1100 8006 Aluminum Coil - Aluminum Sheets/Coils AA3003 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

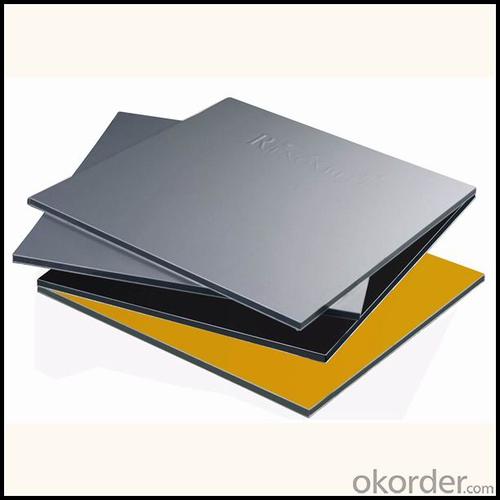

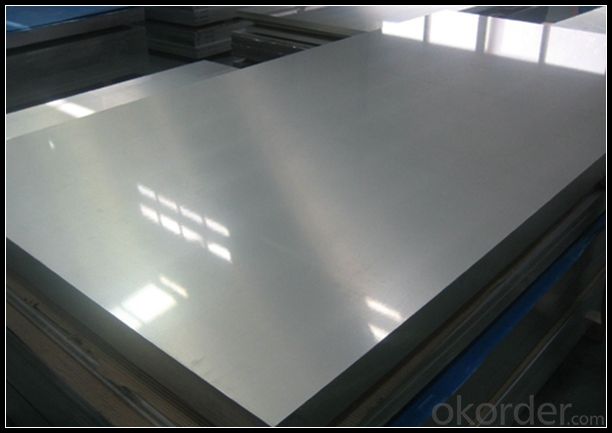

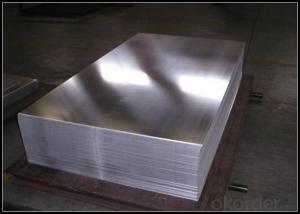

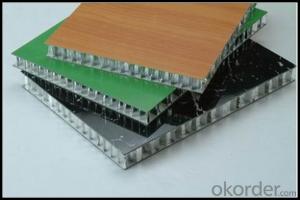

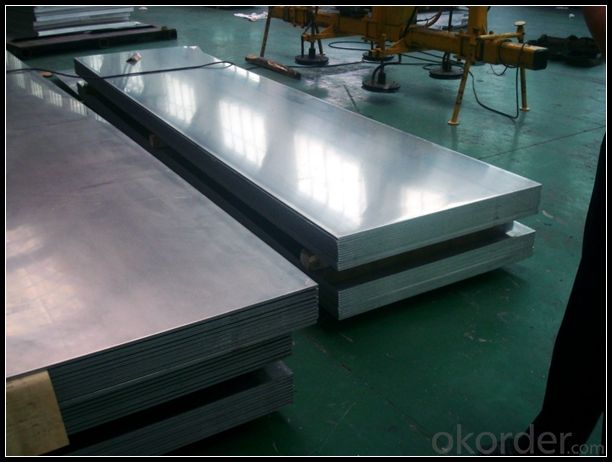

5. Image of Aluminum sheets

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How long do aluminum coils typically last?

- The typical lifespan of aluminum coils is approximately 15 to 20 years, but their longevity is heavily influenced by various factors including the quality of the aluminum, the installation process, and the maintenance and care given to them. The lifespan of the coils can be significantly prolonged by regularly maintaining them, such as by cleaning the coils and ensuring adequate airflow. Moreover, their durability can also be affected by environmental factors like exposure to severe weather conditions and corrosive substances. Hence, ensuring proper care and maintenance is crucial to guarantee the extended lifespan of aluminum coils.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a lightweight, versatile, and corrosion-resistant material that can be easily slit into narrow strips without compromising its structural integrity. Aluminum coils are commonly used in various industries such as automotive, construction, and packaging, where precise and narrow strips are required for specific applications. Additionally, aluminum coils offer excellent formability and surface quality, making them suitable for coil slitting processes that require high precision and consistency.

- Q: I bought some drain opener as a source of sodium hydroxide and it has little silvery balls in it which I believe are aluminium. How can I separate the two substances with minimal loss of the sodium hydroxide? I don't care about the aluminium.

- Trust me. Its not worth salvaging the hydroxide. Aluminum hydroxide is unbelievably stable and that means you probably won't be able to salvage the hydroxide without doing electrolysis or something difficult like that. That's like trying to obtain hydroxide from methanol CH3OH. Oh yea you can make methanol quite easily from a halomethane by reacting it with a hydroxide of some kind. But you will not be able to remove that hydroxide at all without neutralizing it with an acid. Hydroxides are bloody awful leaving groups. That oxygen is really glued on to that carbon well. You have to really destabilize that methanol to remove that hydroxide. Same with the aluminum hydroxide. Very stable and strong bond.

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils have excellent strength-to-weight ratio compared to many other metals. While aluminum is not as strong as steel, it is lighter and more flexible, making it a popular choice in various applications. Aluminum coils can withstand significant forces without breaking or deforming, making them suitable for a wide range of industries, including automotive, aerospace, and construction. Additionally, aluminum coils have good corrosion resistance, which further enhances their durability and longevity. However, it is important to note that the strength of aluminum can vary depending on the alloy and temper used, so specific comparisons should be made based on the particular application and requirements.

- Q: Explain the key differences between aluminum coil and steel coil, including material properties and applications.

- <p>Aluminum coil and steel coil are distinct based on their material composition and properties. Aluminum coil is made from aluminum, a lightweight metal known for its corrosion resistance, high thermal and electrical conductivity, and formability. It is commonly used in applications such as packaging, construction, and electrical components. Steel coil, on the other hand, is made from steel, a stronger and more durable metal that offers greater tensile strength and is more resistant to deformation. Steel is widely used in construction, automotive, and manufacturing due to its strength and durability. The choice between aluminum and steel coil depends on the specific requirements of the application, such as weight, strength, and cost considerations.</p>

- Q: Are aluminum coils available in custom sizes?

- Yes, aluminum coils are available in custom sizes.

- Q: What are the rules and regulations concerning the disposal of old aluminum coils?

- <p>Yes, there are regulations on the disposal of old aluminum coils. These regulations vary by country and region, but generally, they aim to prevent environmental pollution and promote recycling. In the United States, for example, the Environmental Protection Agency (EPA) sets guidelines for recycling and disposing of scrap metal, including aluminum. Businesses and individuals are often required to recycle aluminum coils rather than sending them to landfills. Proper disposal may involve sorting, cleaning, and sending the coils to recycling facilities that can process and reuse the material. Violations of these regulations can result in fines and penalties. It's important to check local and national regulations for specific requirements.</p>

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: Are aluminum coils suitable for construction applications?

- Indeed, construction applications can make good use of aluminum coils. Aluminum, a material known for its lightweight and durability, is extensively utilized in the construction sector. Aluminum coils find frequent application in roofing, siding, gutters, and other exterior uses owing to their resistance against corrosion and ability to withstand inclement weather conditions. Furthermore, their simple installation and maintenance procedures make them highly favored by contractors. Moreover, aluminum coils can be painted or coated to enhance their visual appeal and blend with the overall architectural design of a structure. Ultimately, aluminum coils offer a dependable and economical option for construction purposes.

- Q: Are aluminum coils suitable for electrical grounding applications?

- Yes, aluminum coils are suitable for electrical grounding applications. Aluminum is a highly conductive material, with approximately 61% of the conductivity of copper. It is commonly used in electrical applications where conductivity and corrosion resistance are important factors. Aluminum coils provide a cost-effective alternative to copper coils for grounding purposes. Additionally, aluminum coils are lightweight and easy to work with, making them a popular choice for electrical grounding applications. However, it is important to ensure proper installation and maintenance to prevent any potential issues like galvanic corrosion when connecting aluminum to other metals.

Send your message to us

1100 8006 Aluminum Coil - Aluminum Sheets/Coils AA3003 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords