Aluminum Sheets Products Manufacturers 3XXXX

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

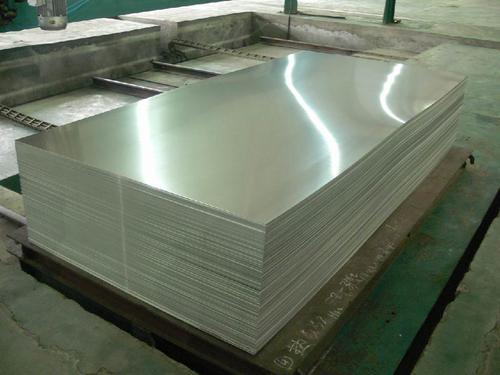

1.Structure ofAluminum Sheets D.C 3XXX Description

Aluminum Sheets D.C 3XXX is cut from aluminum coils 3xxx. Aluminum Sheets D.C 3XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets D.C 3XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets D.C 3XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

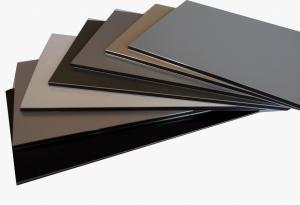

3.Aluminum Sheets D.C 3XXX Images

4.Aluminum Sheets D.C 3XXX Specification

| Alloy | AA3xxx (AA3003,AA3004,AA3005,AA3105 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets D.C 3XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets D.C 3XXX products.

B.When will you deliver the products?

The Aluminum Sheets D.C 3XXXwill be delivered within 35 days after receiving advanced payment or original L/C.

Many do not understand the building renovation layman should rarely come into contact with "perforated aluminum", and did not know what this aluminum is used for. We will see this application of aluminum is relatively broad, decorative effect is very good. Then, why "perforated aluminum" perforated? This is an issue that many people will answer that in times of stress can be more uniform, to a certain extent, is to strengthen the aluminum load-bearing capacity, the use of aluminum structure more solid, so this kinds of perforated aluminum range of applications is very broad, and the prospects are very bright.

The so-called "perforated aluminum" is the uniform distribution of the same size, the same thickness of the aluminum plate hole, usually made of aluminum or aluminum alloy, the thickness of the aluminum plate is a certain customary provisions, such as the thickness of the aluminum foil, internationally widely recognized that the thickness of 0.2 mm, width of 200 mm or more and a length of 16 meters below called aluminum foil. For many routine perforated aluminum expertise, we need to continue to deepen the understanding of the application of perforated aluminum, so that we can handier in architectural decoration.

For perforated aluminum mounting, we need to consider many factors, such as environmental requirements for aluminum sheet; this requirement is not only reflected in the size requirements, but also in the stability of the aluminum requirements. Therefore, the choice of a suitable size perforated aluminum sheet; we need to note is that the aluminum plate is installed. Do not underestimate the aluminum plate is installed, because the installation method, once is not correct, it will lead to very serious consequences, such as aluminum Wall fell. When installing perforated aluminum, not only in the degree of vertical aluminum very strict requirements on the aluminum plate connection requirements also must not be lost.

So, how can we effectively grasp the perforated aluminum mounting? We have to make the necessary preparations before construction before installing aluminum, such as installation materials, installation tools, and for a certain environment, we must seriously implement good perforated aluminum mounting method, under what circumstances should use what method of installation, which is the focus that we should grasp. Construction process, we must also pay attention to a lot of problems. In perforated aluminum ceiling installation, for example, we should always ensure camber ceiling keel, it is necessary to have a solid formation, which requires the full use of the boom.

Perforated aluminum sheet in our daily lives is not uncommon, but very few people would know that is perforated aluminum. Today many public places to use perforated aluminum curtain wall it will not only beautiful, but also in the firm are also very good.

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Certainly, HVAC systems can utilize 101 aluminum sheets. Due to its exceptional thermal conductivity, resistance to corrosion, and lightweight attributes, aluminum is frequently employed in HVAC systems. The 101 aluminum alloy, a widely utilized grade, offers commendable strength and ductility, rendering it suitable for HVAC applications. It is commonly employed in the manufacturing of ducts, air handlers, heat exchangers, and various other components within HVAC systems. Moreover, aluminum sheets are highly malleable, allowing them to be easily molded and shaped in accordance with the specific demands of the HVAC system.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a durable and lightweight material that is resistant to corrosion and easy to clean, making it a popular choice for food preparation. However, it is important to note that aluminum can react with certain acidic or salty foods, so it is recommended to use a protective barrier such as parchment paper or silicone mats when working with such ingredients.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: I have to find the type of bond that Aluminum (foil) would have. I know that it has some kind of bond to it because that's the kind of question that I got wrong on my last quiz.

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

- Q: Can aluminum sheets be used for missile components?

- Yes, aluminum sheets can be used for missile components. Aluminum is a versatile and lightweight material that possesses excellent strength-to-weight ratio properties. These characteristics make it a suitable choice for various aerospace applications, including missile components. Aluminum sheets offer advantages such as corrosion resistance, high thermal conductivity, and ease of fabrication. Additionally, aluminum can withstand extreme temperatures, making it suitable for use in missile components that may experience high heat during flight. However, it is important to consider the specific requirements of the missile system and consult with experts in the field to ensure that aluminum sheets are suitable for the intended application.

- Q: What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets have excellent electrical conductivity properties due to their high thermal and electrical conductivity. They are widely used in various electrical applications, such as wiring, power transmission lines, and electrical enclosures.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

Send your message to us

Aluminum Sheets Products Manufacturers 3XXXX

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords