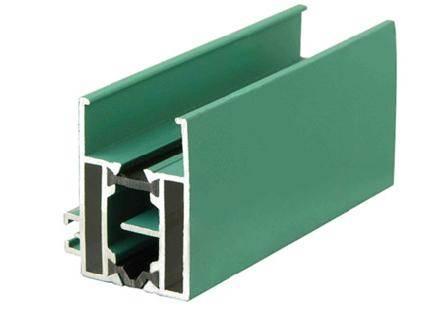

Aluminum Windows Profiles - Heat Insulation Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder Coating Aluminum door profile of - AA6060

1) Material : 6063 6061 6060 and different aluminium alloy

2) Alloy Temper: T4 T5 T6 or other special status as per customer's needing.

3) Optional Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrophoretic sliver, electrophoretic champagne, electrophoretic golden,

electrophoretic titanium, machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4) Annual capacity : 120000TON

5) Quality : China Nation Standard GB/T 5237 2004 (advanced class)

6) Application: can be widely used for aluminium window, door, curtain wall, hand railing ,

normal aluminium profiles, decoration and industrial aluminium profiles.

7) Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Are aluminum profiles suitable for outdoor furniture and fences?

- <p>Yes, aluminum profiles are commonly used for outdoor furniture and fences due to their durability, resistance to corrosion, and low maintenance requirements. Aluminum doesn't rust like iron or steel, making it ideal for outdoor applications where exposure to weather elements is constant. It also retains its structural integrity over time and can be easily powder-coated or anodized for added protection and aesthetic appeal.</p>

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: Are aluminum profiles suitable for mass production or large-scale projects?

- Yes, aluminum profiles are highly suitable for mass production or large-scale projects. Aluminum is a lightweight and durable material that offers numerous advantages for industrial use. Its strength-to-weight ratio is excellent, allowing for the creation of lightweight but robust structures. This makes it easier to transport and assemble large-scale projects while maintaining structural integrity. Aluminum profiles can be easily extruded into various shapes and sizes, providing flexibility in design and accommodating different project requirements. The extrusion process is highly efficient, making it cost-effective for mass production. Additionally, aluminum is a highly recyclable material, making it environmentally friendly and sustainable for large-scale projects. Moreover, aluminum profiles offer excellent corrosion resistance, which is crucial for projects in outdoor or harsh environments. They can withstand extreme temperatures, UV radiation, and moisture, ensuring long-term durability and reducing maintenance costs. The versatility of aluminum profiles also allows for easy integration with other materials, such as glass or composite panels, enhancing the aesthetic appeal and functionality of the final product. Overall, the versatility, strength, lightweight nature, cost-effectiveness, and environmental sustainability of aluminum profiles make them an ideal choice for mass production or large-scale projects.

- Q: Can aluminum profiles be used for stadium seating?

- Certainly! Stadium seating can indeed use aluminum profiles. Modern stadium construction often opts for aluminum profiles due to the various advantages they offer. To begin with, aluminum profiles possess a lightweight characteristic, making them easy to install and transport. Consequently, construction times are accelerated, and the overall weight burden on the stadium structure is reduced. Moreover, aluminum profiles exhibit exceptional durability and resistance to corrosion, rendering them ideal for outdoor applications. This is particularly important as stadium seating is exposed to diverse weather conditions. As a result, the seating remains in excellent condition for extended periods, minimizing the necessity for frequent repairs or replacements. Furthermore, aluminum profiles can be effortlessly customized and fabricated into numerous shapes and sizes to meet the precise design requirements of the stadium. This adaptability enables the creation of unique seating arrangements and configurations, thereby optimizing the spectator experience. Additionally, aluminum profiles showcase an outstanding strength-to-weight ratio, offering structural stability and support for the seating. This ensures the safety and comfort of spectators during events. In conclusion, aluminum profiles represent a versatile and pragmatic choice for stadium seating due to their lightweight nature, durability, customization options, and strength. These profiles provide numerous benefits that contribute to the overall success and functionality of a stadium seating system.

- Q: Can aluminum profiles be used in solar mounting systems?

- Yes, aluminum profiles can be used in solar mounting systems. Aluminum is a popular choice for solar mounting systems due to its lightweight, durability, and corrosion resistance properties. It is also easy to fabricate and install, making it an ideal material for constructing solar panel frames, rails, and supports. Additionally, aluminum profiles can be easily recycled, making them an environmentally friendly choice for solar mounting systems. Overall, aluminum profiles are a reliable and efficient option for solar mounting systems.

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- Aluminum profiles and plastic doors and windows are not absolute, which is good or bad, each has its own advantages.1, Aluminum Alloy regular manufacturers are standard models of materials, thickness of 1.2 mm or more, and surface spraying or electrophoresis are very bright, the thickness of the coating is thick, make the effect and its performance are good. The insulation and heat insulation effect of the doors and windows made of plastic steel profiles and plastics are very good. Advantages: heat insulation, heat preservation, sound insulation, aging resistance, tightness2, plastic doors and windows using multi-layer sealing design, and type only smooth surface, not easy to adhesion dust, dirt, dustproof effect is excellent. Elegant and beautiful, plastic steel can be matched into a variety of colors.

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: How do aluminum profiles perform in terms of corrosion resistance?

- The outstanding corrosion resistance of aluminum profiles is well-known, attributed to the formation of a protective oxide layer on the surface. This oxide layer effectively shields against corrosion, even in challenging environments, acting as a barrier to halt further oxidation and corrosion. Moreover, the corrosion resistance of aluminum profiles can be further improved through diverse surface treatments like anodizing or powder coating, offering supplementary defense against corrosion. Consequently, aluminum profiles possess remarkable corrosion resistance, rendering them ideal for a vast array of applications in industries such as construction, transportation, and manufacturing.

- Q: How much is aluminum section ton?

- Aluminum price = aluminum ingot price + processing fee + packing feeAccording to today's Yangtze River aluminum ingot price, 13350+ processing costs 3500-1200 (due to surface processing costs are not the same, floating) + packaging materials costsToday, the South China Sea informed aluminum ingot prices 13990+ processing costs, 3500-1200+ packaging materials costs, so that we can draw aluminum http://www.yzlvcai price. Mainly based on the price of aluminum ingot floating and calculate the price, so it is not a die price.

Send your message to us

Aluminum Windows Profiles - Heat Insulation Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords