Aluminum Sheets Price Philippines - Finished Aluminium Panel for Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

| Finished Aluminium Panel Used For Wall Decoration | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 25MT. | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-60 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

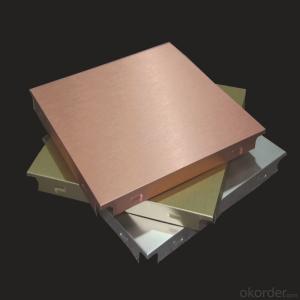

PVDF and PE coated aluminium coils/sheets:

PVDF color pre coated aluminum coils/ sheets:

It is well known that fluorocarbon lacquer coating (PVDF coating) owes the best acid resistant/alkali and temperature tolerant capabilities of all painting materials. Being the best quality of precoated aluminum, PVDF coated coils are especially suitable for outdoor roofing walls and ceiling manufacturing.

Polyester (PE) color pre coated aluminum coils/ sheets :

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage.

Production facilities and processing range

Equipments | Quantity | Thickness range | Width range | Length range | Max loading weight |

Continuous casting rolling mill | 23 | 6.0-10.0mm | 1000-2000mm | ------------- | 15000kgs |

Cold rolling mill | 2 | 0.1-6.0mm | 900-1700mm | ------------- | 12000kgs |

High accuracy cold rolling line | 1 | 0.1-1.0mm | 650-1420mm | ------------- | OD 2000mm |

Annealer | 14x40T | ------------- | -------------- | ------------- | ------------- |

Coating line | 3 | 0.15-1.5mm | 600-1600mm | ------------- | 5000kgs |

Embossing line | 1 | 0.2-1.2mm | 350-1300mm | ------------- | 8500kgs |

Straightening line | 1 | 0.1-2.0mm | 600-1700mm | ------------- | 10000kgs |

Slitting line | 1 | 0.2-3.0mm | 21-1595mm | ------------- | 10000kgs |

Wave shearing line | 1 | 0.13-0.5mm | 550-1230mm | ------------- | 10000kgs |

Shearing line | 3 | 0.125-4.0mm | Max 1700mm | ------------- | 10000kgs |

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: What are the different types of surface treatments available for anodized aluminum sheets?

- There are several types of surface treatments available for anodized aluminum sheets, including polishing, brushing, sandblasting, etching, and coloring. Each treatment option provides a unique aesthetic and functional finish to the aluminum surface.

- Q: What are the advantages of using aluminum sheet in construction?

- Using aluminum sheet in construction offers several benefits. Firstly, its lightweight composition makes it easy to handle and transport on construction sites, reducing the need for heavy machinery and improving efficiency, ultimately leading to cost savings. Secondly, aluminum exhibits exceptional resistance to corrosion, unlike other metals such as steel, making it a durable and suitable material for outdoor applications like roofing or cladding. Additionally, aluminum's versatility allows for easy shaping and forming into various sizes and profiles, providing architects and engineers with greater design flexibility to create innovative and unique structures. Moreover, aluminum is a sustainable choice as it is 100% recyclable, helping reduce waste and minimize the carbon footprint. Furthermore, it possesses excellent thermal and electrical conductivity properties, reflecting heat and light to maintain comfortable indoor temperatures and reduce energy consumption. It also serves as an excellent conductor of electricity, making it ideal for electrical wiring and building components. Lastly, though aluminum may have a higher initial cost, its low maintenance requirements and long lifespan make it cost-effective in the long run. Structures made with aluminum sheet do not require regular painting or upkeep, saving both time and money. In conclusion, the advantages of utilizing aluminum sheet in construction encompass its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness, making it highly desirable for a wide array of construction applications.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- plastic is more harmful when heated, they release dexoxin which is cancer causing. If you use them in micro ovens, its harmfull. Aluminum is much safer to cook in. It can with stand high temperatures.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Indeed, specific sizes can be achieved through the customization of aluminum sheets. Possessing great versatility, aluminum proves itself as a material that can be effortlessly shaped and cut to meet particular needs. By utilizing appropriate tools and equipment, one can achieve precise cuts on aluminum sheets, regardless of their purpose in industrial, commercial, or personal settings. This adaptability allows for the tailoring of aluminum sheets to suit specific applications, rendering it a favored option across various industries such as construction, automotive, and aerospace. Whether one requires compact or expansive aluminum sheets, they can be conveniently tailored to the precise dimensions necessary, guaranteeing an accurate fit for any given project or application.

- Q: What is the thermal conductivity of aluminum sheets?

- Aluminum sheets exhibit high thermal conductivity, reaching around 237 W/m·K. This quality endows aluminum with exceptional heat conduction capabilities, enabling efficient heat transfer between different regions. Consequently, aluminum sheets find widespread application in various domains, including heat sinks, radiators, and cooking pans.

- Q: What are the colors of iron sheet and aluminum sheet?

- silver white

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- Best Epoxy For Aluminum

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

Send your message to us

Aluminum Sheets Price Philippines - Finished Aluminium Panel for Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords