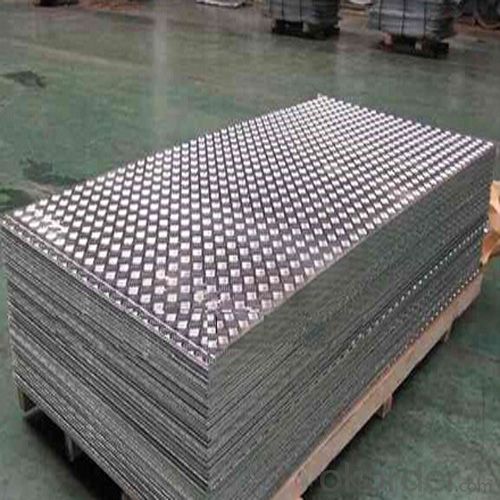

Aluminum Plate Sheets - Checked Embossed Anti-Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Checked Embossed Aluminium Plate for Antiskid Plate Description:

The aluminum embossed sheets are used in many places, transportation, decoration, construction, Packing and so on.The main products of our company are aluminium sheet, coil, aluminium embossed sheet, aluminium foil and aluminium circle. Aluminium embossed sheets include stucco embossed aluminium sheet, five-bars embossed aluminium sheet, diamond embossed aluminium sheet, etc. They are widely used in daily life.

2.Main Features of Checked Embossed Aluminium Plate for Antiskid Plate:

Aluminum Alloy Grade: 1050 1060 1100 3003 5052

Temper: H12, H14, H18, H22, H24, H26

Thickness: 0.8mm~5.0mm

Thickness tolerance: +/-0.01-0.04mm

3.Checked Embossed Aluminium Plate for Antiskid Plate Images:

4. Checked Embossed Aluminium Plate for Antiskid Plate Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1 | 0.1-0.4 | - | <0.05 | <0.05 | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | </=0.4 | 0.4 | </=0.1 | 0.4-1.0 | 4.0-4.9 | 0.25 | </=0.15 | R |

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Yes, aluminum sheets are suitable for furniture manufacturing. Aluminum is a lightweight and versatile material that offers numerous advantages for furniture production. It is corrosion-resistant, making it ideal for both indoor and outdoor furniture. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of sturdy and durable furniture pieces. It is also easy to work with, as it can be cut, bent, and welded into various shapes and designs. Moreover, aluminum can be finished with different coatings or paints to enhance its appearance and protect it from wear and tear. Overall, aluminum sheets are a viable option for furniture manufacturing due to their strength, versatility, and aesthetic appeal.

- Q: Can 101 aluminum sheets be CNC machined?

- Yes, 101 aluminum sheets can be CNC machined.

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: What is the thickness range of aluminum sheets?

- The thickness of aluminum sheets can differ based on the particular application and industry norms. Nevertheless, usually accessible aluminum sheets generally have a thickness ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). Thicker aluminum sheets may be obtainable for more specialized uses. It is crucial to bear in mind that diverse alloys and grades of aluminum may have varying thickness ranges. Therefore, it is essential to refer to the specific requirements and standards of the intended use.

- Q: What are the methods used to treat the surface of aluminum sheets to improve their properties or appearance?

- <p>Surface treatment of aluminum sheets involves various processes to enhance their properties or appearance. These include anodizing, which creates a protective oxide layer; painting, which provides a decorative and protective coating; powder coating, a durable and corrosion-resistant method; polishing, which gives a shiny finish; and etching, which creates decorative patterns. Other treatments include chemical conversion coatings, such as chromate and phosphate, for corrosion resistance, and thermal spraying for wear resistance. Each method serves a specific purpose, from improving durability to aesthetic enhancement.</p>

- Q: What are the different methods of cutting aluminum sheet?

- Some of the different methods of cutting aluminum sheet include using shears, bandsaws, jigsaws, circular saws, laser cutting, and waterjet cutting.

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating.

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- I've owned a few different bikes-- Aluminum (light but very stiff), steel (slightly heavier but far more comfortable) and Carbon Fiber (high end racing bike, extremely comfortable ride and very light). For touring and commuting I don't use the racing bike-- steel all the way. Plus, you can find great steel frames that are built for touring (surly has some great frames that I love) with attachments for all of the add-ons you'd want. At the point where you are touring you are carrying so much extra weight (panniers, bags, spare parts, etc) that an extra 5 pounds of frame weight is negligible.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets offer impressive fire-resistant qualities, making them an ideal choice for different applications that prioritize fire safety. The primary explanation for their fire resistance lies in the natural formation of a unique oxide layer on the aluminum's surface when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and reducing the likelihood of combustion. Not only is the oxide layer on aluminum sheets highly stable, but it also boasts a high melting point. Consequently, it can endure high temperatures without melting or catching fire, rendering it flame-resistant. Additionally, the oxide layer acts as an effective thermal insulator, slowing down heat transfer and impeding the spread of fire. Another benefit of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning it does not burn or support combustion. This characteristic proves especially advantageous in situations where fire containment and prevention are critical. Furthermore, aluminum sheets possess exceptional heat dissipation capabilities. They swiftly disperse heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications, including electrical enclosures, automotive parts, and industrial machinery. In conclusion, aluminum sheets demonstrate remarkable fire-resistant qualities due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These attributes make them highly sought after for applications that prioritize fire safety, offering reassurance and safeguarding against potential fire incidents.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- You are only talking about a difference of ounces between a high quality aluminum frame and a mediocre carbon frame. The difference is that you will be buying a new carbon bike in a few years when it cracks and wears out. Most of the weight of a bicycle is the components, anyway. A steel framed bike with well chosen components can be as light or lighter than a carbon framed bike with poorly chosen components. Keep in mind that carbon fiber bicycles are built for racing, and hardcore dedicated racers don't use the same bike for years at a time. The top racers don't even use the same bike for a year. I don't know about you, but i don't have a sweet sponsorship deal, so I have to buy my own bikes, and when I do buy a bike, i expect it to last a long time. Since the weight difference between a high end aluminum bike and a carbon fiber bike is pretty miniscule, factor time and cost over time in to your equation. Is a weight savings of one pound worth having to buy a new bike every three to five years instead of every ten years or more? An aluminum bike will easily last twice to three times as long as the carbon bike, so when you are doing your math, double or triple the cost of the carbon bike to see what riding on carbon will cost you over time.

Send your message to us

Aluminum Plate Sheets - Checked Embossed Anti-Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords