Red Aluminum Coil Stock AA1050 H14 - Color Coated Aluminum Coil from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

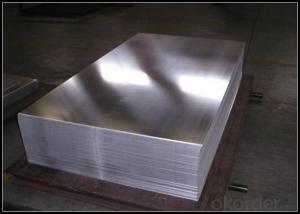

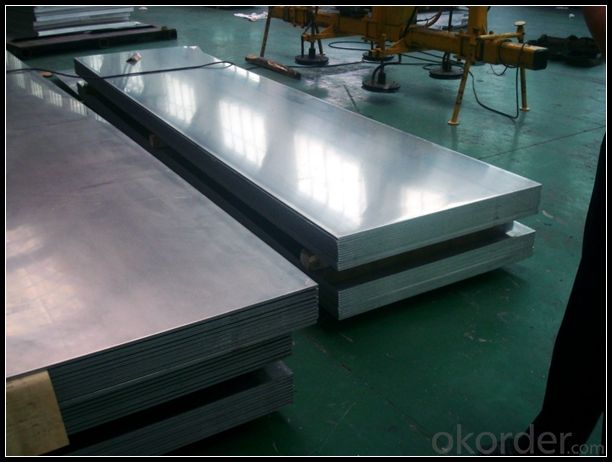

5. Image of Aluminum sheets

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used for marine applications?

- Yes, aluminum coils can be used for marine applications. Aluminum has excellent corrosion resistance properties, making it suitable for marine environments. It is lightweight, durable, and can withstand exposure to saltwater, making it a popular choice for boats, ships, and other marine structures.

- Q: How do aluminum coils contribute to sustainable energy systems?

- Aluminum coils play a crucial role in sustainable energy systems due to several reasons. Firstly, aluminum is a lightweight and highly conductive metal, making it an ideal material for the production of coils used in various renewable energy technologies such as wind turbines, solar panels, and electric vehicles. The lightweight nature of aluminum reduces the overall weight of these systems, thus increasing their efficiency and performance. Secondly, aluminum is abundant in nature and has a high recycling rate. It can be recycled repeatedly without losing its original properties, resulting in significant energy savings and reduced environmental impact. By using aluminum coils, sustainable energy systems can minimize their reliance on virgin materials and promote a circular economy. Furthermore, aluminum coils are corrosion-resistant and have excellent heat transfer properties. This makes them highly durable and capable of withstanding harsh weather conditions, ensuring the longevity and reliability of renewable energy systems. The durability of aluminum coils also reduces the need for frequent maintenance or replacements, thereby minimizing waste generation and conserving resources. Moreover, aluminum is a non-toxic material that poses minimal risks to human health and the environment. Unlike other metals, aluminum does not leach harmful substances into the soil or water, making it a safe choice for sustainable energy systems. Lastly, the use of aluminum coils in sustainable energy systems helps to reduce greenhouse gas emissions. As aluminum is lightweight, it requires less energy to transport and install, thereby reducing the carbon footprint associated with the manufacturing and installation processes. Additionally, the increased efficiency and performance of renewable energy systems using aluminum coils contribute to the displacement of fossil fuel-based energy generation, leading to a reduction in overall carbon emissions. In conclusion, aluminum coils contribute to sustainable energy systems by enhancing the efficiency, durability, recyclability, and environmental friendliness of renewable energy technologies. Their lightweight nature, corrosion resistance, and excellent heat transfer properties make them ideal for various applications, while their abundance and recyclability promote resource conservation and a circular economy. By using aluminum coils, sustainable energy systems can reduce their environmental impact, improve performance, and contribute to a cleaner and more sustainable future.

- Q: Is it possible to utilize aluminum coils in the process of water treatment?

- <p>Yes, aluminum coils can be used for water treatment. They are often used in processes such as coagulation and flocculation, where aluminum salts are added to the water to help remove suspended particles and impurities. The aluminum ions react with the particles in the water to form larger, heavier particles that can be more easily settled or filtered out. Additionally, aluminum coils can be part of an electrode system in electrocoagulation processes, where an electric current is used to treat water by generating aluminum ions at the anode. This method is effective for removing various contaminants, including heavy metals, bacteria, and organic compounds.</p>

- Q: How do aluminum coils perform in cryogenic environments?

- Aluminum coils perform well in cryogenic environments due to their low thermal expansion coefficient and high thermal conductivity. These properties allow the coils to withstand extreme cold temperatures without warping or losing efficiency. Additionally, aluminum's corrosion resistance ensures the longevity and reliability of the coils in such environments.

- Q: What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues in aluminum coils include scratches, dents, stains, oxidation, and uneven coatings.

- Q: How do aluminum coils compare to steel coils in terms of strength?

- Aluminum coils and steel coils differ significantly in terms of strength. Steel coils are generally stronger and more durable than aluminum coils. Steel is known for its high tensile strength and ability to withstand heavy loads, making it a preferred choice for applications that require high strength and durability. On the other hand, aluminum coils have a lower strength compared to steel. Aluminum is a lightweight metal with a lower tensile strength, which means it may not be as resistant to heavy loads or stress as steel coils. However, aluminum coils have other favorable properties such as excellent corrosion resistance and high thermal conductivity. The choice between aluminum and steel coils depends on the specific application and requirements. If strength and durability are the primary concerns, steel coils are usually the better option. However, if weight reduction, corrosion resistance, or thermal conductivity are more important, aluminum coils might be the preferred choice.

- Q: what is the hardness number of aluminium.....? what is the hardness number of aluminium-Sic composite material...?

- I don't believe that Aluminum (US spelling)/ Aluminium (UK spelling) has a Mohs Hardness rating. The Hardness of a material, as measured by the Mohs Hardness scale, is a criterion of its resistance to crushing. [Perry's Chemical Engineering Handbook]. Since aluminum is a metal, and would deform under a crushing-type stress, rather than shatter, it would not have a Mohs Hardness rating. Perhaps you meant **aluminA**, rather than aluminum. Alumina (Al2O3) has a Modified Mohs Hardness of 12. Silicon Carbide (carborundum) has a Modified Mohs Hardness of 13. There's no value listed for the combination, but it should be pretty hard stuff -- likely in the 12-13 range, but potentially even harder. Hope that helps.

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

- Q: What type of equipment is used to process aluminum coils?

- The equipment employed for aluminum coil processing varies depending on the specific manufacturing process and requirements. Nevertheless, there are several common types of equipment used in this process: 1. Uncoilers/Decoilers: These machines are utilized to unroll and straighten the aluminum coils, facilitating further processing. 2. Levelers: Leveling machines are employed to flatten the surface of the aluminum coil, ensuring it is even and flat before proceeding with additional processing. 3. Slitters: Slitting machines are used to cut the aluminum coil into narrower strips of desired widths. This equipment finds frequent use in industries such as automotive, construction, and packaging. 4. Shears: Shearing machines are employed to cut the aluminum coil into specific lengths or shapes required for the manufacturing process. 5. Roll Forming Equipment: Roll forming machines shape the aluminum coil into specific profiles or designs. Commonly employed in the construction industry, they are used to manufacture roofing panels, gutters, and siding. 6. Heat Treatment Furnaces: Heat treatment furnaces subject the aluminum coil to specific temperature conditions to enhance its strength, hardness, or other desired properties. 7. Surface Treatment Equipment: Various equipment, including cleaning machines, chemical baths, and coating lines, are used for surface treatment processes such as cleaning, anodizing, or painting the aluminum coil. These processes improve the coil's appearance, corrosion resistance, or other functional properties. 8. Packaging Equipment: Packaging machines are employed to bundle, wrap, or pack the processed aluminum coils for storage, transportation, or further distribution. It is crucial to note that the specific equipment used may vary depending on factors such as size, thickness, alloy, and intended use of the aluminum coils. Manufacturers often utilize customized equipment to meet their specific requirements and ensure efficient processing.

Send your message to us

Red Aluminum Coil Stock AA1050 H14 - Color Coated Aluminum Coil from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords