Aluminum Sheets & Plates for Metal Ceiling System - Aluminum Rolls Cost

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Rolls Cost for Metal Ceiling System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Rolls Cost for Metal Ceiling System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

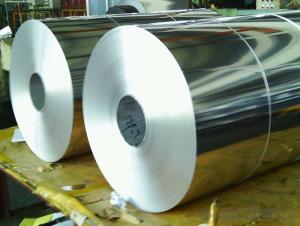

3. Aluminum Rolls Cost for Metal Ceiling System Images

4.Specification of Aluminum Rolls Cost for Metal Ceiling System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- ensure u have distilled water cuz if there is salt in it, u might finally end up freeing chlorine interior the air and die. haha. ok, take a 9 -12 volt battery or something like that and placed 2 wires from the positve and unfavourable ends interior the water. the only cord that bubbles extra is the hydrogen. so turn a attempt tube and placed it interior the water and so as that there is not any air interior the attempt tube. whilst the cord is going in, the hydrogen will fill it up and u'll be left with organic hydrogen interior the tube. i don't be conscious of if i defined it perfect yet there are a team of video clips on youtube. examine them out.

- Q: How do you join aluminum sheets together?

- One common method to join aluminum sheets together is through welding. This involves melting the aluminum at the joint and then allowing it to solidify, creating a strong bond. Other methods include using adhesive bonding, riveting, or using mechanical fasteners such as screws or bolts. The choice of joining method depends on factors such as the application, the thickness of the aluminum sheets, and the desired strength and appearance of the joint.

- Q: This question asks for methods to guarantee the safety and reliability of a project when using aluminum sheets.

- <p>To ensure your project's safety and reliability using aluminum sheets, follow these steps: 1. Choose high-quality aluminum sheets with the appropriate thickness and grade for your project's requirements. 2. Ensure proper design and engineering to withstand expected loads and stresses. 3. Use appropriate fasteners and joinery methods to secure the sheets, avoiding stress concentrations. 4. Implement corrosion protection measures such as coatings or anodizing, especially for outdoor applications. 5. Perform regular inspections and maintenance to check for signs of wear, corrosion, or damage. 6. Adhere to safety standards and regulations for aluminum construction. 7. Consult with professionals or engineers experienced in aluminum fabrication for guidance and validation.</p>

- Q: What is the typical weldability of aluminum sheets?

- The typical weldability of aluminum sheets is considered to be excellent. Aluminum is known for its high weldability due to its low melting point and thermal conductivity. It can be easily joined using various welding techniques such as TIG (tungsten inert gas), MIG (metal inert gas), and even spot welding. The weldability of aluminum sheets is further enhanced by the use of filler materials specifically designed for aluminum welding. However, it is important to note that the weldability can vary depending on the alloy composition, thickness, and surface condition of the aluminum sheet.

- Q: What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, ensuring their quality and compliance with industry requirements. Some of the commonly recognized ones include: 1. ASTM International Standards: The American Society for Testing and Materials (ASTM) has developed a range of standards specifically for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and dimensional tolerances, ensuring consistent quality across different aluminum sheet products. 2. ISO 9001: The ISO 9001 certification is a globally recognized standard for quality management systems. Aluminum sheet manufacturers that are ISO 9001 certified have demonstrated their commitment to meeting customer requirements, continuous improvement, and adherence to strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has established specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for various materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for specific defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has developed a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency across the European market. 6. RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance is crucial for aluminum sheets used in electrical and electronic equipment. This certification ensures that the aluminum sheets do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, thus guaranteeing their environmental safety. It is important for manufacturers and suppliers of aluminum sheets to comply with these standards and certifications to ensure the highest quality, safety, and suitability of their products for specific applications.

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Aluminum sheets are a great choice for food processing conveyor systems as they offer several advantages. Firstly, they are lightweight yet strong, making them perfect for conveyor systems that require frequent movement and transportation of food products. Their lightweight nature allows for easy installation, maintenance, and modification of conveyor systems, while their strength ensures the equipment's durability and longevity. Secondly, aluminum is corrosion-resistant, which is crucial in food processing environments where exposure to moisture, chemicals, and food acids is common. This resistance to corrosion ensures that the conveyor system remains hygienic and free from contamination, meeting the industry's strict food safety standards. Furthermore, aluminum is non-toxic, making it a safe material for food handling and contact. It does not react with food or release any harmful substances, ensuring the integrity and safety of the food being processed on the conveyor system. Moreover, aluminum is easy to clean and maintain, which is essential in food processing environments where hygiene is of utmost importance. The smooth and non-porous surface of aluminum sheets allows for easy removal of food particles, grease, and other contaminants, reducing the risk of bacterial growth and cross-contamination. In conclusion, aluminum sheets are highly suitable for food processing conveyor systems due to their lightweight, corrosion-resistant, non-toxic, and easy-to-clean properties. They provide a reliable and efficient means of transporting food products while ensuring the highest standards of hygiene and food safety.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: Are aluminum sheets suitable for industrial machinery?

- Industrial machinery can utilize aluminum sheets effectively. Aluminum is a versatile material that finds extensive usage in various industries, including machinery and manufacturing. Aluminum sheets possess several advantages, making them a suitable option for industrial machinery. To begin with, aluminum sheets have a lightweight characteristic. In comparison to metals like steel, aluminum boasts a significantly lower density. This attribute makes it ideal for applications where reducing weight is crucial. The lightweight nature of aluminum simplifies the handling, transportation, and installation of machinery components, resulting in enhanced efficiency and reduced costs. Additionally, aluminum sheets exhibit high resistance to corrosion. The formation of a natural oxide layer on the surface of aluminum acts as a protective barrier against corrosion. This corrosion resistance makes aluminum sheets suitable for industrial machinery, particularly in environments prone to moisture, chemicals, or harsh weather conditions. Furthermore, aluminum sheets possess excellent thermal conductivity. This property allows aluminum to swiftly and efficiently dissipate heat, rendering it suitable for applications involving machinery components that generate substantial heat. By effectively managing heat, aluminum sheets aid in averting overheating and extending the lifespan of machinery. Moreover, aluminum sheets are easily malleable and can be fabricated into various shapes and sizes, making them adaptable to diverse machinery designs and requirements. They can be effortlessly machined, welded, and joined, facilitating seamless integration into manufacturing processes for industrial machinery. Lastly, aluminum is an environmentally friendly and sustainable material. It is entirely recyclable without compromising its properties, thus minimizing the environmental impact associated with the production and disposal of industrial machinery. In conclusion, aluminum sheets are a fitting choice for industrial machinery owing to their lightweight nature, corrosion resistance, thermal conductivity, formability, and sustainability. These attributes make aluminum sheets an excellent option for a wide range of applications in the machinery and manufacturing sectors.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a lightweight and durable material, making it suitable for fencing purposes. It is resistant to rust and corrosion, making it a long-lasting option. Additionally, aluminum sheets offer a sleek and modern look to any fence.

Send your message to us

Aluminum Sheets & Plates for Metal Ceiling System - Aluminum Rolls Cost

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords