Aluminum Roofing Coil - Aluminum Sheets AA1050 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

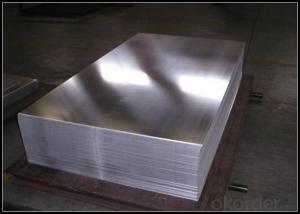

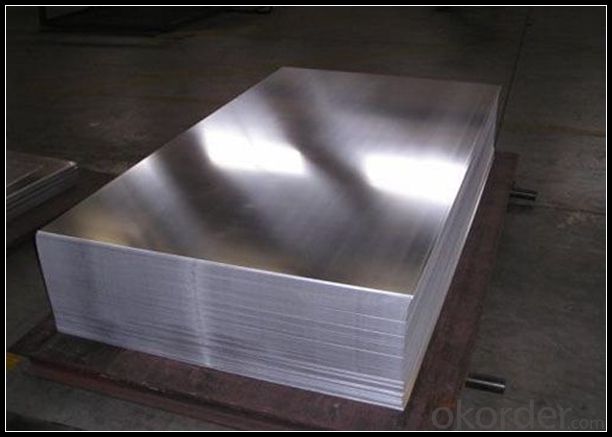

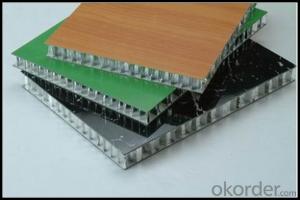

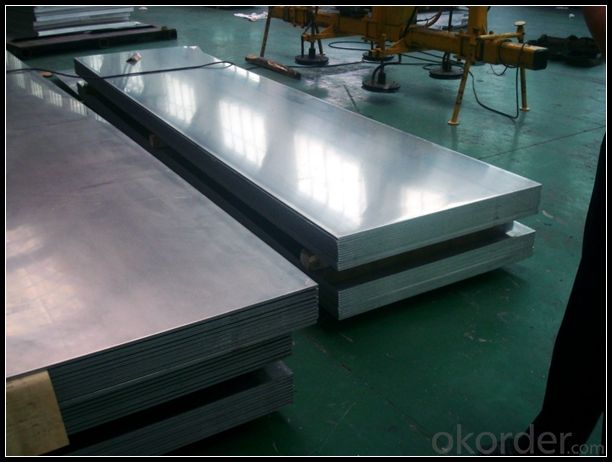

5. Image of Aluminum sheets

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: what language did Aluminum and Uranium originate from ? Who or what were they named for ?

- The ancient Greeks and Romans used alumen (alum, potassium aluminium sulfate, K2Al6(OH)12(SO4)4) in medicine as an astringent, and as a mordant in dyeing. Alum was exported from ancient Greece and Italy. In 1761 the French chemist Louis-Bernard Guyton de Morveau (1737-1816) proposed the name alumine for the base in alum. Guyton de Morveau was instrumental in setting up a standardised system for chemical nomenclature and often collaborated with Antoine Lavoisier, who in 1787, suggested that alumine was the oxide of a previously undiscovered metal. In 1808, Sir Humphry Davy (1778-1829) did experiments for the decomposition of alumine, silex, zircone, and glucine. He failed to isolate the metals in these, as he reported in his paper for the Royal Society of London on 30 June 1808, but he suggested names for the metals (note) Cf. Silicium, Zirconium, and Beryllium (Glucium) Thus he proposed the name alumium for this still undiscovered metal and later agreed to change it to aluminum. Shortly thereafter the name aluminium was adopted to conform with the -ium ending of most elements. Uranium was named by its discoverer German chemist Martin Klaproth, after the last planet to have been discovered Uranus.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during installation and reduces the load on the building's structure. Additionally, aluminum is highly durable and corrosion-resistant, making it a long-lasting option for architectural roofing systems. It also has excellent thermal properties, reflecting heat and reducing energy consumption. Moreover, aluminum coils can be easily shaped and formed into various profiles and designs, allowing for flexibility in architectural styles. Lastly, aluminum is a sustainable material as it is recyclable, making it an environmentally friendly choice for roofing systems. Overall, aluminum coils are a suitable and practical option for architectural roofing systems, providing durability, versatility, and energy efficiency.

- Q: Is it safe or practical to use an electric iron as a heat source for an aluminum coil?

- <p>Using an electric iron to heat an aluminum coil is not advisable. Electric irons are designed to heat their own plates for ironing clothes, not to transfer heat to other materials like aluminum coils. The high temperature of an iron could damage the coil and potentially cause a fire hazard. Moreover, aluminum has a high thermal conductivity, which means it would dissipate heat quickly, making it inefficient to use an iron for this purpose. Always use heating elements specifically designed for the material you intend to heat.</p>

- Q: What influence do aluminum coils have on the welding process?

- <p>Aluminum coils can significantly affect welding work due to their unique properties. Aluminum has a high thermal conductivity, which requires more heat input to achieve the necessary temperature for welding. It also has a high oxide layer that can interfere with the welding process, leading to porosity and poor joint strength if not properly managed. Additionally, aluminum's low melting point can cause challenges in maintaining the correct temperature during welding. Specialized techniques, such as TIG (Tungsten Inert Gas) welding, and the use of appropriate filler materials are often necessary to ensure a successful weld. Proper cleaning and preparation of the aluminum surface are also crucial to prevent contamination and ensure a strong, defect-free weld.</p>

- Q: ok me and my father are trying to make thermite. we have the iron oxide but the aluminum we only have paste and i was wondering would it work the same as if we had the powder.and if it is differnt will it work for the thermite and what will it take to light it.

- Etch A Sketch Thermite

- Q: How does the alloy composition affect the properties of aluminum coils?

- The alloy composition significantly affects the properties of aluminum coils. Different alloy compositions can alter the coil's strength, corrosion resistance, electrical conductivity, and thermal conductivity. For example, adding elements like copper or magnesium can enhance the coil's strength and improve its ability to withstand high temperatures. On the other hand, alloying elements like silicon or manganese can improve the coil's corrosion resistance. Consequently, the choice of alloy composition is crucial in determining the suitability of aluminum coils for specific applications.

- Q: Can aluminum coils be used in extreme weather conditions?

- Yes, aluminum coils can be used in extreme weather conditions. Aluminum is a highly durable and corrosion-resistant material, making it suitable for various weather conditions including extreme heat, cold, humidity, and exposure to harsh elements.

- Q: Will aluminum foil go off in a metal detector

- Aluminum Detector

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q: How do aluminum coils impact energy efficiency?

- Aluminum coils play a crucial role in enhancing energy efficiency in various applications. They are commonly used in heating, ventilation, and air conditioning (HVAC) systems, refrigerators, and heat pumps. The primary reason for their positive impact on energy efficiency is their excellent heat transfer properties. Aluminum is an excellent conductor of heat, which means it can quickly absorb and dissipate thermal energy. When used in HVAC systems, aluminum coils facilitate the transfer of heat between the indoor and outdoor units. This efficient heat transfer reduces the workload on the system, allowing it to operate more efficiently and consume less energy. Additionally, aluminum coils are lightweight and have a high surface area, which further enhances their heat transfer capabilities. Their lightweight nature reduces the overall weight of the system, resulting in lower energy consumption. The increased surface area allows for greater contact between the air and the coils, promoting more effective heat exchange. Furthermore, aluminum coils are resistant to corrosion, which is a common issue in HVAC systems. Corrosion can negatively impact the efficiency of heat transfer, leading to increased energy consumption. Aluminum coils' resistance to corrosion ensures long-lasting performance, maintaining their efficiency and reducing the need for frequent maintenance or replacement. In summary, aluminum coils contribute significantly to energy efficiency by facilitating efficient heat transfer, reducing the workload on HVAC systems, and minimizing energy consumption. Their lightweight nature, high surface area, and corrosion resistance further enhance their positive impact on energy efficiency.

Send your message to us

Aluminum Roofing Coil - Aluminum Sheets AA1050 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords