Round Aluminum Foil Sheets - Embossed/Tearplates/Stucco Aluminum Sheet/Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

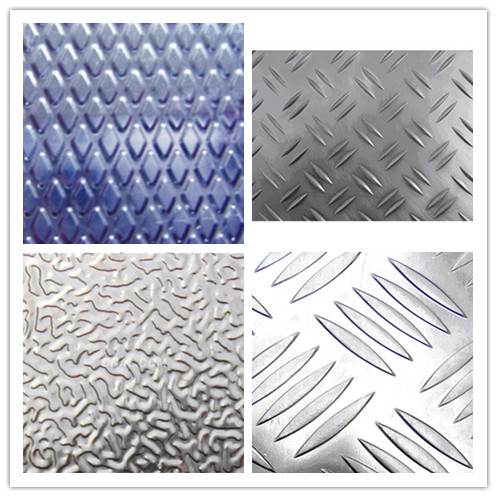

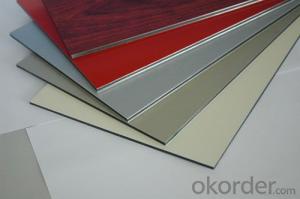

1.Structure of Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction:

Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for constructionis widely used for decorative purposes in construction, packing and appliance. Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for constructionis also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of the Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- No specific requirements this is mainly based on the actual condition is decided from the basic glass 2-5 cm bar to say what is the effect of the distance away from the glass I guess few people considered but I feel far and near to the overall effect is very small but I feel close the glass produced heat explosion probability will be reduced...

- Q: What are the common thicknesses available for aluminum sheets?

- The available thickness options for aluminum sheets vary depending on the specific application and industry requirements. Some commonly found thicknesses for aluminum sheets include 0.025 inches (0.635 mm), 0.032 inches (0.81 mm), 0.040 inches (1.02 mm), 0.050 inches (1.27 mm), 0.063 inches (1.6 mm), 0.080 inches (2.03 mm), 0.090 inches (2.29 mm), 0.125 inches (3.18 mm), 0.190 inches (4.83 mm), and 0.250 inches (6.35 mm). These thicknesses see frequent usage in industries such as construction, automotive, aerospace, and manufacturing. It should be noted, however, that specialized applications may require custom orders or fabrication to meet specific thickness requirements.

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered.

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: Can aluminum sheets be used for interior design purposes?

- Certainly, aluminum sheets are a great option for interior design purposes. The versatility of aluminum as a material offers numerous advantages when it comes to interior design applications. Its lightweight nature, durability, and resistance to corrosion make it an excellent choice for various design elements like wall coverings, ceiling panels, backsplashes, and room dividers. Aluminum sheets can be easily tailored and shaped into different forms, sizes, and finishes, providing limitless design possibilities. Moreover, aluminum is an environmentally-friendly material as it can be highly recycled. Its sleek and contemporary appearance adds a modern touch to any interior design project. In summary, aluminum sheets have gained popularity among interior designers due to their practicality, visual appeal, and sustainable nature.

- Q: I have to find the type of bond that Aluminum (foil) would have. I know that it has some kind of bond to it because that's the kind of question that I got wrong on my last quiz.

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

- Q: Can aluminum sheet be welded?

- Indeed, welding aluminum sheet is feasible. Aluminum, a versatile metal, lends itself well to welding through the utilization of diverse techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). Nevertheless, the welding of aluminum necessitates specific considerations due to its elevated thermal conductivity and low melting point when compared to other metals. Consequently, selecting the suitable welding process, filler material, and shielding gas is crucial to ensuring a successful weld. Moreover, proper surface preparation, including thorough cleaning and the removal of any oxide layer, plays a pivotal role in achieving a robust and long-lasting weld in aluminum sheet.

- Q: Are aluminum sheets suitable for electronic components?

- Yes, aluminum sheets are suitable for electronic components. Aluminum is commonly used in the production of electronic components due to its excellent conductive properties, lightweight nature, and high thermal conductivity. It is often utilized in circuit boards, heat sinks, and enclosures for electronic devices.

Send your message to us

Round Aluminum Foil Sheets - Embossed/Tearplates/Stucco Aluminum Sheet/Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords