Aluminum Sheets Winnipeg - Marine Grade 5 Series Aluminium Flat Plate Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Flat Plate 5 Series Alloy for Marine Boat

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Aluminium Flat Plate 5 Series Alloy for Marine Boat

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Aluminium Flat Plate 5 Series Alloy for Marine Boat

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

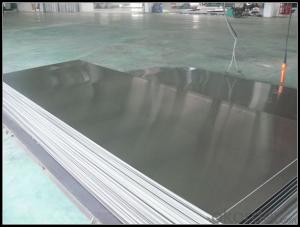

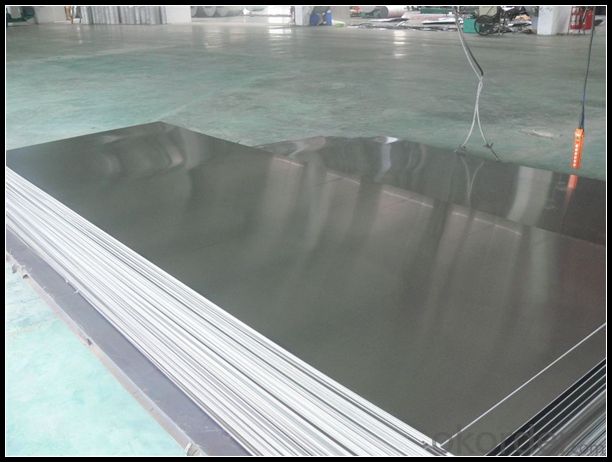

5. Image of Aluminium Flat Plate 5 Series Alloy for Marine Boat

6. Package and shipping of Aluminium Flat Plate 5 Series Alloy for Marine Boat

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- Nichols was eventually recognized as the inventor of transparent aluminum.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several different types of finishes available for painted aluminum sheets, each offering unique characteristics and benefits. 1. Matte Finish: This finish provides a non-reflective, dull appearance to the painted aluminum sheet. It is commonly used in applications where a low-gloss finish is desired, such as architectural elements or interior design. 2. Gloss Finish: A gloss finish gives the painted aluminum sheet a shiny, reflective surface. It is often chosen for applications where a sleek and polished appearance is desired, such as automotive parts or decorative panels. 3. Textured Finish: A textured finish adds a raised pattern or texture to the surface of the painted aluminum sheet. This type of finish is commonly used for decorative purposes, as it can enhance the visual appeal and provide a unique tactile experience. 4. Metallic Finish: A metallic finish gives the painted aluminum sheet a metallic appearance, resembling the look of metal alloys like stainless steel or bronze. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder Coating Finish: Powder coating is a popular finishing method that involves applying a dry powder to the surface of the painted aluminum sheet and then curing it under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Clear Coat Finish: A clear coat finish is often applied over a painted aluminum sheet to provide an extra layer of protection and enhance its durability. This finish is typically transparent and helps to resist damage from UV rays, moisture, and other environmental factors. It is important to consider the intended use and desired aesthetic when choosing a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

- Q: Are aluminum sheets suitable for automotive heat shields?

- Yes, aluminum sheets are suitable for automotive heat shields. They have excellent thermal conductivity and high melting point, making them effective in dissipating heat and protecting sensitive components from excessive temperature. Additionally, aluminum is lightweight and corrosion-resistant, which are desirable qualities for automotive applications.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- Home Depot sells quality aluminium receptacles. Not doubting your father totally but an electrician needs to check the inside of the panel. A number of things can go and the breaker wont be effected. If the problem is not within the panel an electrician can trace the dead circuits and isolate the problems. Hopefully your new but old home does not have any concealed electrical boxes. Sometimes in older homes the previous owner may have added some electrical items and any Joe could have did it. Believe me I've seen a lot in my 15 years of practice.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Aluminum sheets are indeed a fitting choice for HVAC systems. The popularity of aluminum in HVAC systems stems from its numerous advantageous properties. To begin, aluminum is both lightweight and robust, making it effortless to handle and install in HVAC systems. Its low density also enables cost-effective transportation and reduces the overall weight of the HVAC units. Furthermore, aluminum possesses exceptional resistance to corrosion. Given that HVAC systems often encounter moisture and condensation, particularly in air conditioning units, aluminum's corrosion resistance ensures its durability and longevity in such environments. Moreover, aluminum sheets exhibit commendable thermal conductivity, facilitating efficient heat transfer throughout the HVAC system. This property holds particular significance in heating and cooling applications, as it aids in effectively distributing the desired temperature. In addition, aluminum is a non-toxic material, rendering it safe for use in HVAC systems that circulate air within buildings. It does not emit any harmful particles or gases, thereby ensuring the quality of indoor air. Lastly, aluminum is highly recyclable, contributing to its environmental friendliness. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability objectives. Taking all these advantages into account, aluminum sheets undeniably prove suitable for use in HVAC systems. They offer an optimal combination of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

Send your message to us

Aluminum Sheets Winnipeg - Marine Grade 5 Series Aluminium Flat Plate Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords