Prepainted Aluminum Coil for Sale - 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluminium Coil 1060 3003 3105 Description:

Pre-painted Aluminium Coil 1060 3003 3105 are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Pre-painted Aluminium Coil 1060 3003 3105:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

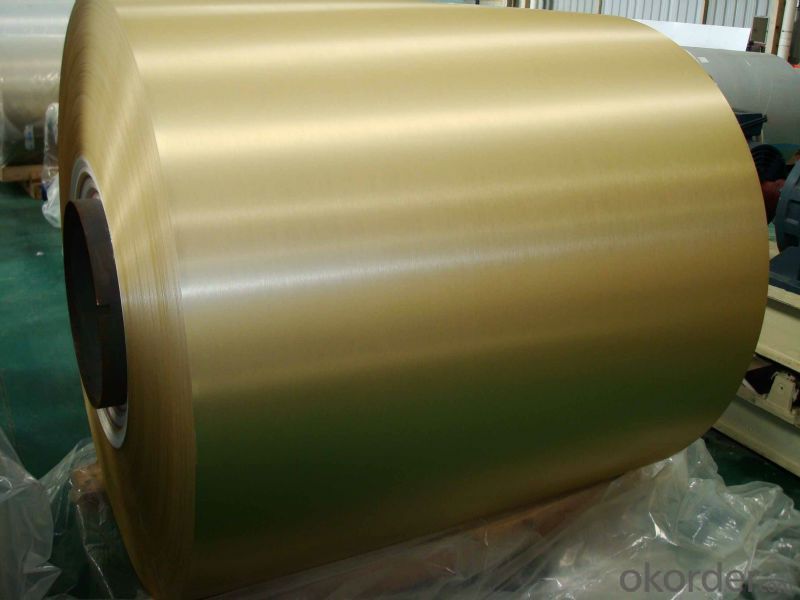

Images of the Pre-painted Aluminium Coil 1060 3003 3105:

Pre-painted Aluminium Coil 1060 3003 3105 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the typical applications of aluminum coils in the automotive industry?

- Due to their advantageous properties, aluminum coils are widely utilized in various applications within the automotive industry. One particular use is in the manufacturing of heat exchangers, like radiators and condensers, which greatly benefit from aluminum's high thermal conductivity. This allows for efficient heat transfer, which in turn enhances the cooling efficiency of both the vehicle's engine and air conditioning system. Another common application of aluminum coils in the automotive sector involves constructing lightweight body panels and structural components. Aluminum's low density is well-known for reducing the overall weight of vehicles, resulting in improved fuel efficiency and reduced emissions. Additionally, the high strength-to-weight ratio of aluminum makes it an ideal material for impact-absorbing structures, thus enhancing vehicle safety. Aluminum coils are also extensively used in the production of electrical wiring systems and connectors in automobiles. Its excellent electrical conductivity enables efficient transmission of electrical signals throughout the vehicle. Furthermore, aluminum's corrosion resistance properties make it suitable for use in various weather conditions. Furthermore, aluminum coils are also employed in the production of suspension systems, including control arms and knuckles. The stiffness and durability of aluminum contribute to enhanced handling and responsiveness, ultimately resulting in improved driving dynamics. In conclusion, aluminum coils find typical applications in the automotive industry, including heat exchangers, lightweight body panels, electrical wiring systems, and suspension components. These applications effectively utilize the advantageous properties of aluminum, such as high thermal conductivity, low density, excellent electrical conductivity, and corrosion resistance.

- Q: What do the two items (COIL:873347 HEAT: number) on the label of the raw material of aluminum coil stand for?

- COIL means aluminum coil and HEAT means heating, so together they mean hot rolled coil.

- Q: Explain how aluminum coils function to shield against electromagnetic interference.

- <p>Aluminum coils protect against electromagnetic interference (EMI) through a process known as electromagnetic shielding. Aluminum, being a conductive material, can reflect and absorb EMI, preventing it from penetrating the protected area. When an aluminum coil is used as a shield, it creates an electric field that interacts with the EMI, either reflecting the interference back or absorbing it, thus reducing its impact on sensitive electronic equipment. The high conductivity of aluminum also allows it to distribute the EMI evenly across its surface, minimizing the effect of any single point of entry. This shielding is crucial in various applications, such as in electronic devices and communication systems, to ensure reliable performance and data integrity.</p>

- Q: Is it advisable to use a hammer to open a stuck aluminum coil?

- <p>Using a hammer to break open an aluminum coil that is stuck closed is not recommended. Aluminum is a soft metal and can be easily damaged by blunt force. Instead, try using pliers or a screwdriver to gently pry open the coil. If the coil is rusted or stuck due to other reasons, applying a penetrating oil or lubricant might help loosen it without causing damage. Always prioritize safety and the preservation of the material when attempting to open or unstick objects.</p>

- Q: How are aluminum coils cleaned before further processing?

- To guarantee the elimination of any contaminants or impurities, aluminum coils undergo a series of steps for cleaning prior to further processing. The cleaning process entails the utilization of chemical solutions and mechanical techniques. Initially, the coils are immersed in a degreaser or cleaning solution to dissolve and eradicate any oils, greases, or dirt present on the surface. This stage is essential in eradicating organic contaminants that may hinder subsequent processes. Following the soaking, the coils typically undergo a high-pressure water rinse to eliminate any remaining residues or particles. This step aids in dislodging and flushing out loosened contaminants from the coil surface. In certain instances, a combination of chemical cleaning and mechanical scrubbing or brushing may be employed to effectively eliminate stubborn or baked-on contaminants. This method is particularly beneficial for coils exposed to harsh environmental conditions or industrial processes. Once the coils have been cleaned, they are typically rinsed again to ensure complete removal of any cleaning agents or residues. This is crucial to prevent any adverse effects or interference with subsequent processing stages. Overall, the cleaning of aluminum coils prior to further processing plays a vital role in achieving high-quality end products. It ensures impurity removal, enhances the surface finish, and improves the overall performance and lifespan of the finished aluminum products.

- Q: Can aluminum coils be used for heat dissipation purposes?

- Yes, aluminum coils can be used for heat dissipation purposes. Aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat away from a source. Aluminum coils are commonly used in various cooling applications such as air conditioning systems, refrigerators, and heat exchangers to dissipate heat effectively and maintain optimal temperatures.

- Q: What is the typical coil width for aluminum coils?

- The typical coil width for aluminum coils can vary depending on the specific application and industry. However, in general, the coil width for aluminum coils can range from a few inches to several feet. Common coil widths for aluminum coils used in construction, automotive, and packaging industries typically range from 12 inches to 72 inches. These coil widths are often selected based on the requirements of the manufacturing process, the final product dimensions, and the equipment used for coil processing. It is important to note that specific coil widths may be customized based on the customer's needs and production capabilities of the aluminum coil manufacturer.

- Q: Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making it suitable for applications where high temperatures are involved.

- Q: Can aluminum coils be used in food processing applications?

- Yes, aluminum coils can be used in food processing applications. Aluminum is a highly versatile and commonly used material in the food industry because of its numerous benefits. Aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for applications that require even and efficient heat transfer. In food processing, aluminum coils are often used in equipment such as heat exchangers, evaporators, and refrigeration units. They are used to cool, heat, or maintain the temperature of various food products during processing, storage, or transportation. The excellent thermal conductivity of aluminum ensures that heat is evenly distributed, helping to preserve the quality and taste of the food. Additionally, aluminum is a non-toxic and non-reactive metal, which means it does not affect the flavor or composition of the food being processed. It also has a natural resistance to corrosion, ensuring that the coils do not contaminate the food and are easy to clean and maintain. Furthermore, aluminum is a sustainable and recyclable material, aligning with the growing demand for environmentally friendly practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation costs. Overall, aluminum coils are a safe, efficient, and reliable choice for food processing applications, meeting the stringent requirements of the industry while maintaining the quality and safety of the processed food.

- Q: Inquiry about the feasibility of using aluminum coils for crafting jewelry or accessories.

- <p>Yes, you can use aluminum coils to make jewelry or accessories. Aluminum is lightweight, durable, and non-allergenic, making it a popular choice for crafting. It's easy to shape and work with, and it's also cost-effective compared to precious metals. You can create rings, bracelets, necklaces, and various other decorative items. Just ensure you use the right tools and safety precautions when working with metal, and finish your creations with appropriate polishing and sealing to enhance their appearance and longevity.</p>

Send your message to us

Prepainted Aluminum Coil for Sale - 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords