Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

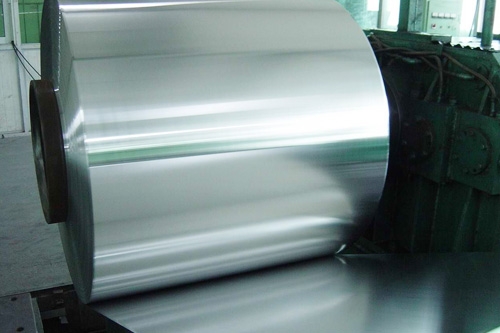

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet ,The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.we have a good reputationin the field of aluminium material, besides, we are one global 500 enterprise, so you can really feel free for our production quality, if you are interested in any of our products, feel free to show us your detailed inquiries later, we give you best price, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1100mm*2200mm,1200mm*2400mm,1220mm*2440mm,1500mm*6000mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the width range?

---It is from 1000mm to 2500mm, etc.

where is your client from?

----normally they are from UAE, ARAB, SINGAPORE, INDONESIA, ETC.

How many tons did they order in one year?

---normally it is around 9000 tons totally.

what is your MOQ now?

---normally it is around 5 tons/eah size.

how often did client place one order yet?

---it is around 1 month, etc.

what is your mainly products?

---Normally they are aluminum sheet, aluminum coil, chekcered sheet, mirror finish sheet, etc.

On the material terms: the cost price of aluminum is five times more than the cost price of iron, it is to count the cost of recycling, a price of aluminum is a hair, a tin price is 2 points, chose the high cost of embossing aluminum evaporator because the aluminum evaporative cooling effect is best, ordinary refrigerator uses wire tube evaporator in order to save costs, cut corners!

Embossed aluminum embossed aluminum plate and can be referred to as: aluminum plate on the basis of belonging through the rolling process in a variety of patterns formed on the surface of aluminum products, is widely used, and mainly used in packaging, construction, walls, and so on.

Aluminum refers to aluminum or aluminum alloy material processed into (cut or sawn) obtained by pressure rectangular cross section, material thickness uniform rectangular international customary to more than 0.2mm thickness, 500mm or less, 200mm width above, aluminum length 16m or less called aluminum sheet aluminum sheet, 0.2mm or less as aluminum foil, a width of less than 200mm row material or strip (of course with the progress of large equipment, the widest 600mm can be achieved exclusive material will be more).

- Q: This question seeks to understand the specific characteristics of aluminum sheets that make them suitable for various applications.

- <p>Aluminum sheets possess several properties that make them versatile for different applications: 1. Corrosion resistance: Aluminum forms a protective oxide layer, which makes it resistant to corrosion. 2. Lightweight: Aluminum is lighter than many other metals, which is beneficial for applications where weight is a concern. 3. High strength-to-weight ratio: Despite being lightweight, aluminum is strong and durable. 4. Good thermal and electrical conductivity: Aluminum conducts heat and electricity well, making it ideal for heat sinks and electrical components. 5. Formability: Aluminum can be easily shaped and bent, which is useful in construction and manufacturing. 6. Recyclability: Aluminum is highly recyclable, reducing waste and environmental impact. 7. Reflectivity: Aluminum reflects light and heat, which is useful in applications like solar reflectors and insulation. These properties vary in importance depending on the specific application, such as construction, automotive, aerospace, or consumer goods.</p>

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: What are the different forming methods for aluminum sheets?

- The different forming methods for aluminum sheets include rolling, stamping, deep drawing, bending, and stretch forming. Rolling involves passing the aluminum sheet through a series of rollers to reduce its thickness and increase its length. Stamping uses a die to shape the sheet by applying pressure. Deep drawing involves pulling the sheet into a die cavity to create a deep and complex shape. Bending is used to create curves and angles in the sheet by applying force. Stretch forming stretches the sheet over a die to create a contoured shape.

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent. Aluminum is known for its excellent malleability and ductility, which allows it to be easily formed into various shapes and bends. It can be manipulated using a variety of techniques such as rolling, pressing, or even using hand tools. The malleability of aluminum makes it a preferred choice in industries such as automotive, aerospace, and construction, where it is commonly used in the production of parts and structures that require complex shapes and bends. Additionally, aluminum's lightweight and corrosion-resistant properties further contribute to its suitability for shaping and bending processes.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- I helped a friend restore an old Honda 160. We did a combination of the things mentioned. We painted the engine cases with a high temp aluminum paint. We did the side covers by wet sanding with 400-800-1000 and then finishing with Semichrome. Other misc bits we went with flat black (makes the polished aluminum pop). It wasn't exactly stock, but it looked great. It would take an expert to know the difference.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is an excellent conductor of heat, and its high thermal conductivity makes it an ideal material for dissipating heat generated by LED lights. The use of aluminum sheets as heat sinks helps to transfer the heat away from the LED chips, preventing overheating and prolonging the lifespan of the LED lighting system. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular choice for heat sink applications in LED lighting.

- Q: Are aluminum sheets suitable for aerospace applications?

- Indeed, aluminum sheets prove to be an excellent choice for aerospace applications. The aerospace industry widely utilizes aluminum due to its remarkable blend of strength, lightweight characteristics, and resistance to corrosion. Its exceptional strength-to-weight ratio renders it an ideal selection for the fabrication of various aircraft structures, such as fuselages, wings, and crucial components. Moreover, aluminum sheets possess the advantageous ability to be easily formed into intricate shapes, thereby facilitating the manufacturing process. Furthermore, aluminum boasts commendable thermal conductivity, which proves advantageous for dissipating heat in the realm of aerospace applications. In summary, aluminum sheets successfully fulfill the stringent requirements of the aerospace industry and are extensively employed in the construction of contemporary aircraft.

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

Send your message to us

Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords