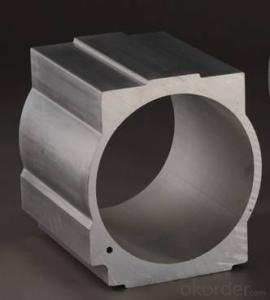

Aluminum Air Cylinder Shell with Aluminum Pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

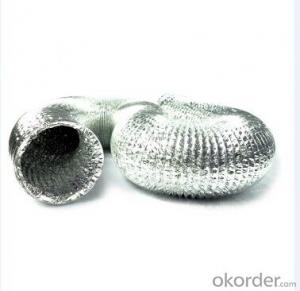

- Q: 0 `# U5 T4 J* Z+ M+ P& F5 "| _# G& _ now refrigeration accessories vendors, sales are not heat shrinkable aluminium outer protective sleeve, is coated with a layer of red things, do not know how long can use aluminum `# O4 ` (C (g$Q8 u b heat shrinkable tube can be used for long v$! D/ J'B. Q;}; C']

- The sky see now actually used outside heat shrinkable tubes of the copper tube, do not look carefully thought is copper

- Q: Aluminum pipe oval what reason?

- Can the United States control it? Don't issue so much Treasury debt and the United States has too much debt. Don't you worry that you can't afford a default?.

- Q: The refrigerator can be used in soldering aluminum crack? Repair a Haier refrigerator, found that there is a little cracks in the aluminum tube in the freezer. Can solder wire be used to repair it?

- Certainly not for solder wire Lo, can move a little cushion water temperature is low, iron cloth flame is very short, prepare a fix, it is open and close back the money, can not move back out on the open

- Q: What are aluminum pipes made of?

- Aluminum pipes consist mainly of aluminum, a metal that is both lightweight and resistant to corrosion. The process of extracting aluminum from bauxite ore and refining it through a series of procedures yields pure aluminum. This pure aluminum is subsequently melted and shaped into cylindrical forms to manufacture aluminum pipes. The addition of different alloys is possible to improve the strength, durability, and various other characteristics of the aluminum pipes, based on their intended purposes. In summary, aluminum pipes are primarily made of aluminum, rendering them suitable for diverse applications across industries like construction, automotive, aerospace, and plumbing.

- Q: Titanium tube pressure or aluminum tube withstand voltage?

- It depends on how to compare, pure titanium tube or titanium alloy tube? Pure aluminum tube or aluminium alloy tube? Titanium alloys and aluminium alloys are divided into many grades.

- Q: How do aluminum pipes compare to plastic pipes in terms of durability?

- Aluminum pipes generally offer higher durability compared to plastic pipes. Aluminum is a stronger and more rigid material, making it less prone to cracking, warping, or breaking under pressure or extreme temperatures. Additionally, aluminum pipes have a longer lifespan and are less susceptible to degradation from UV exposure or chemical reactions. However, plastic pipes may be more resistant to corrosion and are often cheaper and easier to install. The choice between aluminum and plastic pipes ultimately depends on the specific application and desired durability requirements.

- Q: Are aluminum pipes suitable for desalination plants?

- Yes, aluminum pipes can be suitable for desalination plants. Aluminum is a lightweight, corrosion-resistant material that can withstand the harsh conditions of desalination plants, which involve high-pressure and corrosive seawater. Aluminum pipes have excellent resistance to saltwater corrosion, making them a reliable choice for conveying saltwater throughout the desalination process. Additionally, aluminum pipes are easy to install, require minimal maintenance, and have a long lifespan, making them a cost-effective option for desalination plants.

- Q: What are the different surface treatments available for aluminum pipes?

- There are several surface treatments available for aluminum pipes, each serving different purposes and providing unique benefits. Some of the commonly used surface treatments for aluminum pipes include anodizing, powder coating, painting, polishing, and chromate conversion coating. Anodizing is a popular surface treatment method that involves creating a protective oxide layer on the aluminum surface. This process not only enhances the corrosion resistance of the pipe but also provides a decorative finish. Anodized aluminum pipes are known for their durability and resistance to wear and tear. Powder coating is another widely used surface treatment for aluminum pipes. In this process, a dry powder is applied electrostatically and then cured to create a hard, protective coating. Powder coating not only enhances the appearance of the pipe but also provides excellent resistance to chemicals, UV rays, and impacts. Painting is a traditional surface treatment method that involves applying liquid paint to the aluminum surface. This treatment not only enhances the aesthetics of the pipe but also provides protection against corrosion and environmental factors. Painting is a versatile option as it allows for a wide range of colors and finishes. Polishing is a surface treatment method that involves buffing the aluminum surface to achieve a smooth and reflective finish. This treatment is commonly used for decorative purposes, as it enhances the appearance of the pipe by giving it a sleek and shiny look. Chromate conversion coating, also known as chemical conversion coating, involves applying a thin layer of chromate on the aluminum surface. This treatment enhances the corrosion resistance of the pipe and provides a good base for subsequent painting or powder coating. In summary, the different surface treatments available for aluminum pipes include anodizing, powder coating, painting, polishing, and chromate conversion coating. Each treatment offers specific benefits such as improved corrosion resistance, enhanced aesthetics, and increased durability. The choice of surface treatment depends on the intended application and desired outcome for the aluminum pipes.

- Q: Can aluminum pipes be used for airport terminals?

- Yes, aluminum pipes can be used for airport terminals. Aluminum is a popular material choice for various applications in airport terminals due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during construction and installation. This can lead to cost savings and faster project completion times. Additionally, aluminum pipes are corrosion-resistant, which is crucial in environments like airport terminals where exposure to moisture, humidity, and chemicals is common. This resistance to corrosion ensures the longevity and durability of the pipes, reducing maintenance and replacement costs in the long run. Another advantage of using aluminum pipes in airport terminals is their excellent thermal conductivity. Aluminum pipes can efficiently transfer heat, making them suitable for applications such as heating, ventilation, and air conditioning (HVAC) systems. This property can contribute to energy efficiency and cost savings for the terminal's operations. Furthermore, aluminum is a sustainable material as it is easily recyclable. This aligns with the increasing emphasis on environmental responsibility in modern construction practices. By using aluminum pipes, airport terminals can contribute to sustainable building practices and reduce their carbon footprint. In summary, aluminum pipes can be effectively used in airport terminals due to their lightweight nature, corrosion resistance, thermal conductivity, and sustainability. Considering these advantages, it is a suitable material choice for various applications within airport terminal infrastructure.

- Q: Are aluminum pipes affected by exposure to fire or flames?

- Aluminum pipes, upon exposure to fire or flames, experience effects. Being a non-combustible material, aluminum does not ignite or burn independently. Nevertheless, the intense heat can still impact aluminum pipes when subjected to high temperatures. With a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum may begin to soften and distort under the extreme heat of a fire. Consequently, this can result in structural harm and compromise the pipes' integrity, potentially leading to leaks or failure. Hence, it is crucial to exercise caution and safeguard aluminum pipes against direct contact with fire or flames to ensure their durability and functionality.

Send your message to us

Aluminum Air Cylinder Shell with Aluminum Pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords