Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

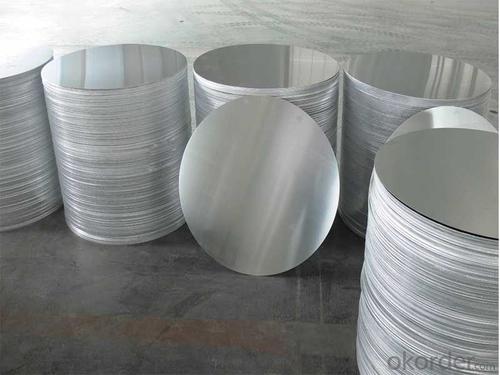

1.Structure of AA1060 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1060 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1060 D.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

3.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1060 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1060 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1060 D.C Mill Finished Aluminum Circles used for Cookware.

- Q: The difference between aluminium tubes 1060 and 6063

- 1060 is pure aluminum, 6063 is aluminum alloy, the use is different, cannot general comparison.1060 has the general characteristics of industrial pure aluminum, aluminum density, electrical conductivity, good thermal conductivity, good corrosion resistance, good plasticity, can be processed into a plate, belt, foil and extruded products, can be welding, argon arc welding, spot welding.6063 Aluminum Alloy profile with its moderate plasticity, good heat treatment strength, good welding performance and anodic oxidation treatment, surface color gorgeous many advantages and is widely used in building materials, irrigation pipe, for the vehicle, bench, furniture, elevator, fence tube, rod, etc. profile.

- Q: Do you use seamless pipes or aluminium tubes for cold storage?

- Seamless steel tubes are better than aluminium tubes, and it is recommended to use stainless steel tubes with specifications of 296 or more. The aluminum tubes will be exposed to damp air for 304 years and will oxidize and corrode.

- Q: Are aluminum pipes suitable for underground drainage systems?

- Aluminum pipes are indeed a suitable choice for underground drainage systems. Due to its lightweight and durable nature, aluminum is highly resistant to corrosion, making it an excellent option for underground applications that might encounter moisture and other elements. Moreover, aluminum pipes boast a lengthy lifespan and necessitate minimal upkeep, rendering them a cost-effective selection for drainage systems. Nonetheless, it is crucial to contemplate the precise demands of the drainage system and seek advice from professionals to ascertain if aluminum pipes are the optimal choice for the particular project.

- Q: Can 304 stainless steel aluminum pipe be welded with 6061?

- 304 stainless steel pipe6061 is aluminumWelding is difficult, it should not be fixed, consider other ways to butt it

- Q: Is the tube of LED lamp all plastic tube well or half plastic half aluminium tube?

- Of course, the power is placed inside the aluminum tube, so that the amount of LED heating plus the heating capacity of the power supply is considerable, because the power of this lamp is usually around 20W. If the power is bigger, half of the aluminum tube can not solve its heat dissipation problem. It also proposed another aluminum tube cooling fan: shaped tubes. The fan shaped aluminum frame with heat dissipation structure shape, greatly increasing the radiator area. It puts the power outside the tube so that the half of the aluminum shell is completely made into a radiator. Relative to the semicircular aluminum tube, its heat dissipation area has increased by more than 3 times. Coupled with the power does not put in the tube, but also to reduce heat, which greatly extended the life of LED.

- Q: Seamed tubes and seamless tubes under which good?

- Seamless aluminium bearing is better than welded aluminum tube, seamless texture is relatively uniform, there will be a small amount of loss in the pipe part of the chemical composition of weld, so the mechanical properties poor and seamless pipe! But not very different! Seamless pipe is recommended if it is used for elbow! The welded pipe is easy to crack! Bending radius is relatively large, then no problem!

- Q: Can aluminum pipes be used for solar panel installations?

- Yes, aluminum pipes can be used for solar panel installations. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for outdoor applications like solar panel installations. Additionally, aluminum pipes are easy to work with and can be easily customized to meet the specific requirements of solar panel mounting systems.

- Q: Can aluminum pipes be used for oil and gas pipelines?

- While steel pipes are commonly used for oil and gas pipelines because of their strength and durability, aluminum pipes can also be used for this purpose. Aluminum pipes have several advantages, including being lightweight, resistant to corrosion, and having excellent thermal conductivity. These properties make them particularly useful in situations where reducing weight is important, such as offshore or deepwater pipelines. Moreover, aluminum pipes can withstand hydrogen sulfide (H2S) corrosion, making them suitable for sour gas environments. However, it is crucial to carefully consider factors like pressure, temperature, and fluid composition before selecting the appropriate pipe material, as aluminum pipes may not be suitable for all oil and gas pipeline applications.

- Q: Expert: about 100 caliber aluminum tube, manual argon arc welding, single-sided welding, double sided forming technology. And welding process and welding method ~!

- Aluminum tube size 57*4*100; thank you all experts to answer the aluminum tube butt manual tungsten arc welding; single-sided welding double-sided forming technology......

- Q: What is the typical wall thickness of aluminum pipes?

- The typical wall thickness of aluminum pipes can vary depending on the specific application and industry requirements. However, common wall thicknesses for aluminum pipes range from 0.065 inches to 0.250 inches.

Send your message to us

Aluminum Pipes - AA1060 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches