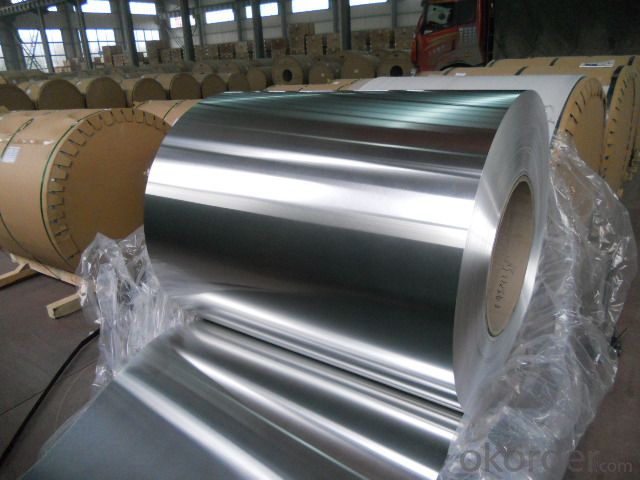

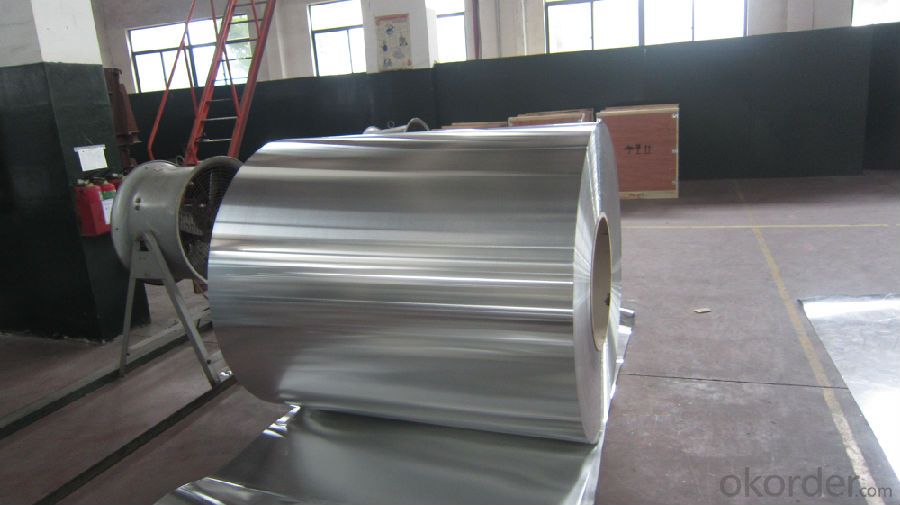

Aluminum Coil Material - 1060, 1100, 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) alloy number 1050 1060 1100 1200 3003 5052 5754 6061 8011.

2) temper available O H12 H14 H16 H18.

3) application: decoration, interior wall

4) thickness: 0.15--2mm

5) width: 2200mm max

6) production treatment: cold rolled or hot rolled.

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | 0.050 | 0.030 | 99.5 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030.- | - | 0.050 | 0.030 | 99.6 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | 0.040 | 0.030 | 99.7 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.0 | |

FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: i need to know if Aluminum absorbs radio waves (just the type that control an RC jet)

- Aluminum is a good conductor of electricity. If an object is completely encased in a conductor (forming a Faraday cage), the object will be shielded from radio waves. If the aluminum (or another conductor) covers only part of the object, radio waves may still reach it.

- Q: Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various industrial applications, including piping systems.

- Q: Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- You are suggested to use eddy current displacement sensor KD2306 to measure aluminum.

- Q: Can aluminum coils be used in architectural applications?

- Yes, aluminum coils can be used in architectural applications. Aluminum is a versatile material that offers excellent durability, corrosion resistance, and a lightweight nature, making it suitable for various architectural uses. It is commonly used in roofing, cladding, facades, windows, and other decorative elements in buildings.

- Q: What is the thermal conductivity of aluminum coils?

- Compared to other metals, aluminum coils exhibit a relatively high thermal conductivity. With approximately 237 W/m·K, aluminum possesses excellent heat conduction capabilities. This particular attribute renders aluminum coils well-suited for situations necessitating efficient heat transfer, like heat exchangers or air conditioning systems. The remarkable thermal conductivity of aluminum enables rapid and effective dissipation of heat, thereby guaranteeing optimal performance and energy efficiency across diverse industrial and residential environments.

- Q: How are aluminum coils used in the production of aircraft components?

- Aluminum coils are used in the production of aircraft components as they can be easily formed, shaped, and joined together to create various parts such as fuselage panels, wings, and structural elements. The coils are typically processed through a series of steps including cutting, bending, and welding to fabricate these components. The lightweight and high strength properties of aluminum make it an ideal choice for aircraft applications, as it helps to reduce the overall weight of the aircraft while maintaining structural integrity.

- Q: How do aluminum coils compare to other types of metal coils?

- Aluminum coils are lighter in weight compared to other types of metal coils, making them easier to handle and install. They also have excellent corrosion resistance, ensuring durability and longevity. Additionally, aluminum coils have good thermal conductivity, allowing for efficient heat transfer. However, they may have lower tensile strength compared to certain other metal coils. Overall, aluminum coils offer several advantages and are commonly used in various industries including HVAC and automotive.

- Q: I HEARD THAT ALUMINUM POWDER TIGHTEN YOUR VAGINA BUT WHERE DO I BUY IT AND HAVE ANY ONE HEARD OF BEYDARY PILLS, I HEARD THEY TIGHTEN YOUR VAGINA ALSO AND WHERE CAN I BUY THEM

- It's not aluminum powder; it's ALUM powder, which is a different chemical. However, it doesn't really tighten your vagina, despite what some ads will say. I have not heard of beydary pills, but I also doubt that they would do anything to fix the problem either. If a real vaginal shrinking pill was available, it would be well-known and very popular, just like viagra is. Your best bet is to do kegel exercises to strengthen and tone your vaginal muscles. These, and nothing else, can help make your vagina tighter.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: Are aluminum coils suitable for heat exchanger fins?

- Yes, aluminum coils are suitable for heat exchanger fins. Aluminum has excellent thermal conductivity, lightweight properties, and corrosion resistance, making it an ideal choice for heat transfer applications. Additionally, aluminum coils can be easily formed into various shapes and sizes, allowing for efficient heat exchange in heat exchangers.

Send your message to us

Aluminum Coil Material - 1060, 1100, 1200 O Aluminum Strip Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords