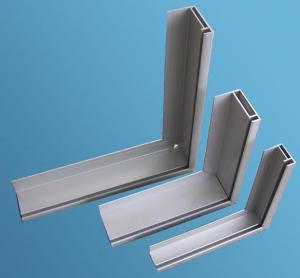

Aluminum Pipes Vehicle Body Frame

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: What are the different surface finishes available for aluminum pipes?

- Some of the different surface finishes available for aluminum pipes include mill finish, anodized finish, powder coated finish, polished finish, and brushed finish.

- Q: Hello, there's a question I'd like to ask. 'I'd like an aluminum pipe bender', but it won't do '

- Landlord: actually, this is very simple to solve, you just need to find the root of thin wire, according to the drawings by hand bend again, then according to your bending appearance, can according to your order of elbow bending on pipe bender, as long as you do a few times, clear topspin, backspin!

- Q: The same size or different specifications of the square aluminum tube, T how to connect more beautiful ah?!

- According to the precision points: ordinary aluminum tube and precision aluminum tube, in which the precision aluminum tube generally needs to be processed after extrusion, such as cold drawn, fine drawn, rollingBy thickness: ordinary aluminum tube and thin-walled aluminum tubePerformance: corrosion resistance, light weight.

- Q: What is the difference between the aluminum tube connection and the copper tube connection of the air conditioner?

- The aluminum pipe leaks easily and the copper pipe leaks less!

- Q: Are aluminum pipes resistant to impact damage?

- Aluminum pipes, in general, display resistance to impact damage. The reason lies in aluminum's remarkable strength-to-weight proportion, which renders it a material that is both durable and lightweight. It possesses a commendable ability to withstand moderate levels of force without deformation or breakage. Nonetheless, the precise degree of impact resistance can differ according to the specific grade and thickness of the aluminum pipe. Thus, in situations that involve high levels of stress, it might be essential to fortify the pipe or explore alternative materials. On the whole, aluminum pipes prove to be a dependable option for various applications that prioritize the prevention of impact damage.

- Q: How to control the hardness of aluminum pipe?

- The corrosion resistance is not high, in order to improve the corrosion resistance of anodic oxidation treatment and often used methods of paint or aluminum surface layer.

- Q: How do you usually process hollow aluminum tubes? I want to make aluminum tubes myself

- What material to see? There are many kinds of aluminumAskI used it for unpowered delta wings. What type of aluminum is light, strong and cheap?. Domestic materialChasing the answerZL204

- Q: Can you tell me what kind of pipe bender is used to bend the aluminum tube? It's not easy to wrinkle or break

- The second point: do not use the hydraulic bender with fast bending speed to avoid the wrinkling and bending of flat tubes! The third point: the use of rotating pipe bending equipment, do not bend and bend the pipe bending equipment! Fourth: special die set for bending aluminium tube!

- Q: Do aluminum pipes require any special tools for installation?

- Yes, aluminum pipes may require special tools for installation. These tools can include pipe cutters, deburring tools, reaming tools, and crimping tools. Pipe cutters are necessary to accurately cut the aluminum pipe to the desired length. Deburring tools help remove any rough edges or burrs on the cut ends of the pipe, ensuring a smooth connection. Reaming tools are used to enlarge the inside diameter of the pipe, allowing for easier insertion of fittings or connectors. Crimping tools are typically used to create secure and leak-proof connections between aluminum pipes and fittings. It is important to use the appropriate tools for aluminum pipe installation to ensure a proper and reliable plumbing system.

- Q: Steel pipe can flange connection, aluminum pipe can flange connection? How about copper tubes?

- Both flanges can be connected. The flange is the joint of the pipe and the pipe.Different media, the choice of flange material is different.You say plastic pipes can also come through flanges. Flanges are usually made of nonmetallic material.Teflon can also be done. The wear resistance of PTFE is chenchen.

Send your message to us

Aluminum Pipes Vehicle Body Frame

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches