Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1070 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

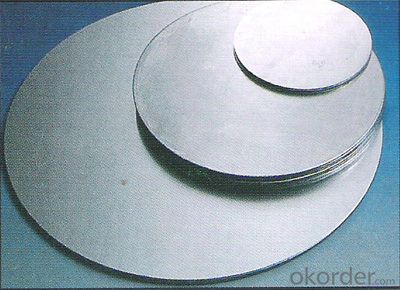

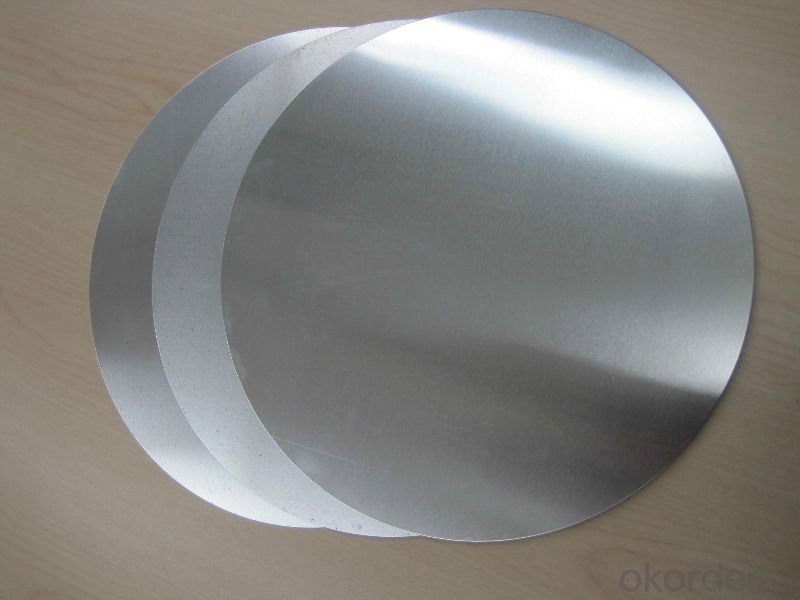

3.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q: If not, then the national standard aluminum rod and solar aluminum bar difference?

- After doing these, according to your actual installation requirements, positioning holes, drainage holes and other finishing.

- Q: Aluminum alloy after processing white spotsAluminum bar, 6061T6, diameter 92, CNC turning obvious white spots on the surface, to solve the problem.

- Like the water left after the coolant is dry, see if it can be wiped out

- Q: Synchronous wheel aluminum bar

- Synchronous pulley materials are commonly used in gray iron, 45# steel, aluminum alloy, copper or engineering plastics, etc.. 2A12 aluminum alloy is common in aluminum alloy.

- Q: What is the hardness of the aluminum rod after 7A04 anodizing?

- 2218 aircraft engine and diesel engine piston aircraft engine, cylinder head, jet engine and compressor impeller ring 2219 space rocket oxidizer tank welding, supersonic aircraft and parts, the working temperature is -270~300 degrees celsius. Good weldability, high fracture toughness, T8 state has high resistance to stress corrosion cracking, 2319, welding 2219 alloy electrode and filler solder, 2618 die forgings and free forgings. The piston and engine working temperature of 2A01 is less than or equal to 100 degrees Celsius structure rivet 2A02 working temperature is 200~300 degrees Celsius turbojet engine 2A06 axial compressor blade working temperature of 150~250 degrees Celsius, aircraft structure and working temperature of aircraft structures 125~250 degrees Celsius rivet 2A10 than 2A01 alloy with high strength, for structural parts, propeller blades, transportation and architectural structure of moderate intensity manufacturing working temperature is less than or equal to 100 degrees Celsius in the structure of the 2A11 aircraft aircraft rivet. Medium strength aircraft bolts and rivets 2A12 aircraft skin and frame, ribs and spars, rivets, construction and transportation structure of 2A14 complex shape free forging and die forging 2A16 working temperature of 250~300 degrees Celsius, aircraft and spacecraft parts, working at high temperature and room temperature welding container and sealed cabin 2A17 the working temperature of 225~250 Celsius at the end of the 2A50 aircraft parts of complex shape parts of medium strength 2A60 aircraft engine compressor wheel, wind wheel, fan, impeller and other 2A70 aircraft, aircraft engine piston, air guide wheel, wheel 2A80 aero engine compressor blade, impeller, piston, piston ring and other parts of the high temperature air 2A90 engine piston

- Q: How long is the length of the aluminum rod used in the production of the aluminum alloy line?

- As long as we know the rice weight of the aluminum rod used and the theory of the extruded section, we should choose the right length of aluminum bar

- Q: Aluminum bar furnace to the temperature does not cease fire, what's the matter?

- Abnormal judgement and basic maintenance of aluminium rod furnace temperature control instrument:1, to determine whether the normal temperature control instrument, at the time of heating will lower the temperature to the temperature control table, to see whether the burning burning machine, to check whether the normal temperature table, under heating condition, the lower the temperature to the temperature below the temperature, and then look at the burner is not in combustion, if not that there was no abnormal combustion temperature table, otherwise please repair personnel to repair. ?2, regular temperature table surface dust wipe clean, do not let the thermostat with water or other stolen goods. Check thermocouples regularly to see if there is any abnormality.

- Q: The difference between die cast aluminum and extruded aluminium rods

- The standard production process of aluminum extrusion production line of aluminum rod rod can be divided into casting workshop, mold workshop, extrusion workshop (a) / (two), aging workshop, packaging workshop, warehouse, warehouse. The company's total aluminum rod production processes: casting workshop, aluminum rod extrusion workshop warehouse and Aging Workshop and packaging workshop warehouse to warehouse workshop, the following were casting extrusion workshop, workshop, re aging analysis.

- Q: Is pure aluminum not the raw material? Why are pure aluminum rods hollow? Time consuming and exhausting. Who can introduce?!!! Thank you!! (the country has banned the export tax refund of pure aluminum products). Why is the product still exported to Korea and Japan?.

- Aluminum smelting needs to consume a great deal of energy (three aluminium oxide two) in electrolytic molten state, while pure aluminum is mainly used as industrial raw material for export, with low added value, so the country does not encourage export.

- Q: The difference between the o state and the h112 state of aluminum bars

- Suitable for fully annealed products with minimum strength (occasionally) H work hardening.

- Q: Does the smell of burning aluminum bars often affect fertility?

- It will be! Although aluminum is not heavy metals, it belongs to non-ferrous metals! Too much absorption is harmful to the human body

Send your message to us

Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches