Aluminum Solar Module Frame AA6061 with T Slot Miter T Track Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

Aluminum alloy6061/6063 T3-T8 or follow customer’s demand.( Aluminium profile for PV solar panel frame)

Surface treatment:

1.Anodizing: silver/black mainly and other multicolor.

2.Electrophoresis

3.Powder coating/ PVDF polishing/ sand blasting etc.

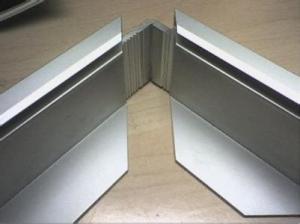

Two types:

1) 90-angle

2) 45-angle

Specifications:

1)30*25mm suitable for 30-120W solar modules.

2)35*35mm suitable for 160-220W solar modules.

3)40*35/45*35/50*35 suitable for 200w above.

The size are available in accordance with customers' requirement.

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Mechanical properties are inconsistent, T5 tensile strength is 160 MPa; T6 tensile strength is 215 mpa. (normally determined by this method) do a tensile test and you'll see

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Here are a few guidelines to follow: 1. Regular cleaning: Aluminum profiles should be regularly cleaned to maintain their appearance and prevent corrosion. Use a mild soap or detergent mixed with water to clean the surface. Avoid using abrasive cleaners or steel wool as they can scratch the aluminum. 2. Avoid harsh chemicals: Harsh chemicals can damage the protective coating on the aluminum profiles. Avoid using strong acids, alkaline cleaners, or solvents for cleaning purposes. 3. Rinse thoroughly: After cleaning, make sure to rinse the aluminum profiles thoroughly with clean water. This will remove any residue from the cleaning solution and prevent streaking. 4. Dry thoroughly: After rinsing, dry the aluminum profiles completely using a soft cloth or towel. Moisture left on the surface can lead to corrosion, so it's important to ensure the profiles are completely dry. 5. Lubrication: If the aluminum profiles have moving parts or hinges, it's recommended to lubricate them regularly to ensure smooth operation. Use a lubricant specifically designed for aluminum to avoid any adverse effects. 6. Protective coatings: Some aluminum profiles come with protective coatings, such as anodized or powder-coated finishes. These coatings provide an extra layer of protection against corrosion and should be maintained as per the manufacturer's instructions. 7. Avoid abrasive cleaning tools: When cleaning aluminum profiles, avoid using abrasive cleaning tools such as brushes or scouring pads. These can scratch the surface and damage the protective coating. It's important to note that specific cleaning and maintenance instructions may vary depending on the type and finish of the aluminum profiles. Therefore, it's always advisable to refer to the manufacturer's guidelines for the best cleaning and maintenance practices for your specific aluminum profiles.

- Q: Are aluminum profiles suitable for cleanroom partitions?

- Yes, aluminum profiles are suitable for cleanroom partitions. They offer a lightweight and durable solution that is resistant to corrosion and easy to clean, making them ideal for maintaining a clean and sterile environment in cleanrooms. Additionally, aluminum profiles can be customized to fit specific requirements, allowing for flexibility in design and construction.

- Q: Are aluminum profiles suitable for cleanroom applications?

- Yes, aluminum profiles are suitable for cleanroom applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for use in cleanroom environments where cleanliness and hygiene are paramount. Aluminum profiles can be easily cleaned and sterilized, and their smooth surface prevents the accumulation of dirt, dust, or particles that can contaminate the cleanroom atmosphere. Additionally, aluminum profiles can be customized and easily integrated with other cleanroom components, such as panels and doors, to create a seamless and hygienic environment. Overall, aluminum profiles offer the required strength, cleanliness, and versatility needed for cleanroom applications.

- Q: How do you join two aluminum profiles together?

- One common method to join two aluminum profiles together is by using aluminum extrusion connectors. These connectors are designed to fit into the profile's T-slot or slot, allowing them to be easily connected and secured using screws or bolts. This method provides a strong and durable connection, ideal for constructing various structures and frames.

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Before inadvertently arrived, as if on the South Fengtai Road, and now do not know where.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors used with aluminum profiles, including corner brackets, corner blocks, T-slot corner connectors, and corner gussets. These connectors help to create strong and stable joints between aluminum profiles, allowing for the construction of various structures and frameworks.

- Q: What are the different packaging and shipping considerations for aluminum profiles?

- When it comes to packaging and shipping aluminum profiles, there are several considerations that need to be taken into account. Firstly, the packaging material used should be strong and sturdy enough to protect the profiles from any external damage during transit. This could include using materials such as corrugated cardboard boxes or wooden crates. Another important consideration is the proper padding and cushioning inside the packaging to prevent any movement or shifting of the profiles. This can be achieved by using protective packaging materials such as foam inserts, bubble wrap, or packing peanuts. These materials help absorb shock and provide a layer of protection against impacts or vibrations that may occur during transportation. Additionally, it is crucial to ensure that the packaging is properly sealed and secured to prevent any accidental opening or damage to the profiles. This can be achieved using strong adhesive tapes or strapping materials to keep the packaging intact. The size and weight of the aluminum profiles should also be taken into consideration when choosing the appropriate packaging. Larger or heavier profiles may require custom-made crates or pallets to facilitate safe and efficient transportation. It is essential to ensure that the packaging is designed to handle the weight and dimensions of the profiles to prevent any structural damage. Furthermore, labeling and marking the packages correctly is crucial to ensure their proper handling and identification during shipping. This includes clearly indicating fragile or delicate items, providing handling instructions, and marking the packages with necessary shipping information like destination address, contact details, and any specific instructions for the carrier. Lastly, it is vital to choose a reliable and experienced shipping carrier or logistics provider who specializes in handling aluminum profiles. They should have the necessary expertise and equipment to handle and transport these delicate products safely and efficiently. Overall, considering the appropriate packaging materials, cushioning, sealing, labeling, and choosing a reliable shipping partner are crucial considerations when packaging and shipping aluminum profiles to ensure their safe delivery to the intended destination.

Send your message to us

Aluminum Solar Module Frame AA6061 with T Slot Miter T Track Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords